Last for manufacturing a shoe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

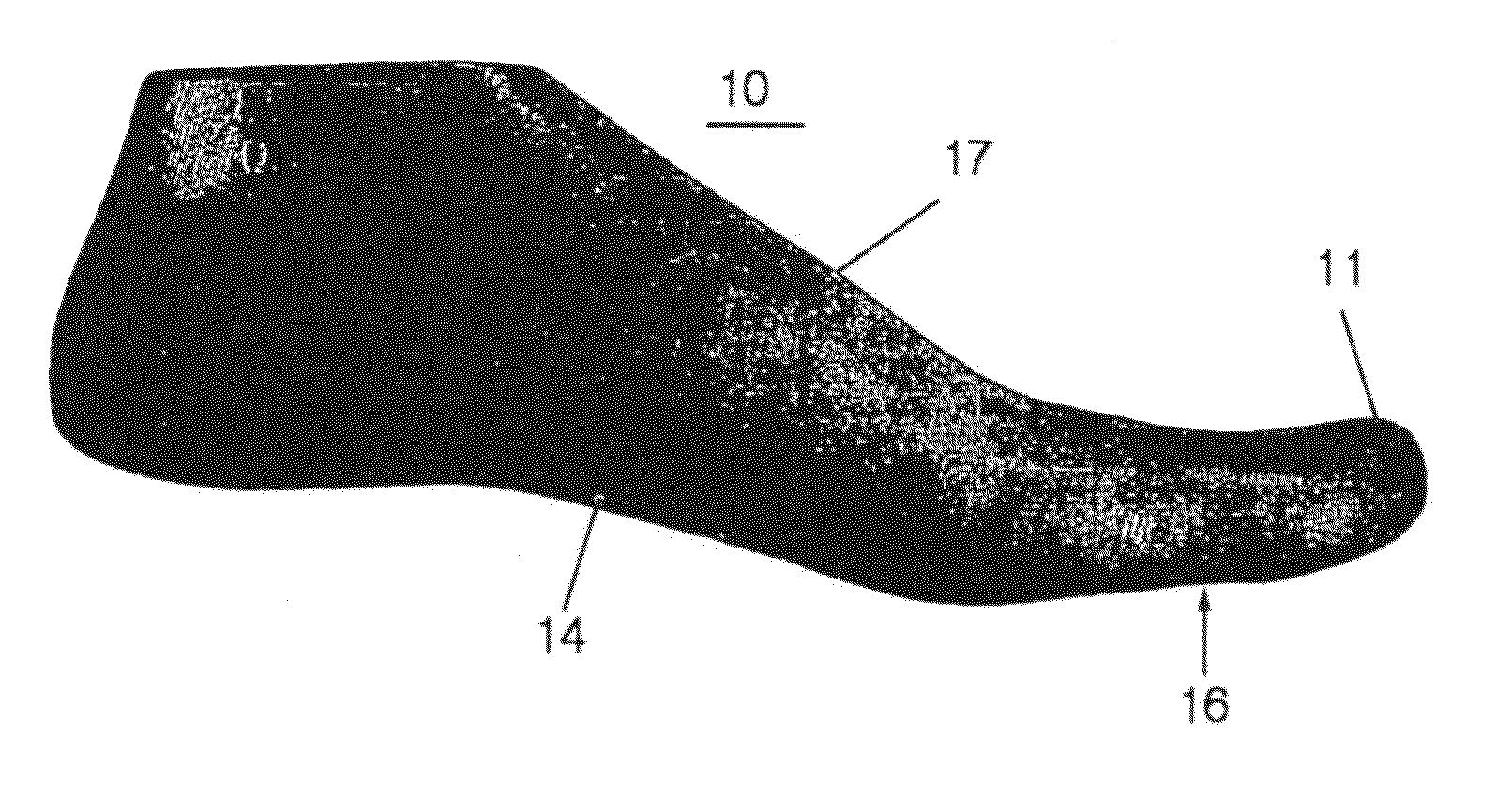

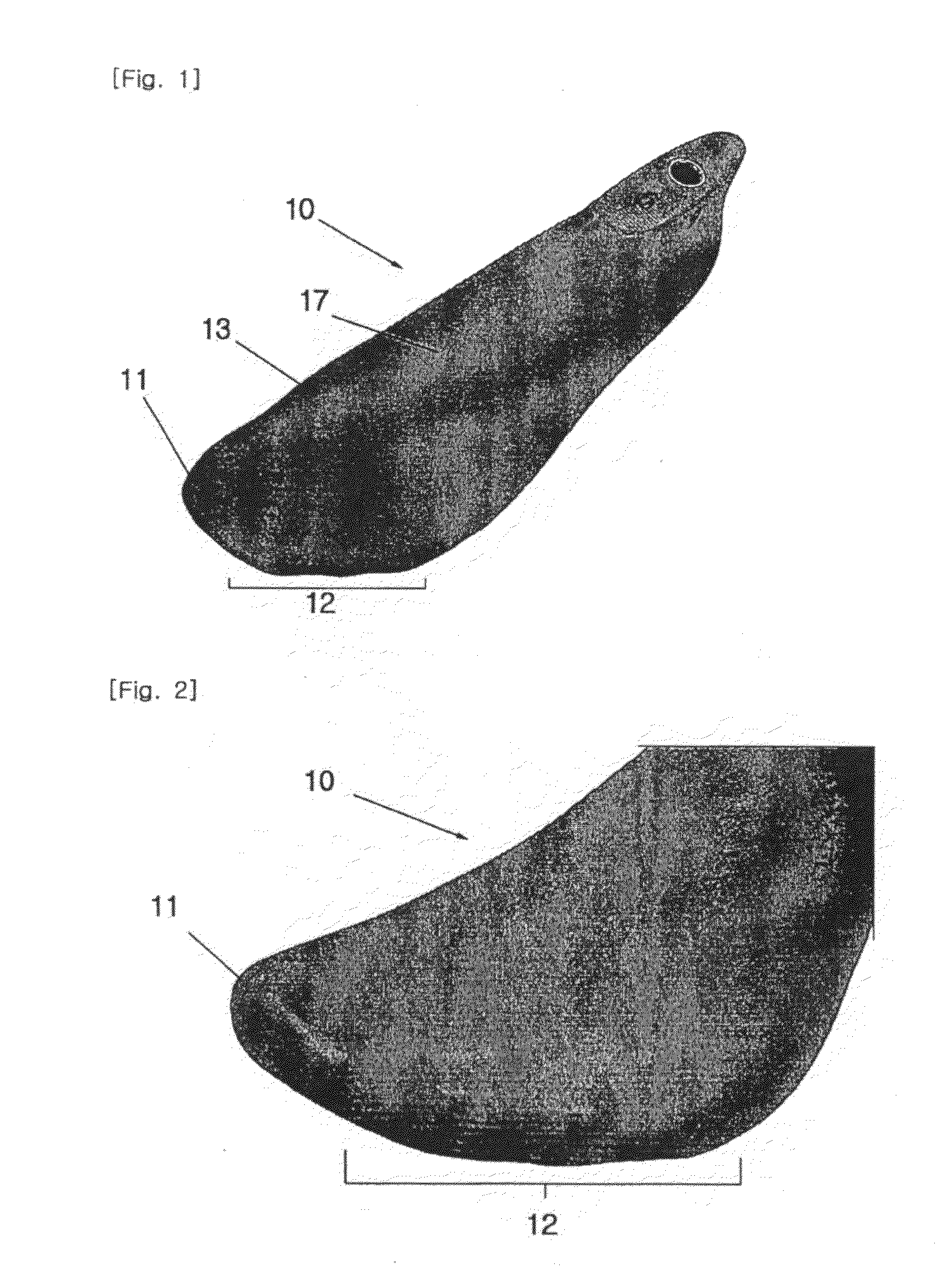

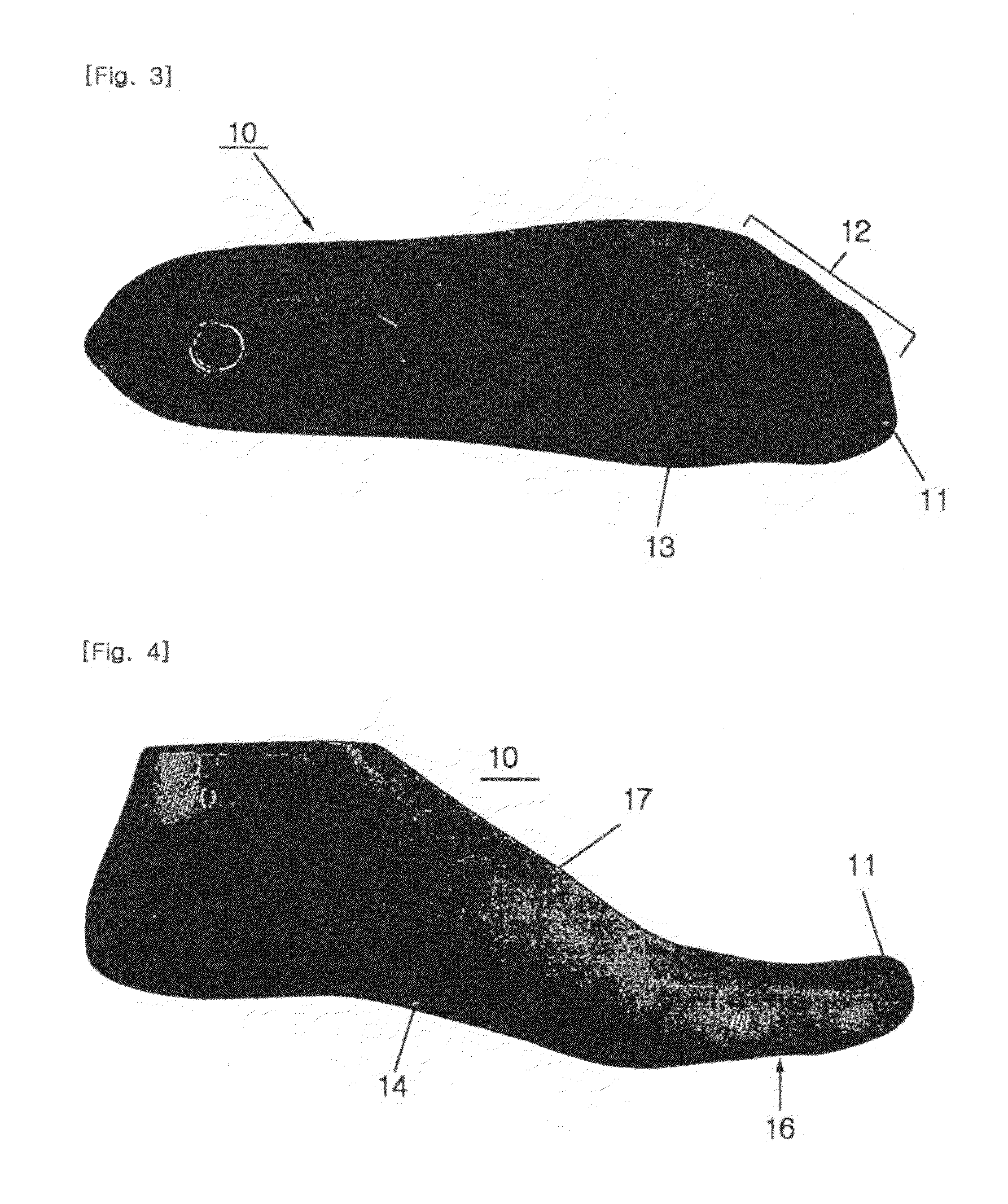

REFERENCE SIGNS LIST

[0026]10 . . . Last[0027]11 . . . First protruding portion[0028]12 . . . Convex-concave portion[0029]13 . . . Second protruding portion[0030]14 . . . First concave portion[0031]15 . . . Third concave portion[0032]16 . . . Second concave portion[0033]17 . . . Third protruding portion[0034]21 . . . The forefoot[0035]22 . . . The midfoot[0036]23 . . . The rearfoot

DESCRIPTION OF EMBODIMENTS

[0037]The present inventor studies the pressure of foot and shape change in bionics resources, and reflected the said study. The present invention is characterized in its construction of the last (10) embodying human body shape as it stands. Specifically, it selectively forms the forefoot (21) of last for manufacturing a shoe, the first protruding portion (11) in a round form at the front and upper direction corresponding to a big toe shape, convex-concave portion (12) corresponding to each protruding shapes of the second or fifth toe of the forefoot of the above last, the midfoot ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap