Multi-pack traveler component package insert

a technology of multi-pack traveler and component package, which is applied in the directions of transportation and packaging, rigid containers, tray containers, etc., can solve the problems of blister packages and the contents of primary packages can be dangerous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

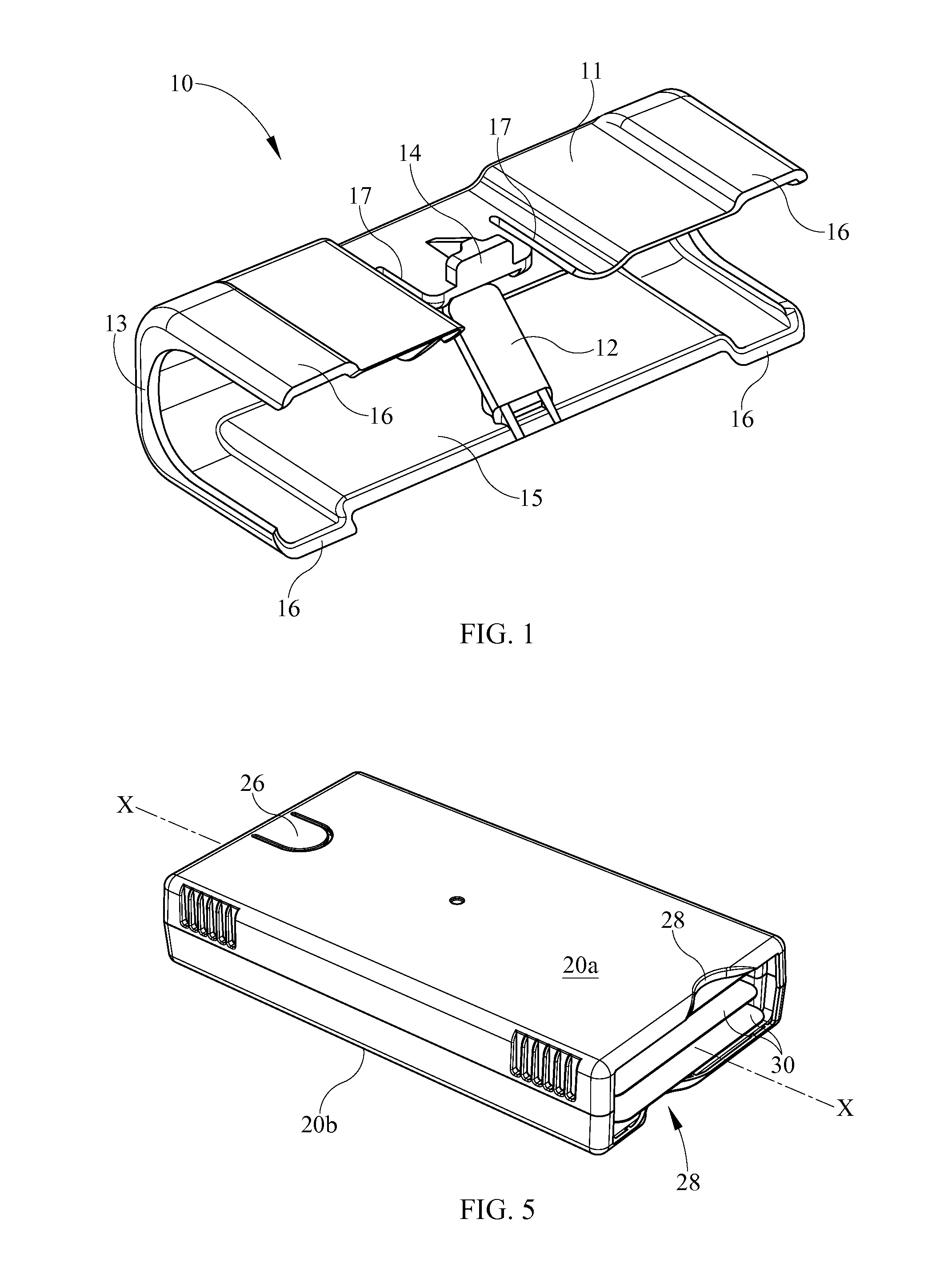

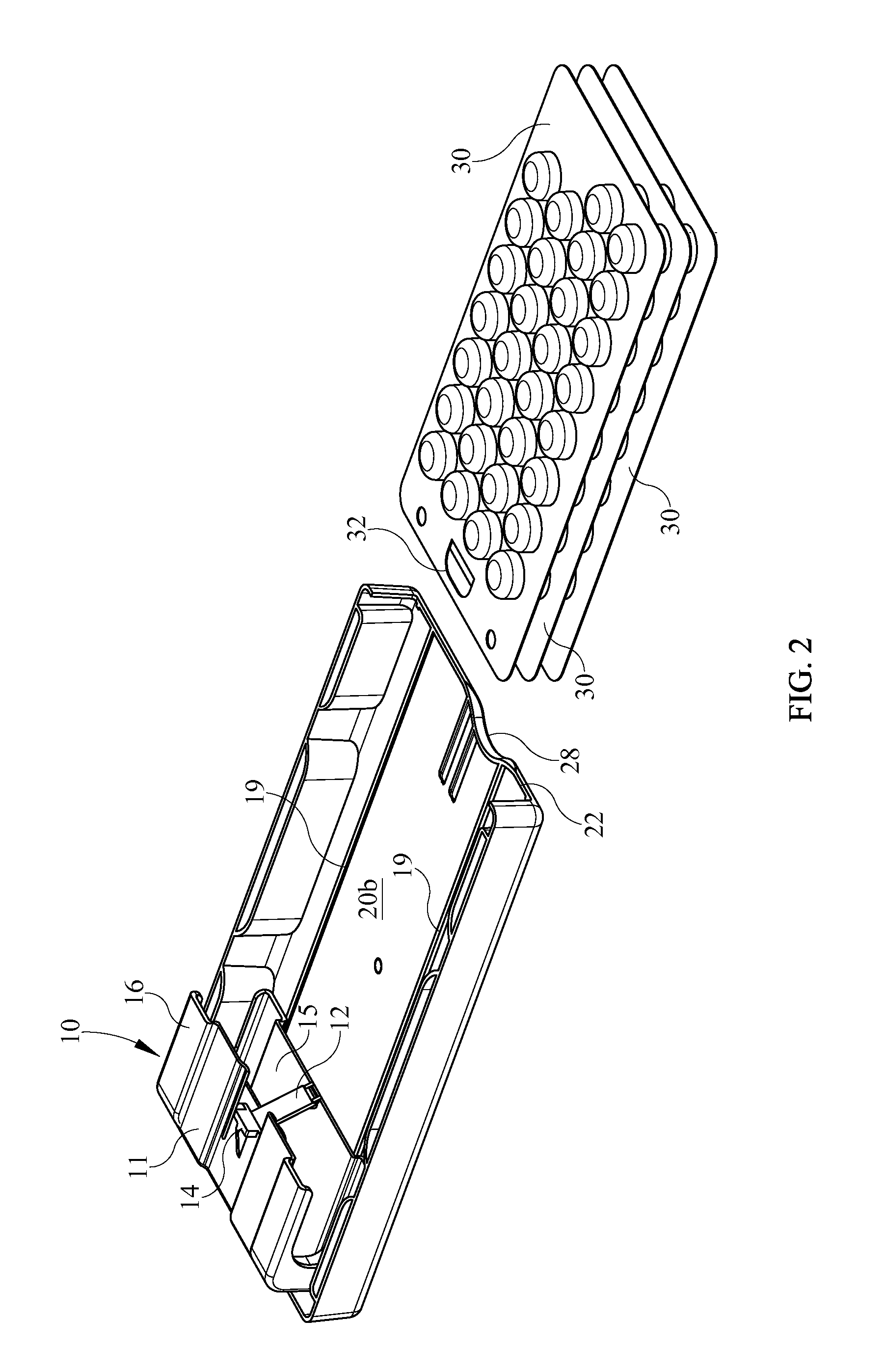

[0029]FIG. 1 is a perspective view of a traveler clip 10 designed to use with the aforementioned packaging apparatus according to the disclosure. The purpose of the traveler clip 10 is to (1) engage or bind one or more blister packages together, and (2) slidably and securely engage with a sleeve such that the one or more blister packages can be accessed by a user of the packaging apparatus.

[0030]The traveler clip 10 includes a pair of upper 11 and lower 15 panels connected together by a spine panel 13 to form a generally U-shaped frame structure. The traveler clip 10 is preferably formed of a hard plastic. Other suitable materials can be used such that the functionality of the traveler clip 10 is preserved. To achieve its first purpose, the traveler clip 10 includes an inclined dagger 12 that extends upward and backward from the lower panel 15 so that the upper end of the dagger 12 is positioned proximate the upper panel 11 with a small space retained between the upper panel 11 and ...

second embodiment

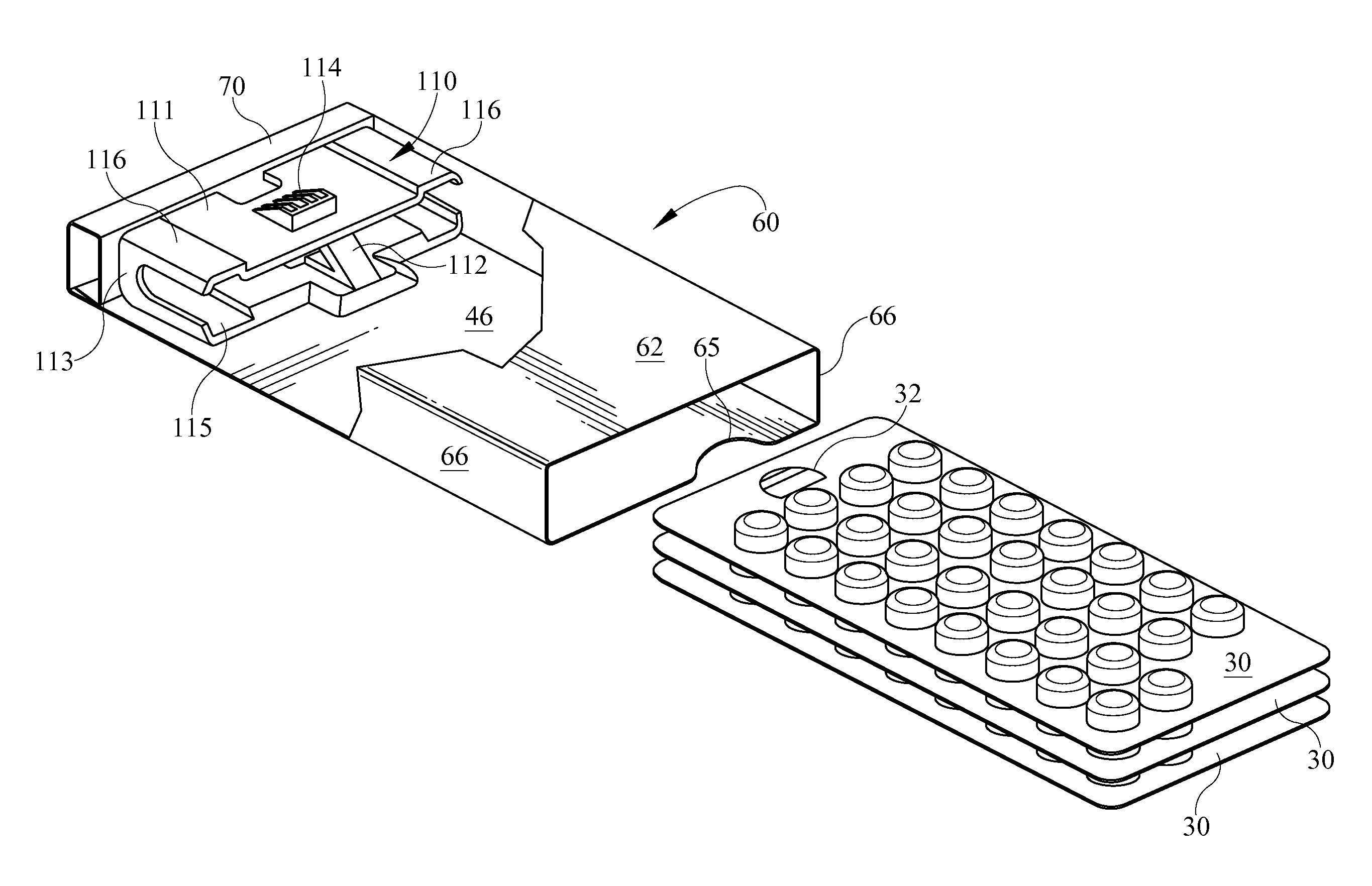

[0040]FIGS. 6-14 show the packaging apparatus according to the disclosure. In this embodiment, a traveler clip 110 (FIGS. 11-14) can be utilized with a paperboard sleeve in place of the hard plastic sleeve 10 described above. FIGS. 6-10 illustrate a blank 60 of a paperboard sleeve in various folded stages for assembling an erected sleeve (FIG. 10) adapted to receive the traveler clip 110. The folding process shown in FIGS. 6-10 progress from a completely flat, unfolded form (FIG. 6) of blank to a fully assembled three-dimensional form (FIG. 10) through intermediate forms (FIGS. 7-9) in which the blank 60 is partially folded and / or glued.

[0041]FIG. 6 illustrates the paperboard blank 60 in a completely flat form prior to any assembly. The paperboard blank 60 is comprised of a top panel 62 with an end panel 68 hingedly connected along a fold line 82, a first side panel 66 hingedly connected to the top panel 62 along a fold line 85, a bottom panel 64 with end stop panels 70 hingedly con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sliding movement | aaaaa | aaaaa |

| elevation | aaaaa | aaaaa |

| hard | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com