Truss spacer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

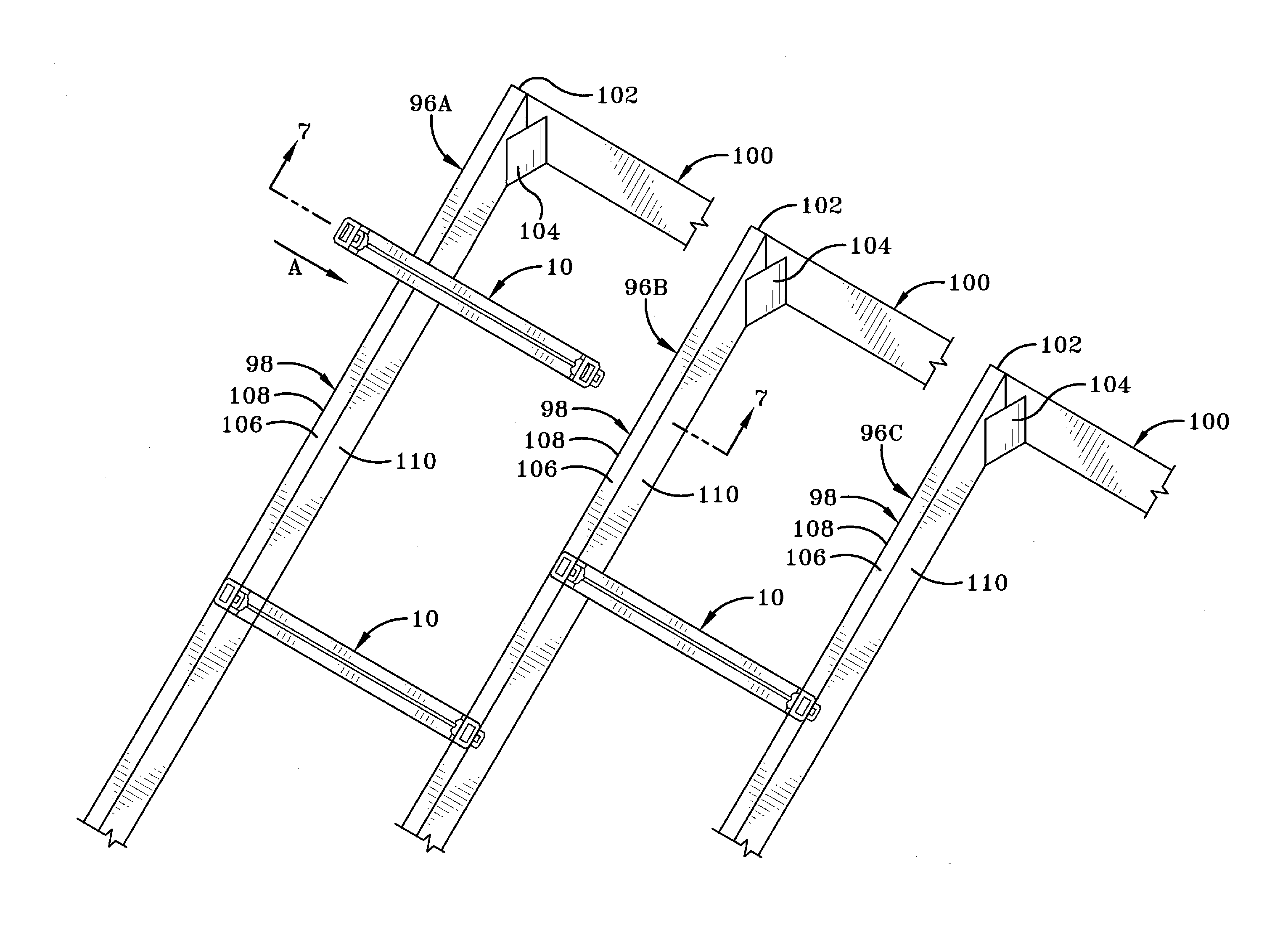

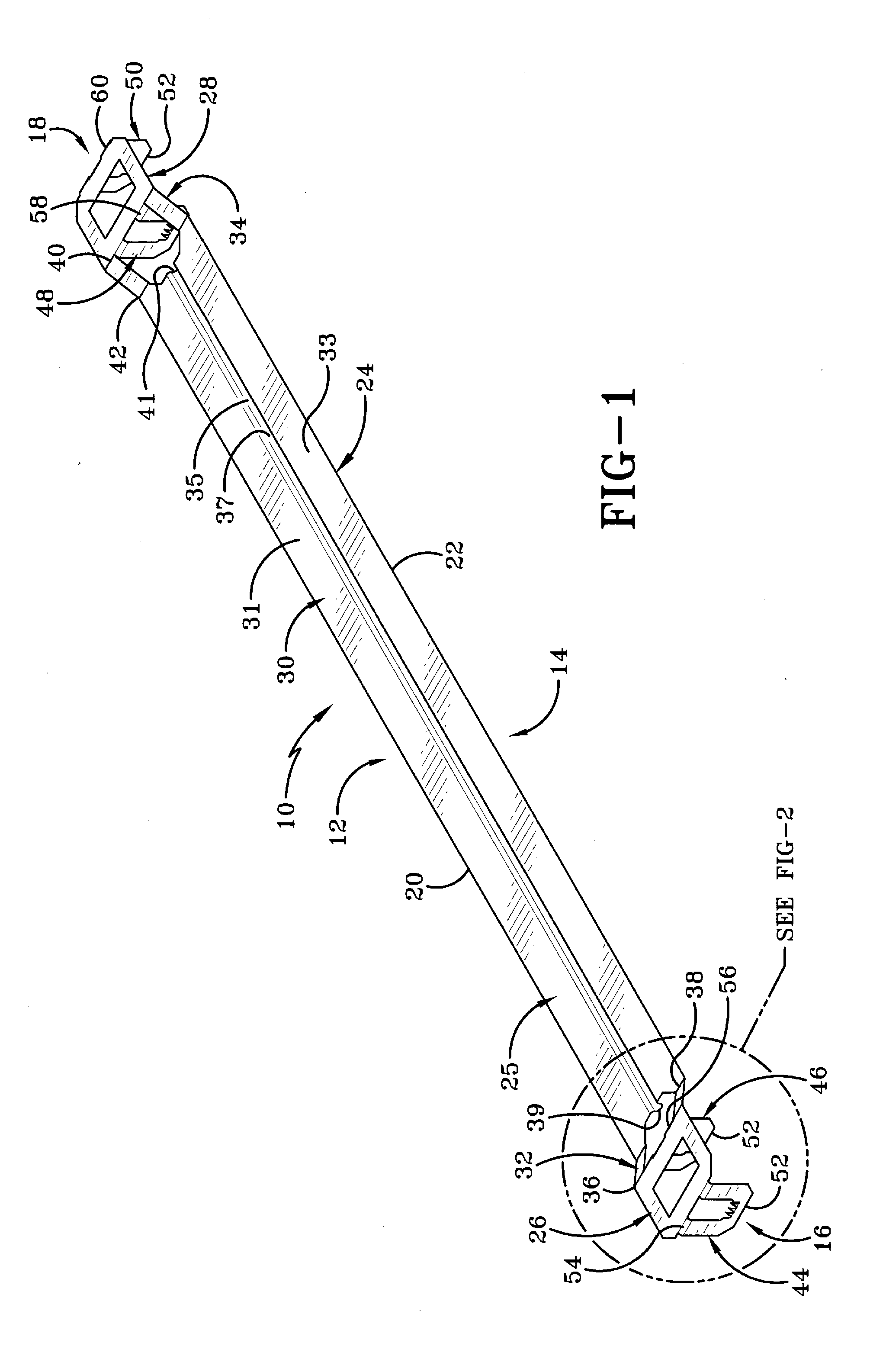

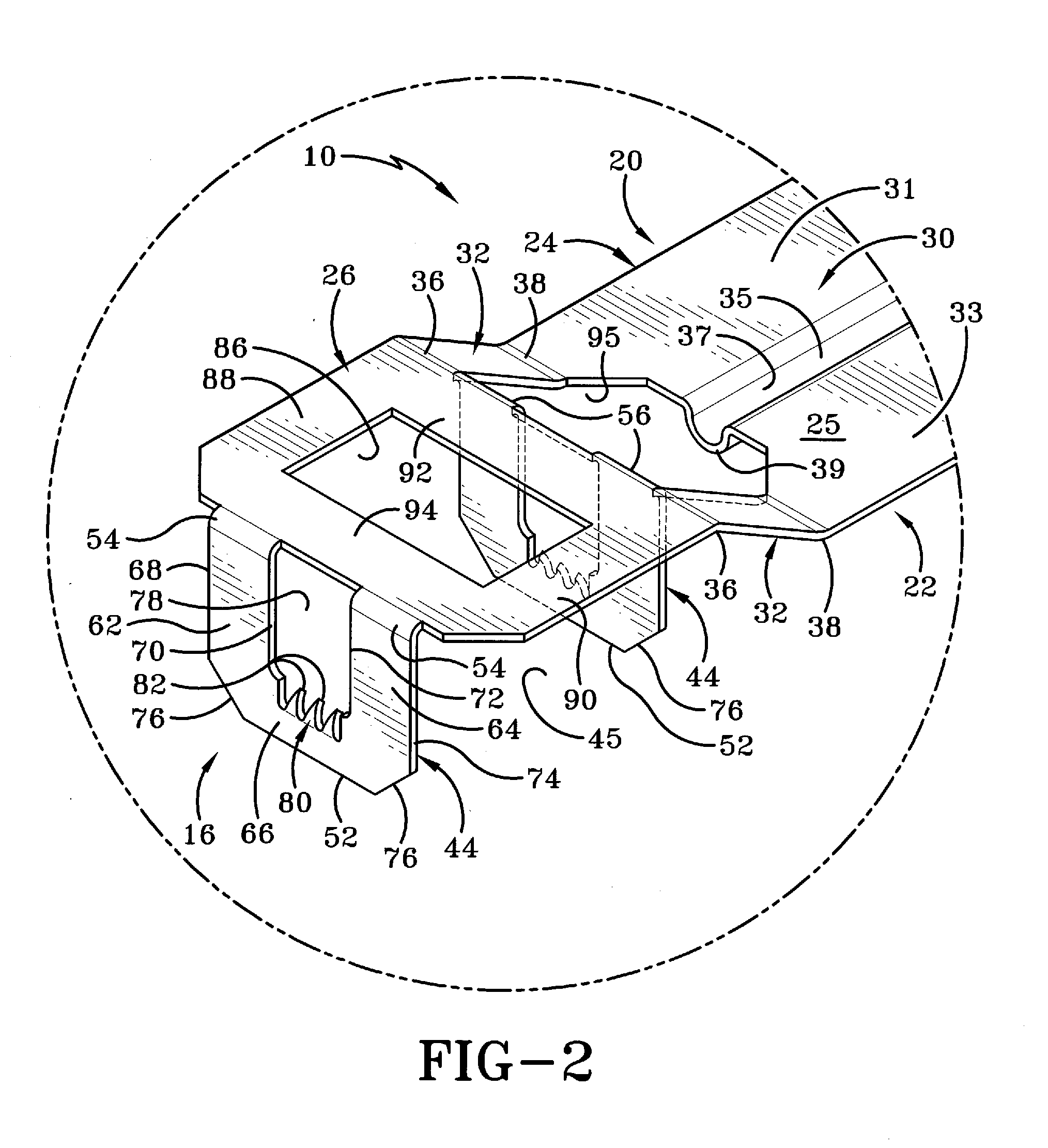

[0024]The truss spacer or spacer bar of the present invention is shown generally at 10 in FIG. 1. Spacer 10 is used to set the spacing between adjacent pairs of roof trusses during the building or installation of a roof, as will be described in greater detail further below. Spacer 10 is formed of a rigid material which is most typically metal. In the exemplary embodiment, spacer 10 in its entirety is formed from a single piece of sheet metal which is stamped and bent to form the various structures specified below. Spacer 10 is in the exemplary embodiment thus an integrally formed one-piece member. Spacer 10 has a top 12, a bottom 14, first and second opposed ends 16 and 18 defining therebetween a longitudinal direction of the spacer, and left and right sides 20 and 22 defining therebetween an axial direction of the spacer. Ends 16 and 18 define therebetween a length L1 which may vary depending on the specific spacer desired. In the exemplary embodiment, length L1 is on the order of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com