Resistive braking via screed heating

a technology of resistive braking and screed heating, which is applied in the direction of roads, roads, construction, etc., can solve the problems of reduced performance, reduced performance, and difficulty in meeting the minimum stopping time/maximum stopping distance requirements of tractor or other pulling machines coupled to multiple filled screeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

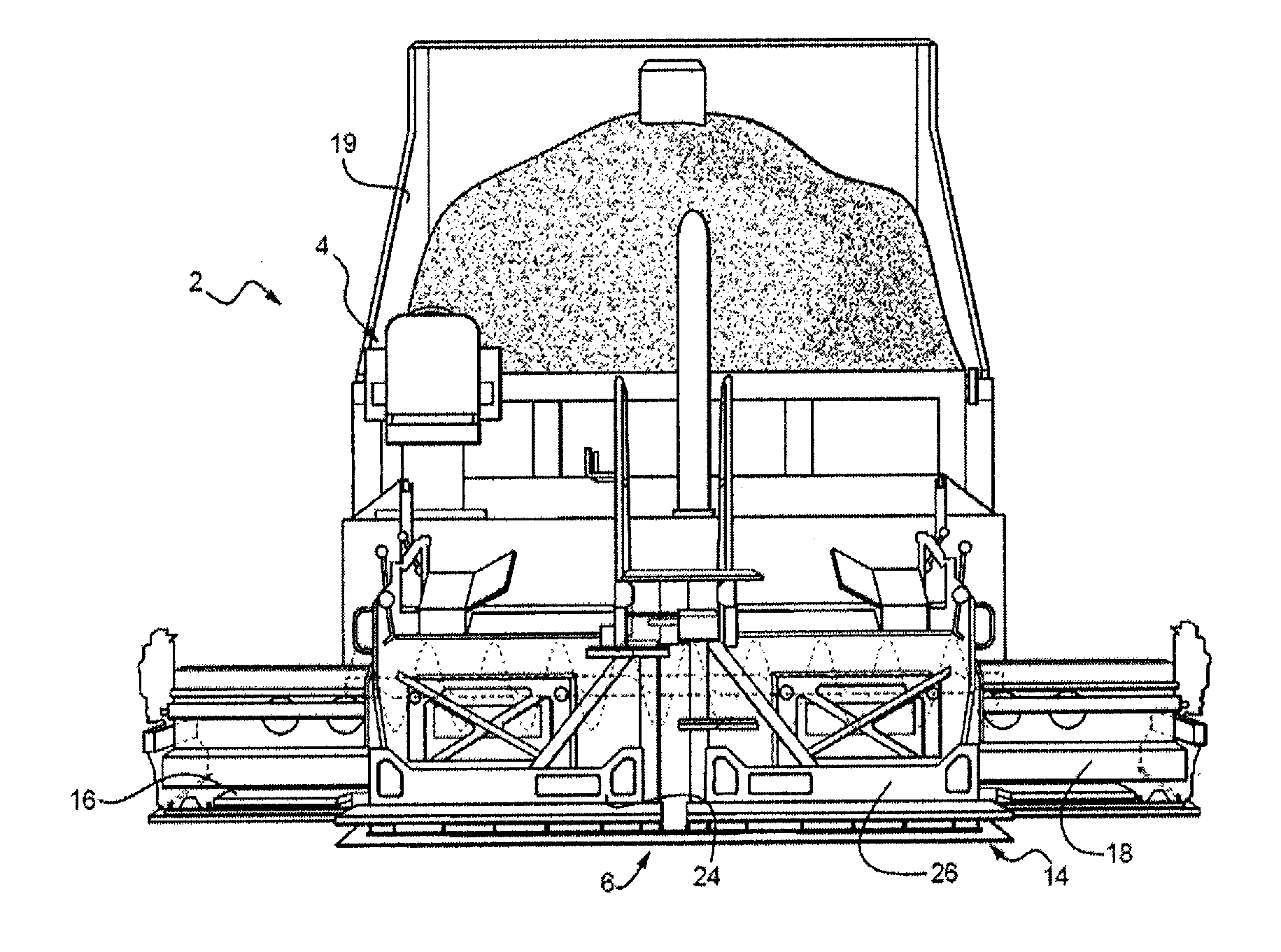

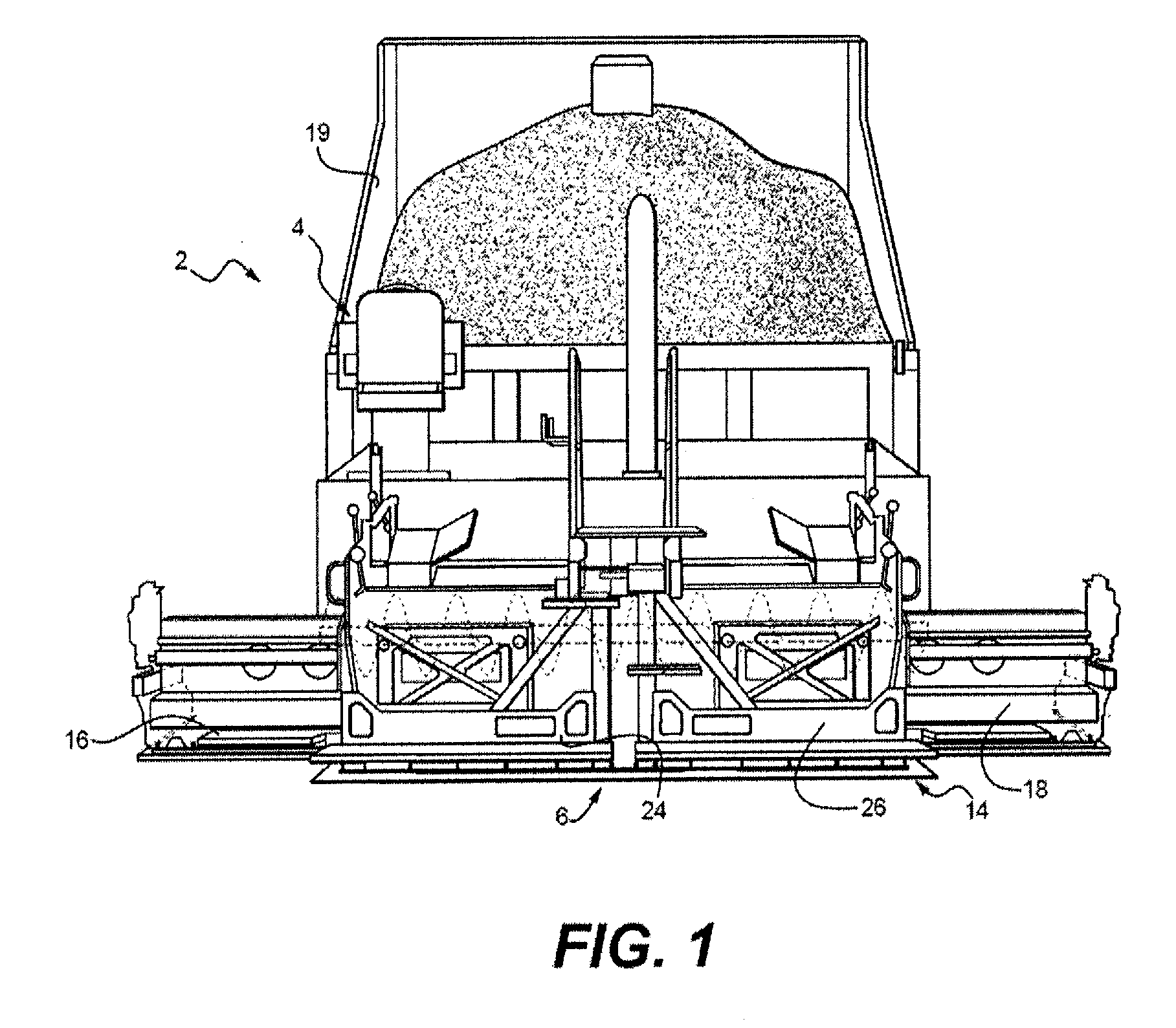

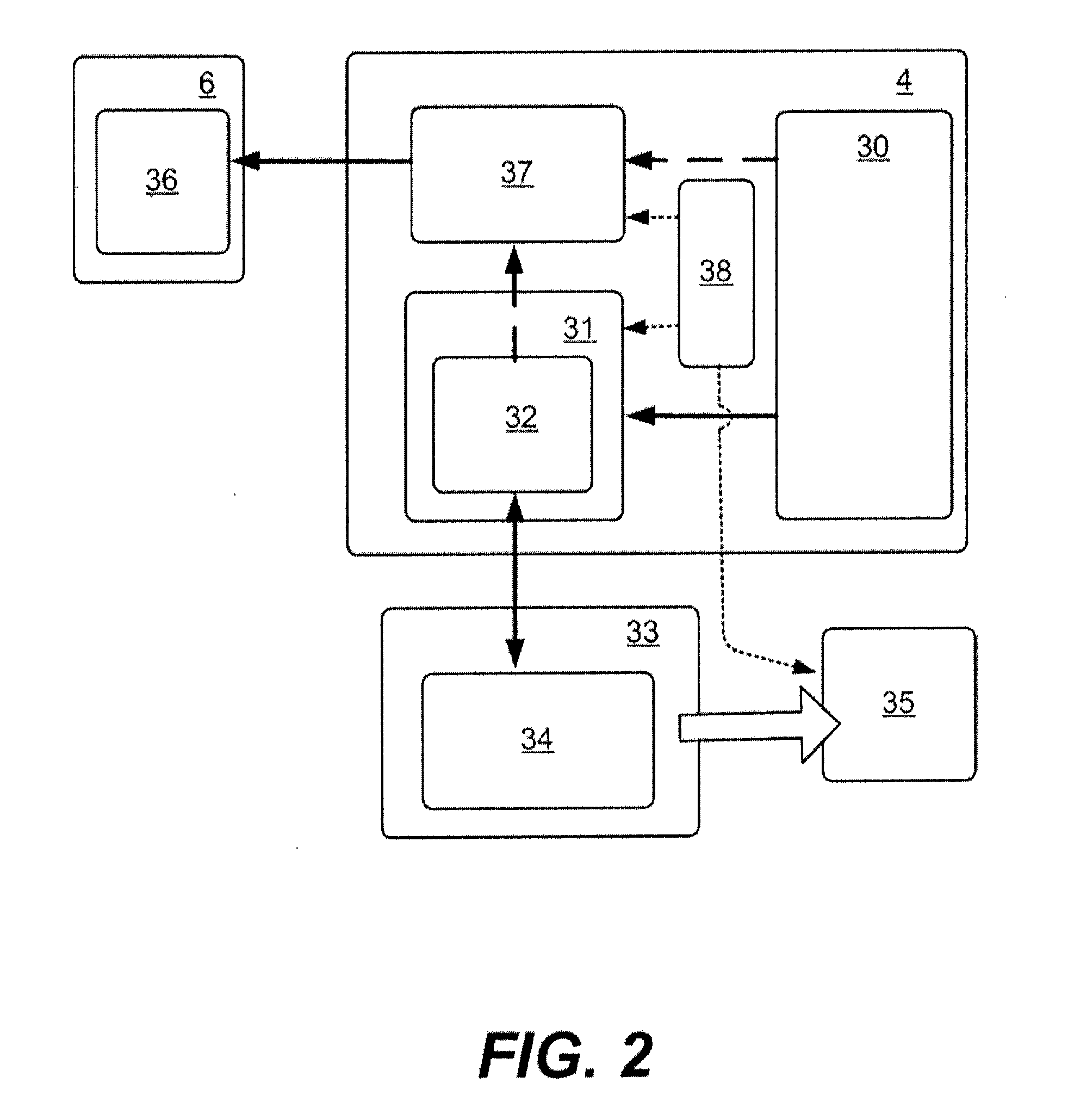

[0016]The present disclosure provides a system and method for the braking of paving machines via hydroelectric screed plate heating. Referring now to FIG. 1, an exemplary paving system 2 is schematically shown, in accordance with one or more embodiments of the present disclosure. It will be understood that only those components that are helpful for a proper understanding of the present disclosure are shown and / or described herein. Nevertheless, several other components that are commonly employed in combination or conjunction with such paving machines are contemplated and considered within the scope of the present disclosure.

[0017]In the illustrated embodiment, the paving system 2 includes a tractor 4 towing a screed assembly 6. The tractor 4 may include an engine, a transmission and wheels, tracks or other locomotive devices for moving the tractor 4 and coupled screed assembly 6. In an embodiment, the engine drives a hydraulic pump to generate pressurized hydraulic fluid used to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com