Exhaust gas sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

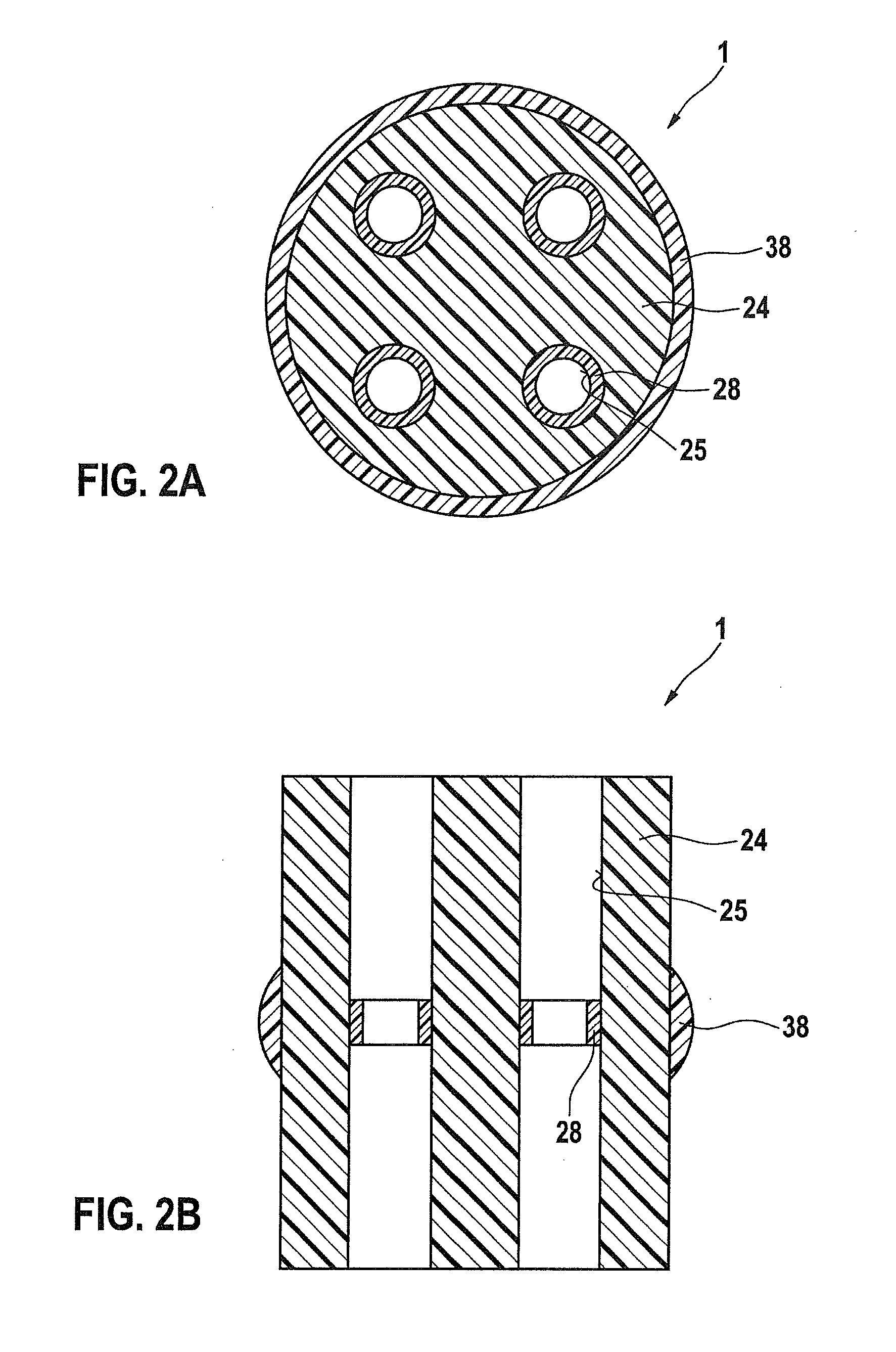

[0062]The second exemplary embodiment differs from the first exemplary embodiment in that seal 26 is configured not as a layer on the inner contour of base body 24 over the entire surface, but, rather, as a sealing ring 28 which is situated on the inner contour of the base body and which only partially covers same in the longitudinal extension. Sealing ring 28 has a length (in the longitudinal direction of through channel 25) of 1 mm and a thickness (in the radial direction) of 150 μm or 250 μm.

[0063]Furthermore, the second exemplary embodiment differs from the first exemplary embodiment in that outer seal 36 is configured not as a radially outer layer over the entire surface of base body 24, but, rather, as an outer sealing ring 38 which is radially outwardly situated on base body 24 and which only partially covers the outer surface of base body 24 in the longitudinal extension. Outer sealing ring 38 has a length (in the longitudinal direction of base body 24) of 3 mm and a thickne...

Example

[0072]In contrast to the third exemplary embodiment, it is provided that insulation 19 of connecting cable 21 and seal 26 are not configured as parts which are different from one another; instead, seal 26 at the same time takes on the function of insulation 19 of electrical conductor 20, and faces same, in particular directly. In the present example, seal 26 and insulation 19 together with electrical conductor 20 are led out of stopper 1 in particular on two sides or on one side, and insulate electrical conductor 20 of connecting cable 21 also outside of stopper 1, for example up to a portion of a plug-in connection (not shown), for example a plug, which is connected to connecting cable 21 on the side of connecting cable 21 opposite from stopper 1, and which is connectable to, in particular pluggable into, a complementary part of the plug-in connection, a socket, for example, which is part of a control unit.

[0073]In the present example, insulation 19, which at the same time forms in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap