Metal roof truss having generally s-shaped web members

a technology of metal roof trusses and web members, which is applied in the direction of girders, joists, trusses, etc., can solve the problems of increasing the cost of manufacture and production of metal trusses, c-shaped members are prone to flexural torsional buckling, and hot-rolled members are more expensive to manufacture than cold-rolled members. , to achieve the effect of improving the strength and performance of web members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

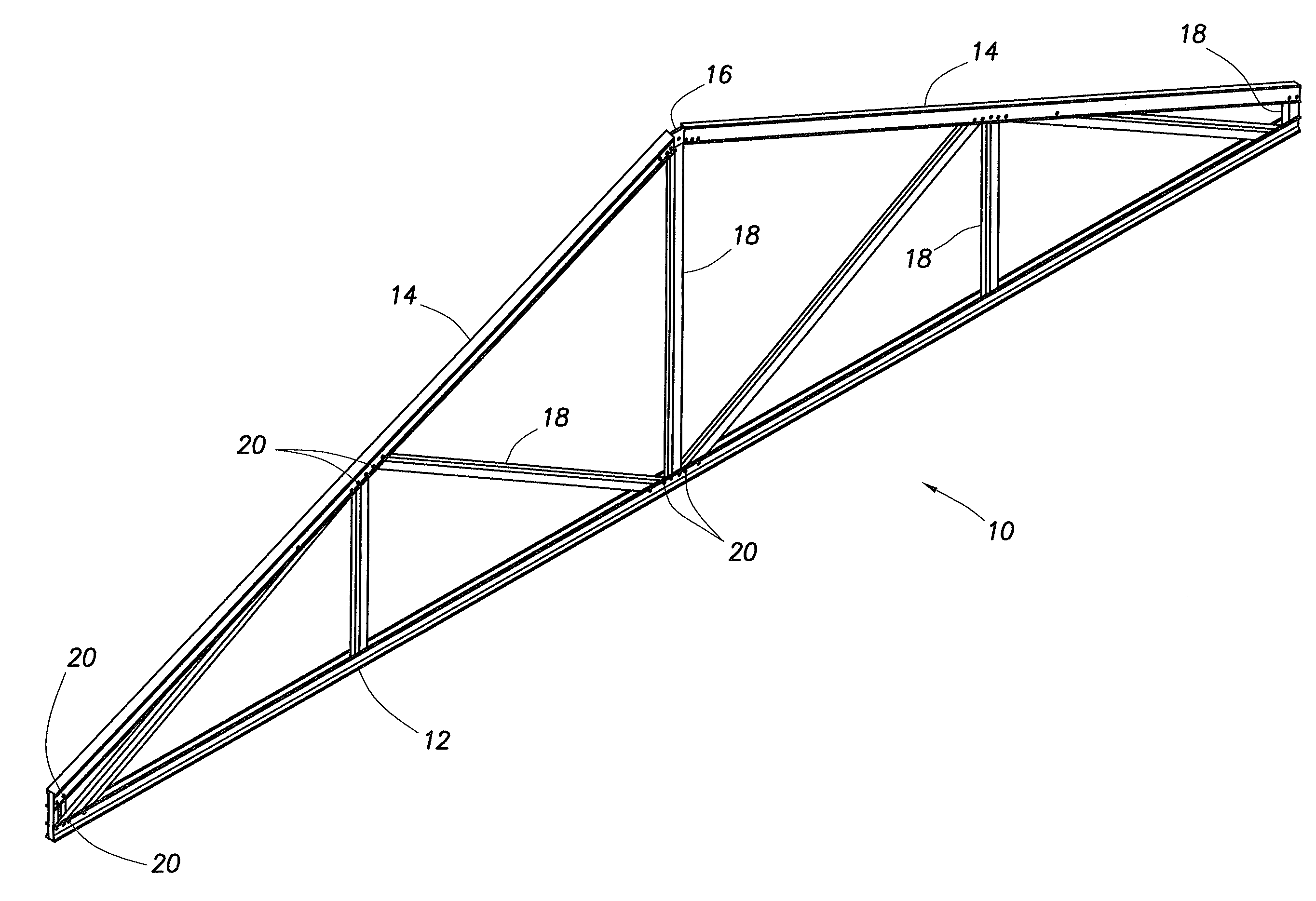

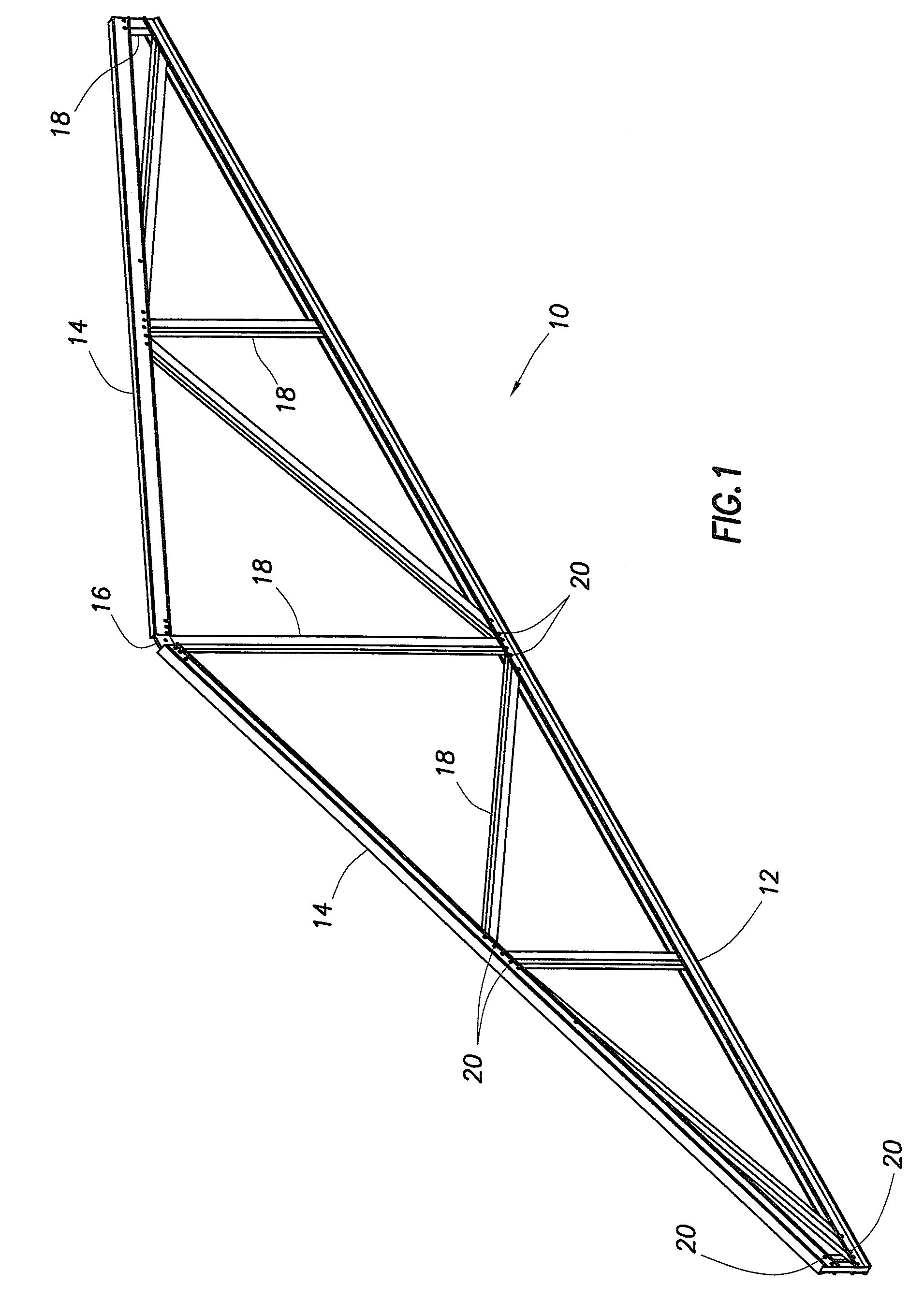

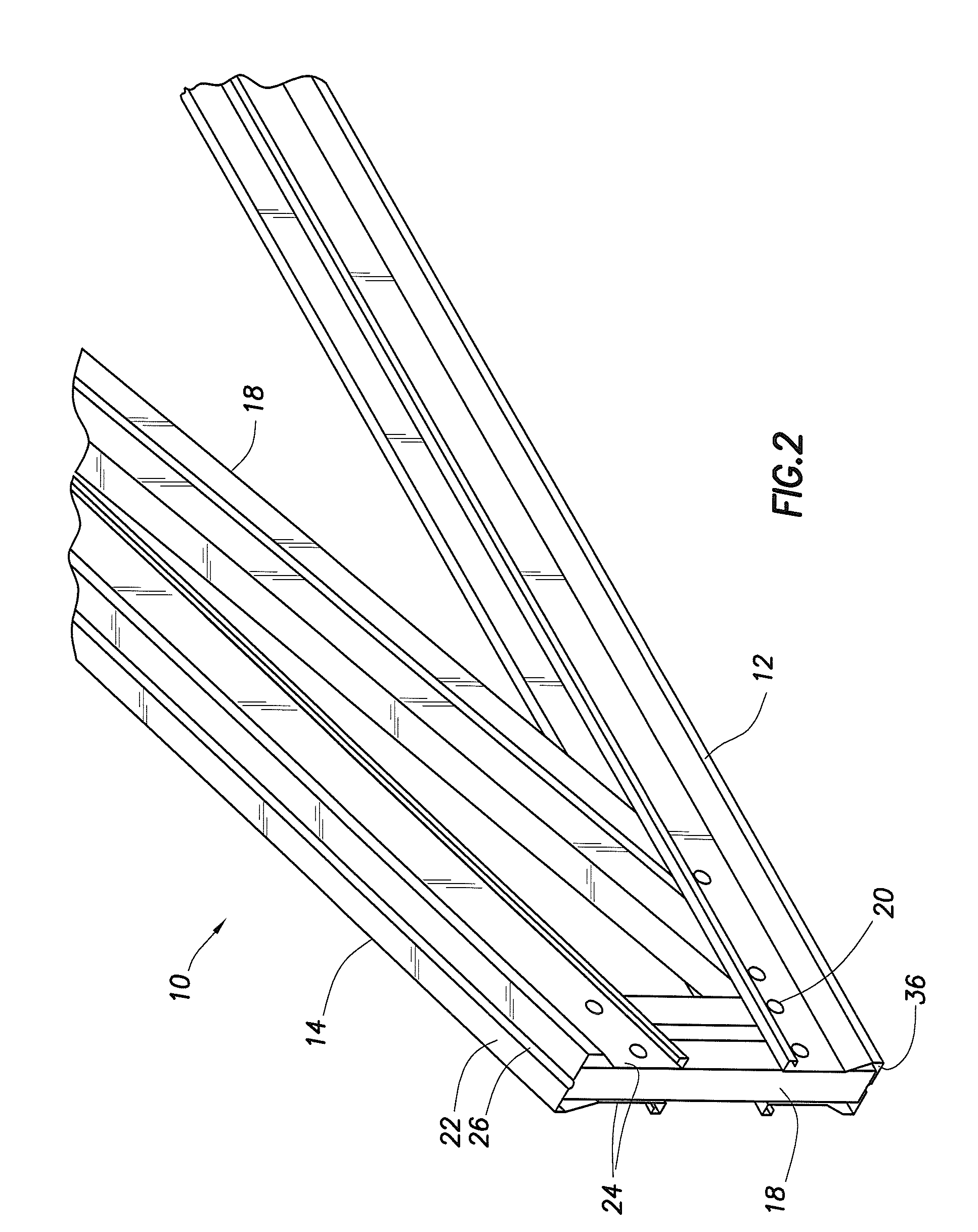

[0024]FIG. 1 is a perspective view of an exemplary metal truss 10. The truss 10 typically employs a bottom or lower chord 12 and two top or upper chords 14. The upper chords 14 are attached to one another at peak 16 by various means known in the art. The upper chords 14 and lower chord 12 are attached to one another, either directly using some means of attachment, or indirectly, through web members 18, as shown. A typical metal roof truss 10, as seen in FIG. 1, has two elongated, diverging upper chords 14 arranged opposed to one another. It is also possible to employ a single upper chord for flat roofs, floor trusses and the like, or three or more upper chords for more complicated or lengthy trusses. Typically, a single lower chord 12 is employed, however, it is also possible to employ two or more lower chords to provide extra length or allow for a truss having a vaulted design and the like.

[0025]Web members 18 and chords 12 and 14 are attached to one another. Multiple elongated met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com