High-performance daily-use ceramic for dishwashing machine and preparation method of daily-use ceramic

A high-performance, dishwasher-safe technology, applied in the field of ceramic materials, can solve the problems of poor dishwasher-resistant performance, and achieve the effects of improving safety, easy industrial application and promotion, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

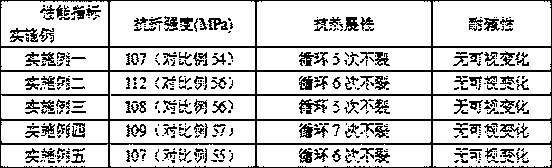

Examples

Embodiment 1

[0025] 1. The present embodiment is a high-performance daily-use ceramics for dishwashers, which is composed of a daily-use ceramic body and a coating covering its surface.

[0026] The raw materials of the ceramic body for daily use are 30 wt% of Jiepai soil, 27 wt% of quartz, 20 wt% of Datong soil, and 23 wt% of feldspar.

[0027] The slurry of coating is made up of base material and binder solution according to weight ratio base material: binder solution=1: 1.2; 1200 mesh) 50 wt%, MgO 15 wt%, zirconium silicate 5 wt%, spodumene 10 wt%, binder solution is PVA solution, its concentration is 0.5 wt%.

[0028] 2. The preparation method of the above-mentioned high-performance household ceramics for dishwashers in this embodiment, the steps are as follows:

[0029] (1) Preparation of daily-use ceramic body: According to the ingredients of the raw materials of the above-mentioned daily-use ceramic body, wet ball milling (ingredients: ball: water = 1:2:0.5), sieving to remove iron...

Embodiment 2

[0035] The present embodiment is a kind of high-performance daily-use ceramics for dishwashers and a preparation method thereof, which differs from Embodiment 1 in that:

[0036] (1) The slurry of the coating in this example, the raw material composition of the base material is 22 wt% of nano-alumina, 53 wt% of quartz micropowder (with a particle size of 800-1200 mesh), 15 wt% of MgO, and 3 wt% of zirconium silicate %, spodumene 7 wt%; the binder solution is a PVB solution with a concentration of 0.9 wt%.

[0037] (2) In step (3) of the preparation method of this embodiment, the coating thickness of the coating is 0.15 mm.

[0038] (3) In step (4) of the preparation method of this embodiment, the heating rate is 4°C / min, the holding time is 30min, and the calcination temperature is 1320°C.

Embodiment 3

[0040] The present embodiment is a kind of high-performance daily-use ceramics for dishwashers and a preparation method thereof, which differs from Embodiment 1 in that:

[0041] (1) The raw materials of the daily-use ceramic body in this example are 25 wt% of Jiepai soil, 25 wt% of quartz, 25 wt% of Datong soil, and 25 wt% of feldspar.

[0042] (2) The slurry of the coating in this example, the raw material composition of the base material is 17 wt% of nano-alumina, 52 wt% of quartz micropowder (with a particle size of 800-1200 mesh), 11 wt% of MgO, and 8 wt% of zirconium silicate %, spodumene 12 wt%; the binder solution is a PVB solution with a concentration of 0.9 wt%.

[0043] (3) In step (1) of the preparation method of this embodiment, the bisque firing temperature is 800°C.

[0044] (4) In step (3) of the preparation method of this embodiment, the coating thickness of the coating is 0.25 mm.

[0045] (5) The high-performance daily-use ceramics for dishwashers prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com