Teatcup liner

a tea cup and liner technology, applied in the field of tea cup liner, can solve the problem that teats are not capable of being deformed, and achieve the effect of gentle teat treatment and efficient milking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

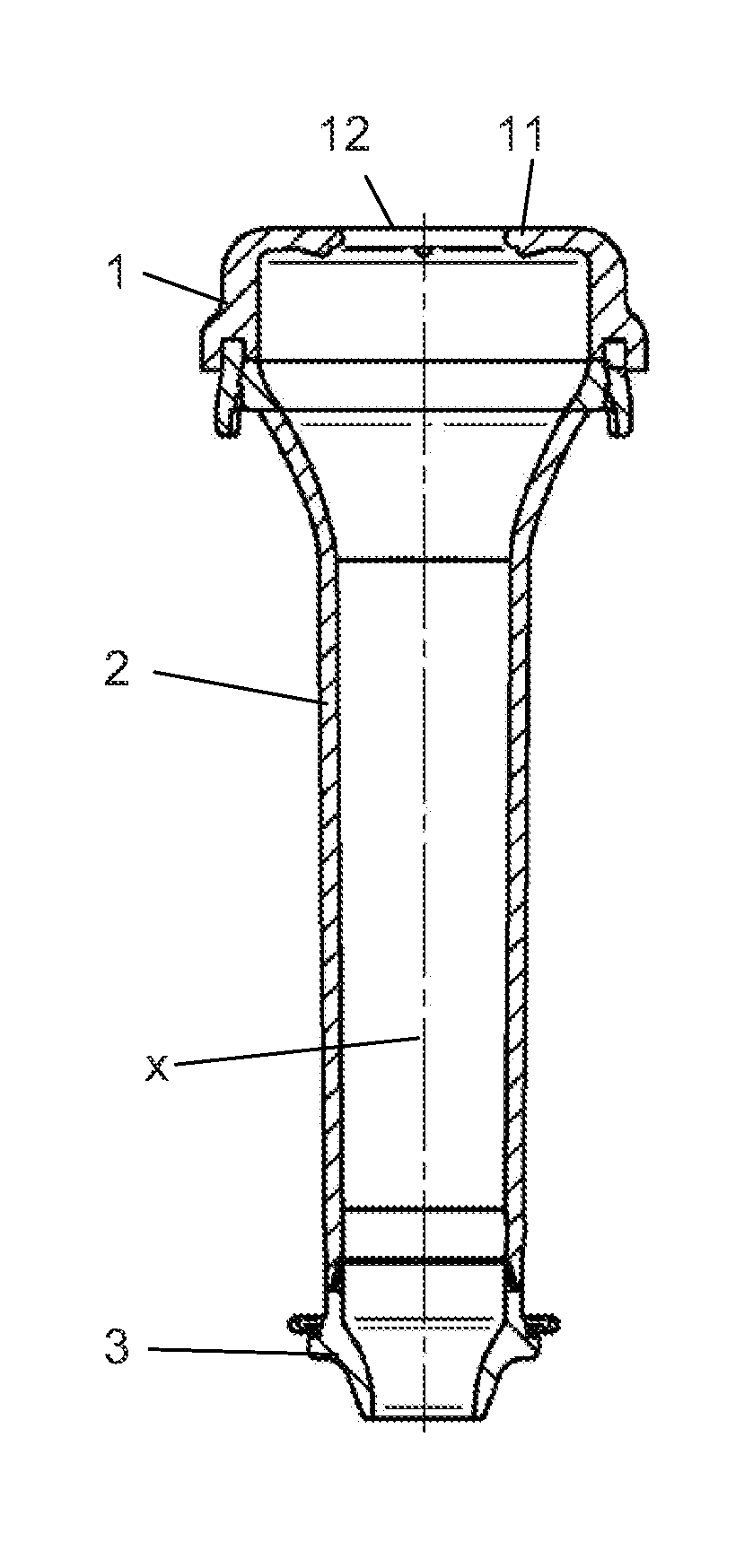

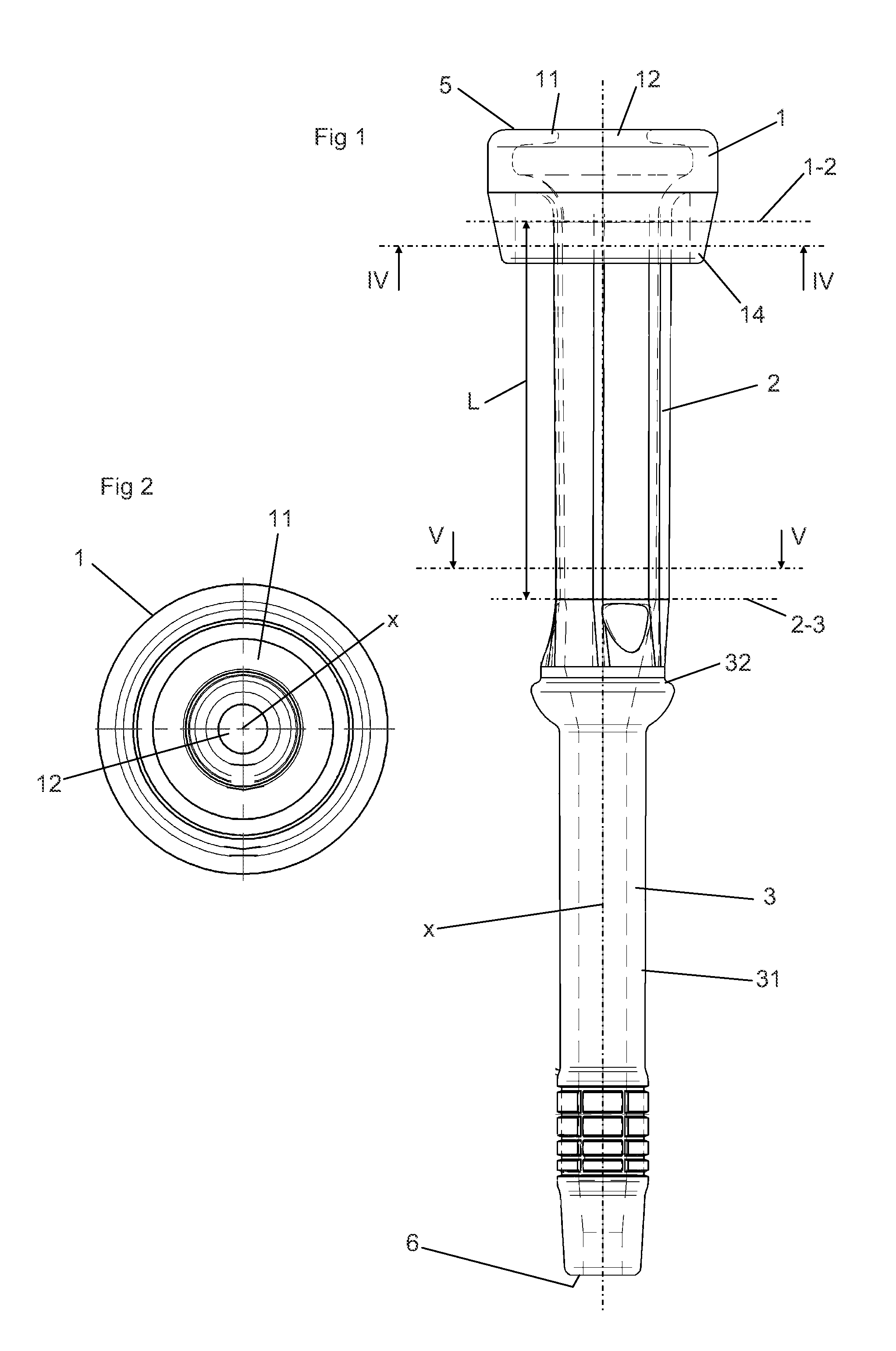

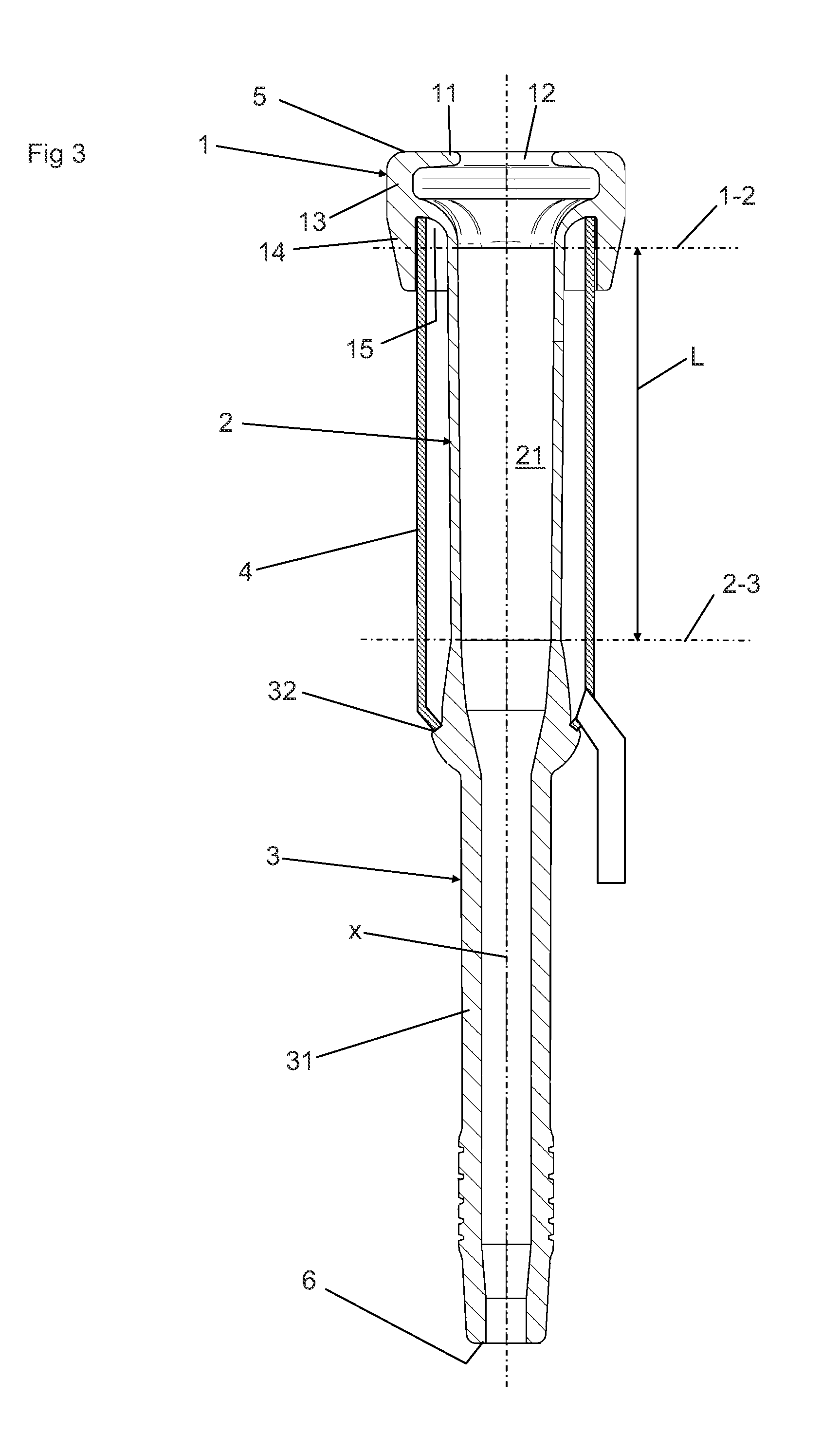

[0040]FIGS. 1 and 2 disclose a teatcup liner comprising a head 1, a barrel 2 and an outlet portion 3. As can be seen in FIG. 3, the teatcup liner is configured to be mounted in a shell 4 of a teatcup, i.e. the teacup liner and the shell 4 may form the teatcup, to be applied to a teat of an animal.

[0041]The teatcup liner has a longitudinal shape and extends along a longitudinal axis x. The head 1, the barrel 2 and the outlet portion 3 are provided subsequently after each other along the longitudinal axis x. In the first and second embodiments, the head 1, the barrel 2 and the outlet end 3 are manufactured in one piece of one elastomeric material, such as natural or synthetic rubber, thermo-plastic elastomers, etc. It is to be noted that the head 1 and / or the outlet portion 3 may be manufactured in another, possibly less elastomeric material than the barrel 2.

[0042]The border between the head 1 and the barrel 2 is indicated by the line 1-2 in FIGS. 1 and 2. The border between the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com