Sectionalized arrow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

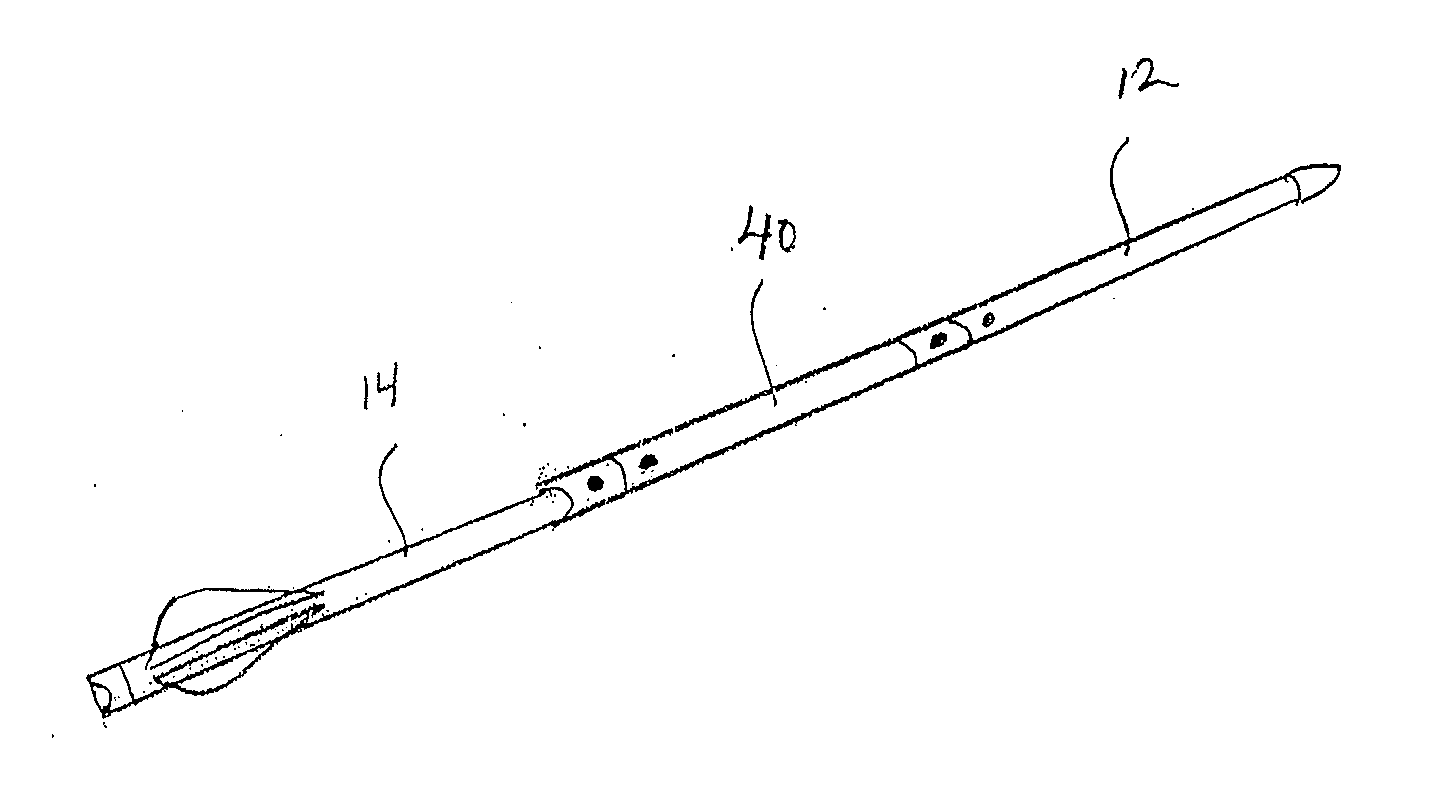

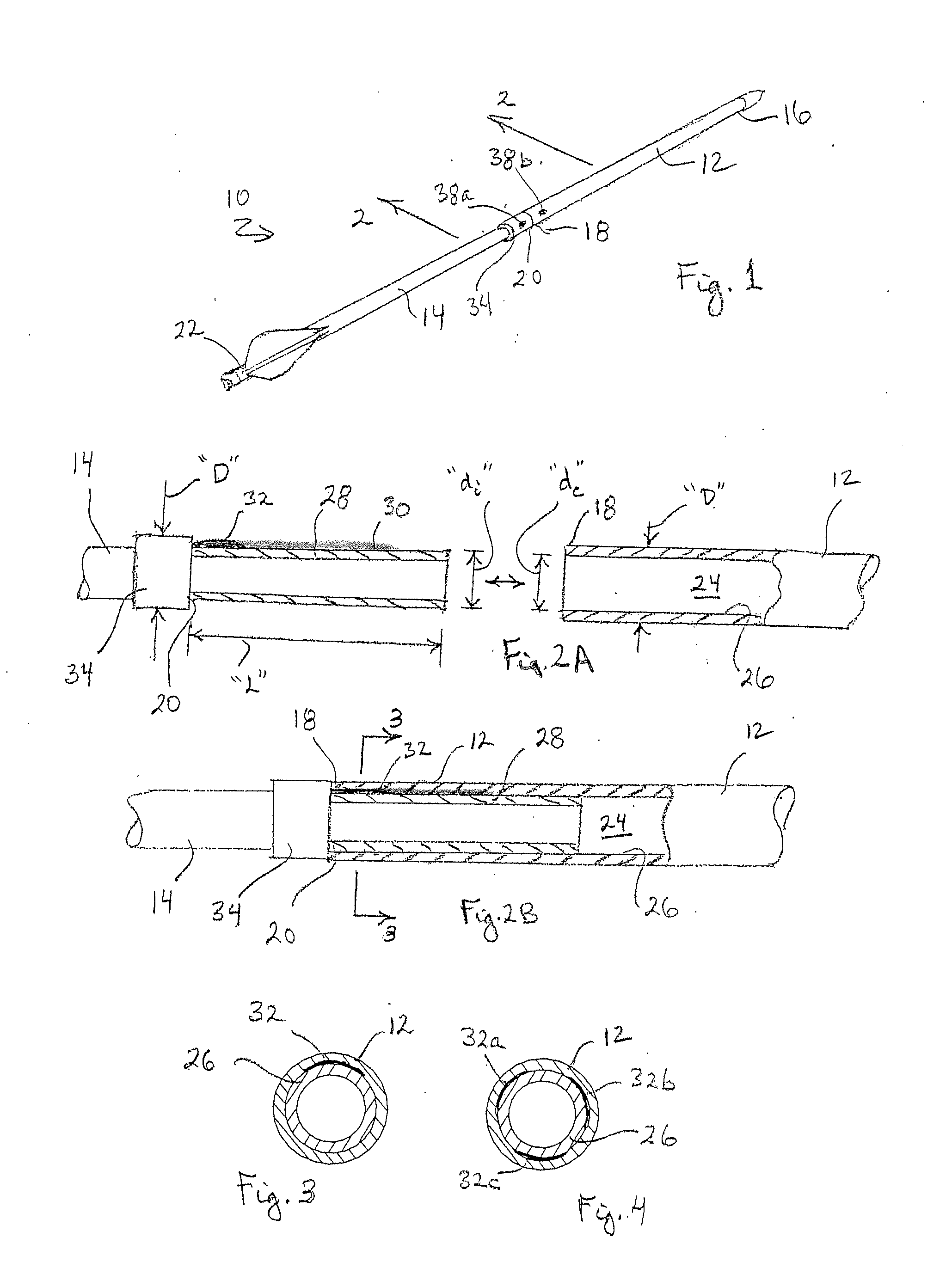

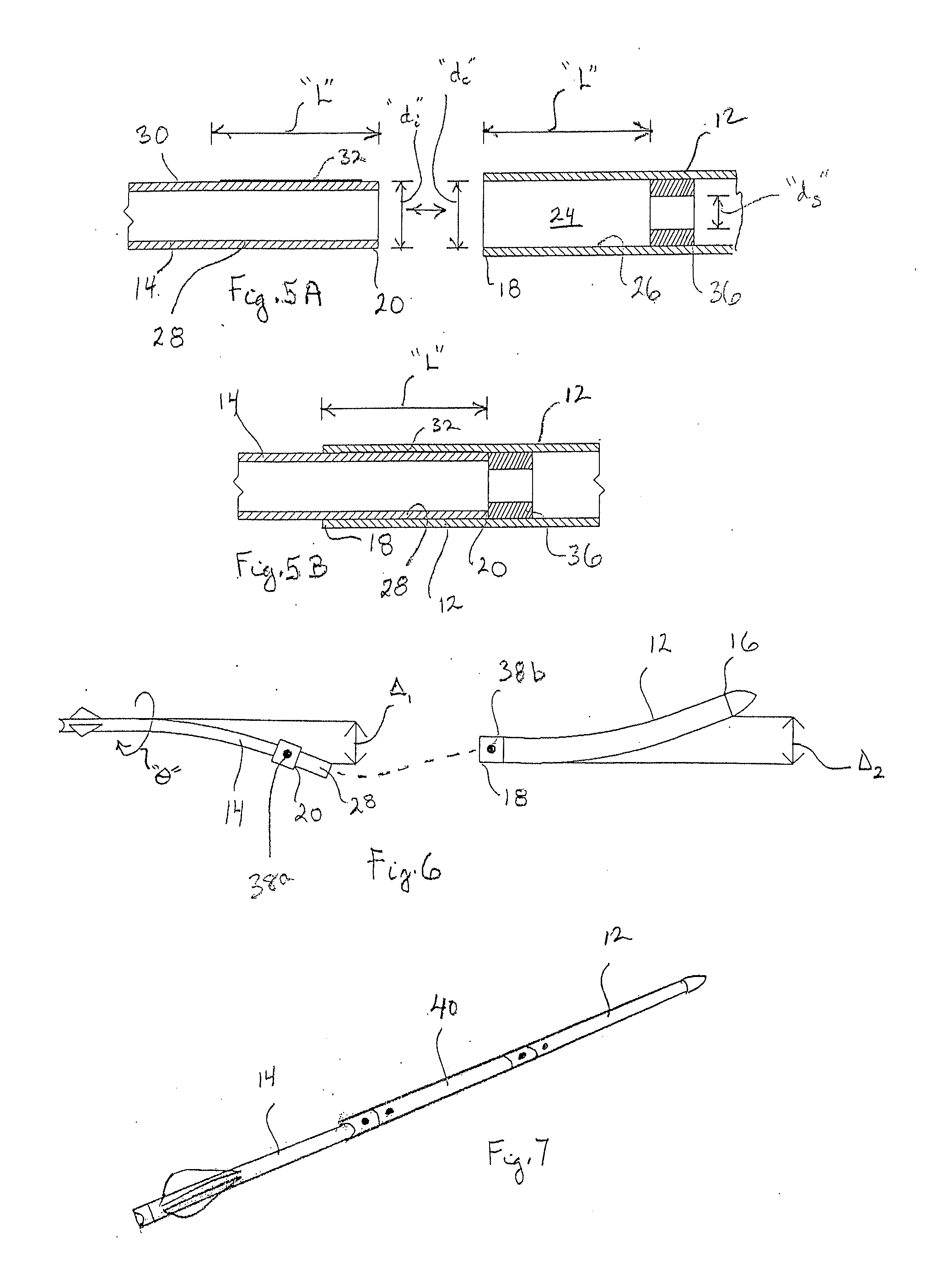

[0023]Referring initially to FIG. 1, a sectionalized arrow in accordance with the present invention is shown and is generally designated 10. As shown, the arrow 10 includes a tip section 12 and a nock section 14. Further, the tip section 12 has a fore-end 16 and an aft-end 18. Similarly, the nock section 14 has a fore-end 20 and an aft-end 22.

[0024]In FIG. 2A it will be seen that the tip section 12 is essentially a hollow, tubular-shaped structure that is formed with a chamber 24 inside the aft-end 18 of the tip section 12. Further, the tip section 12 is shown to have an outer diameter “D”, and the chamber 24 is shown to have a diameter “dc”. Similarly, it will be seen in FIG. 2A that, like the tip section 12, the nock section 14 is also essentially a hollow, tubular-shaped structure. The nock section 14, however, is formed with an insert 28 that extends axially from the fore-end 20 of the nock section 14. As shown, the insert 28 has a length “L” and it has an outer surface 30 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com