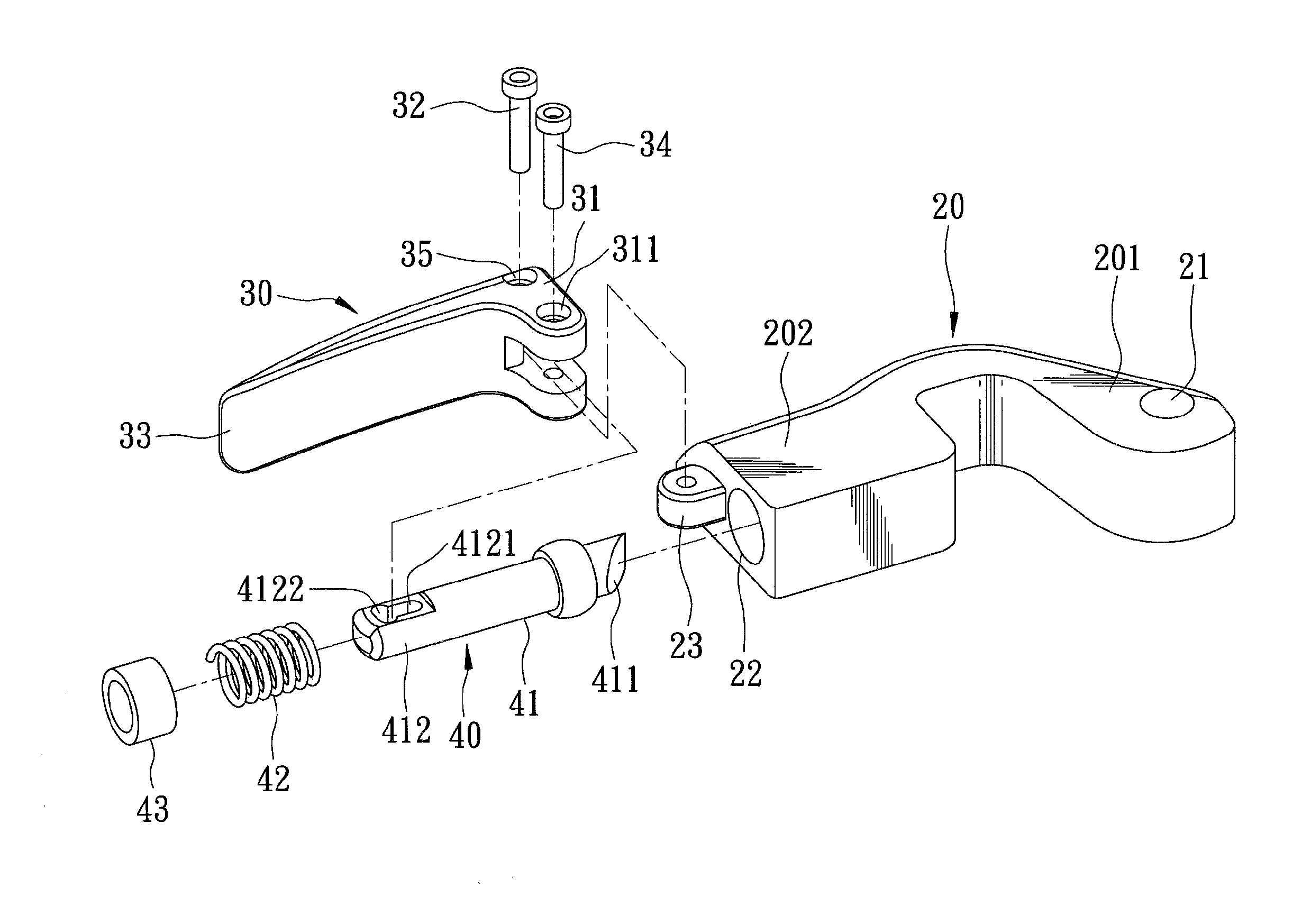

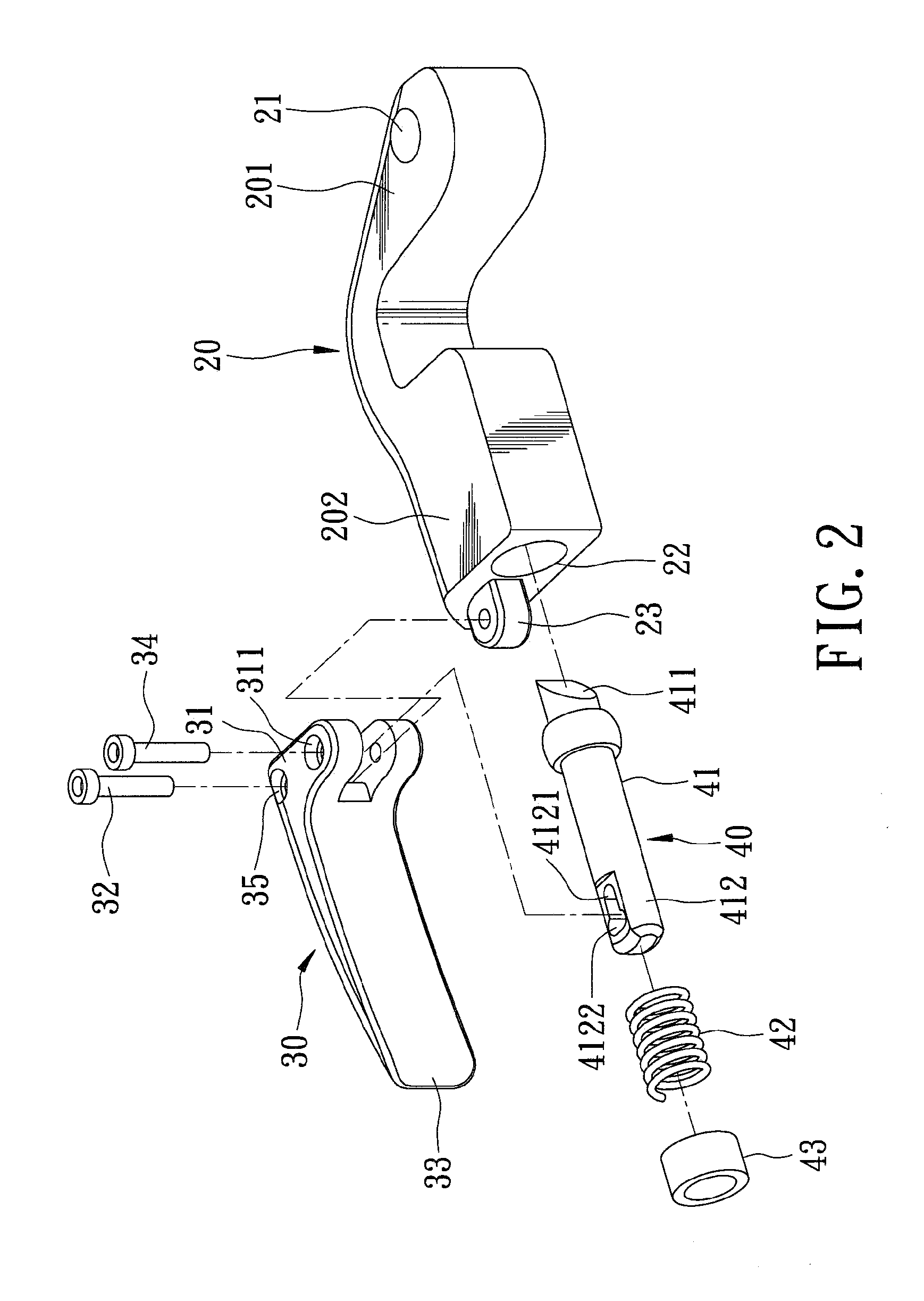

Easily unlatchable cam-lock actuating device for use in a locking coupling assembly that couples two tubular members

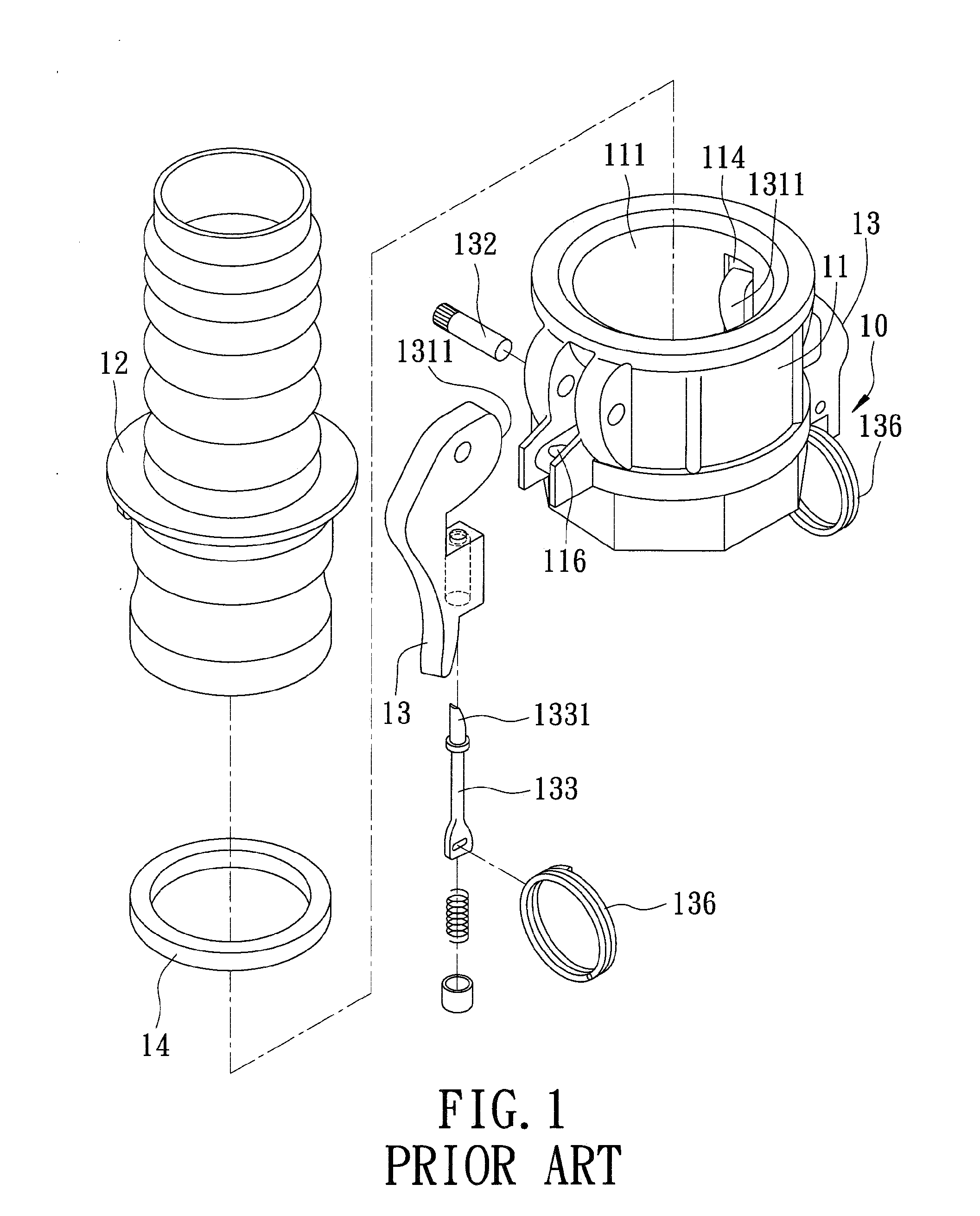

a technology of cam-lock and actuating device, which is applied in the direction of couplings, mechanical equipment, etc., can solve the problems of uncomfortable user grip and pulling of the pull ring 136

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0039]Referring to FIGS. 9 to 11, the second preferred embodiment of an easily unlatchable cam-lock actuating device according to this invention is similar to the previous embodiment in construction. In the second embodiment, the latch shank 41 has a pressed wall 413 which is spaced apart from the latch end 411 along the lengthwise line by a space 414. The weight end 31 of the releasing lever 30 is configured to extend into the space 414 to press the pressed wall 413 so as to permit the latch end 411 to be retracted and to be disengaged from the cavity 103 when the power end 33 is turned to the unlatched position, as shown in FIG. 12. In addition, the counter-force generating mechanism includes a retaining wall 24 which is disposed on the arm body 202 and which is spaced apart from the fulcrum axis 32, and a friction region 37 which is disposed on the releasing lever 30 and which is angularly displaced from the weight end 31 about the fulcrum axis 32 such that, as a result of displa...

third embodiment

[0040]Referring to FIGS. 13 to 16, the third preferred embodiment of an easily unlatchable cam-lock actuating device according to this invention is similar to the previous embodiments in construction. In the third embodiment, the weight end 31 of the releasing lever 30 includes a friction segment 312 extending from the fulcrum portion 35, and a pressing segment 313 which is pivotably mounted on the friction segment 312 by a pivot pin 38 about a turning axis parallel to the fulcrum axis 32, and which has a first cam surface 314. The latch shank 412 has a second cam surface 415 which mates with the first cam surface 314 such that, as shown in FIG. 17, turning of the power end 33 about the fulcrum axis 32 toward the unlatched position results in transverse movement of the pressing segment 313 relative to the lengthwise line to thereby permit the latch end 411 to disengage from the cavity 103. In addition, the counter-force generating mechanism includes a friction wall 315 which is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com