Base and spool for managing hose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

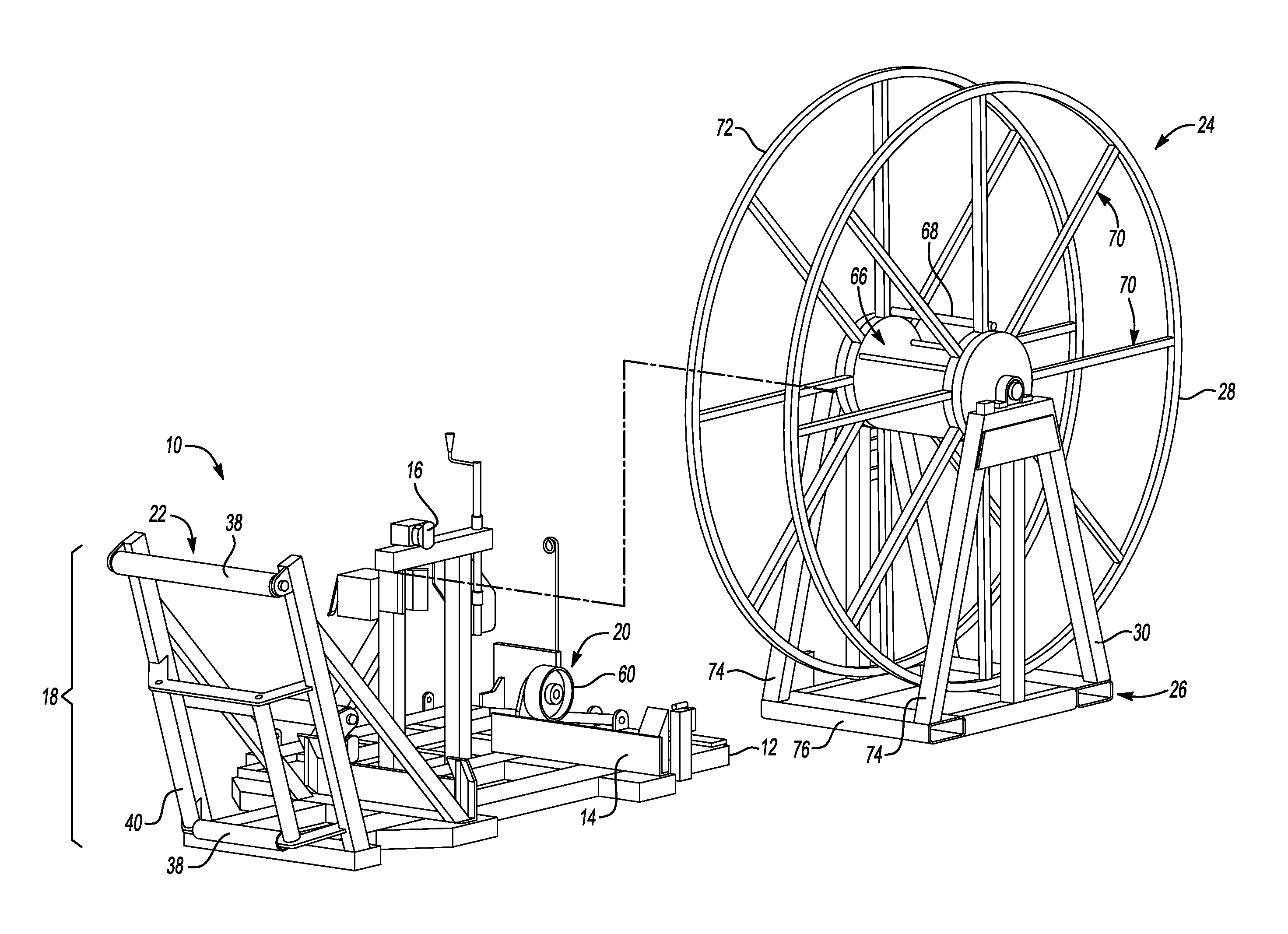

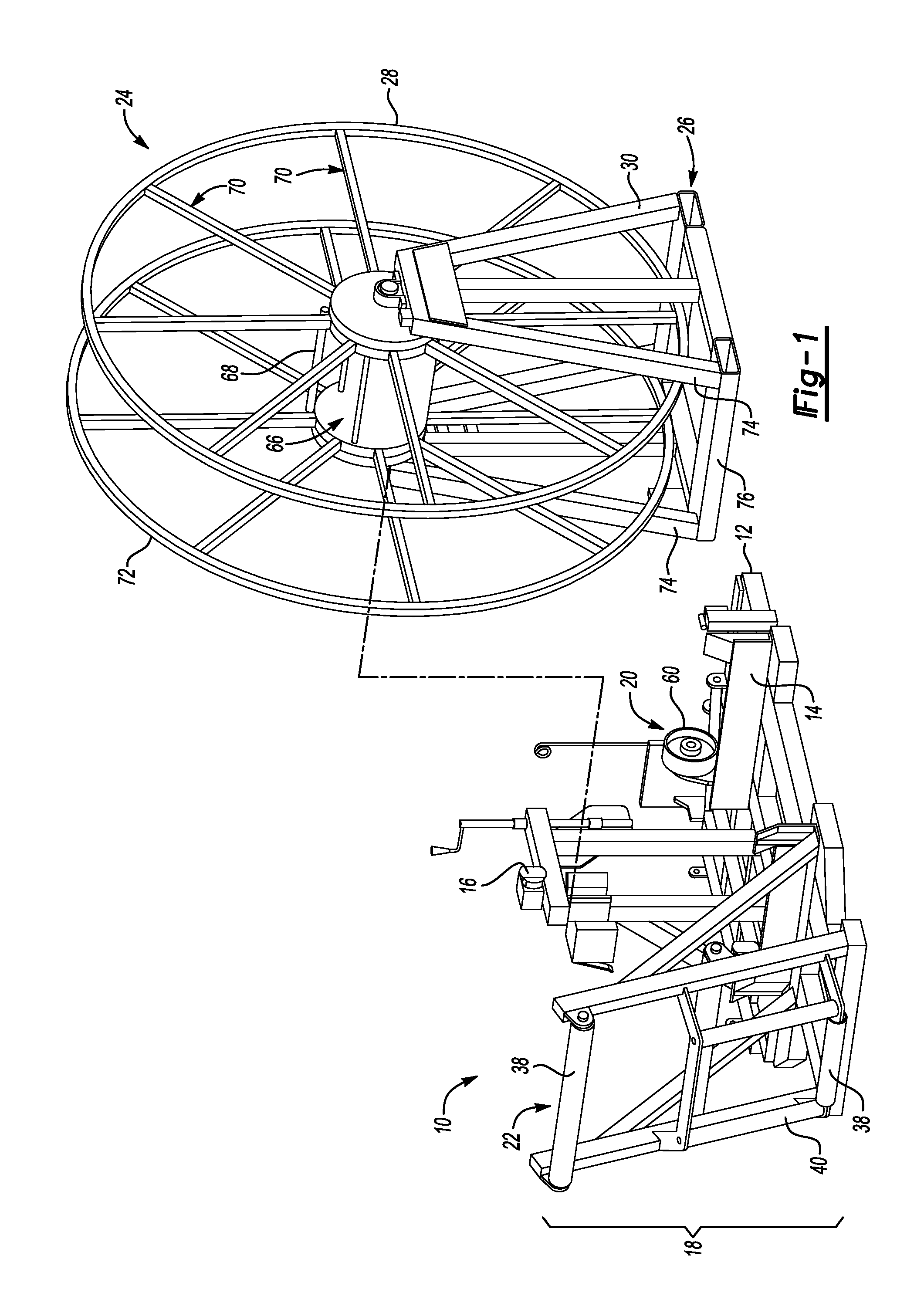

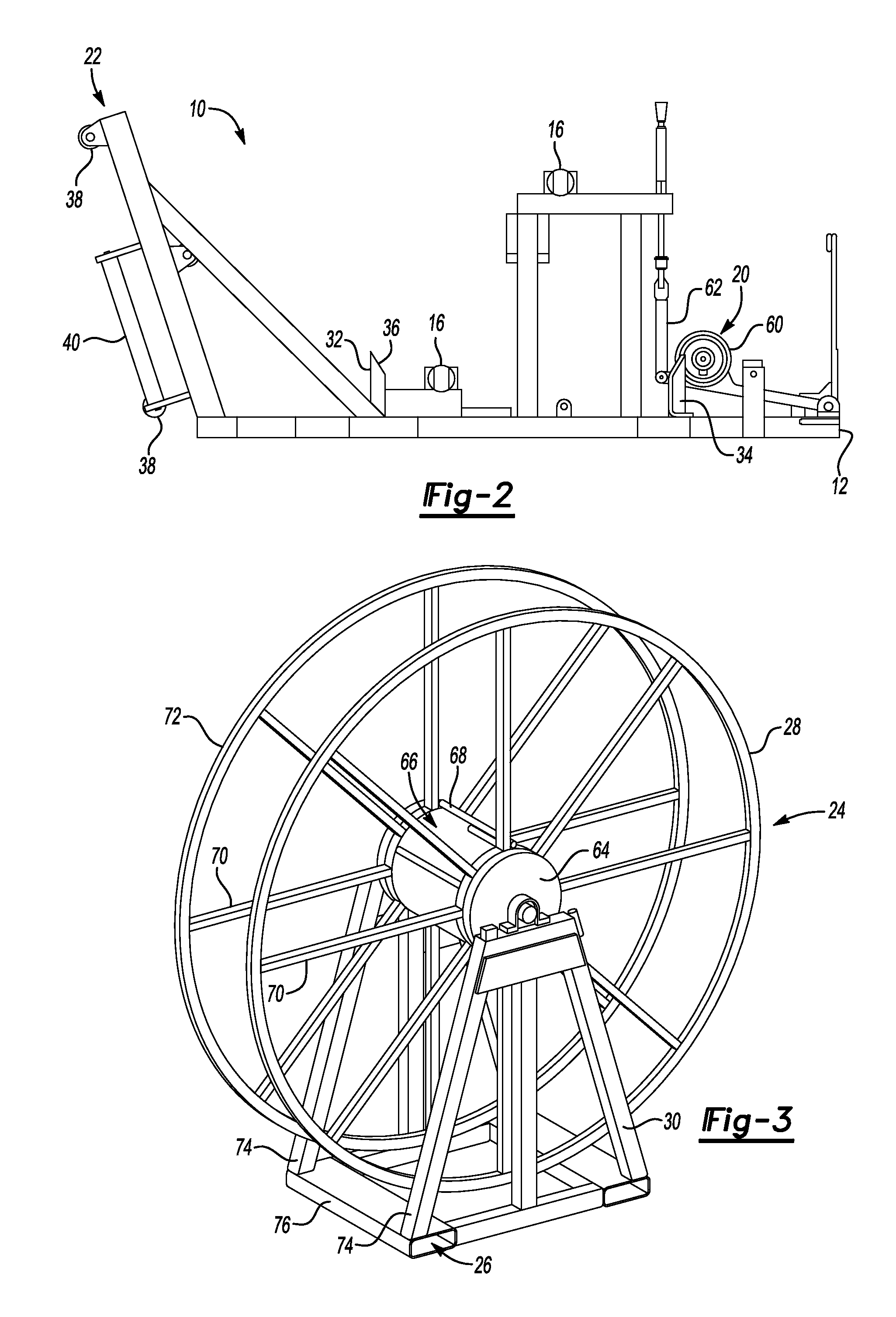

[0024]The present invention comprises devices, systems, and methods for managing, storing, deploying or retrieving hose, preferably lay-flat hose. In one embodiment, the hose management system comprises a base and a spool. The base serves to support and to hold the other components the hose management system, while the spool serves to maintain the lay-flat hose during storage, deployment or retrieval.

[0025]As seen in FIGS. 1 and 2, the base 10 is typically made of metal, such as steel and has sufficient strength to support the weight of a loaded spool; that is, a spool with a hose loaded onto it. The base comprises several different components which have different functions. For example, the base may include at least one lift point 12, a reel frame guide 14 and at least one reel lockdown 16. The base may also include a hose guide assembly 18 and a drive wheel assembly 20. The hose guide assembly may include a level wind device and a hose tensioning device 22, while the drive wheel a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap