Safety Rail

a safety rail and rail technology, applied in the field of safety rail, can solve the problems of increasing transportation cost and increasing manufacture cost, and achieve the effect of reducing replacement cost and lowering manufacture cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

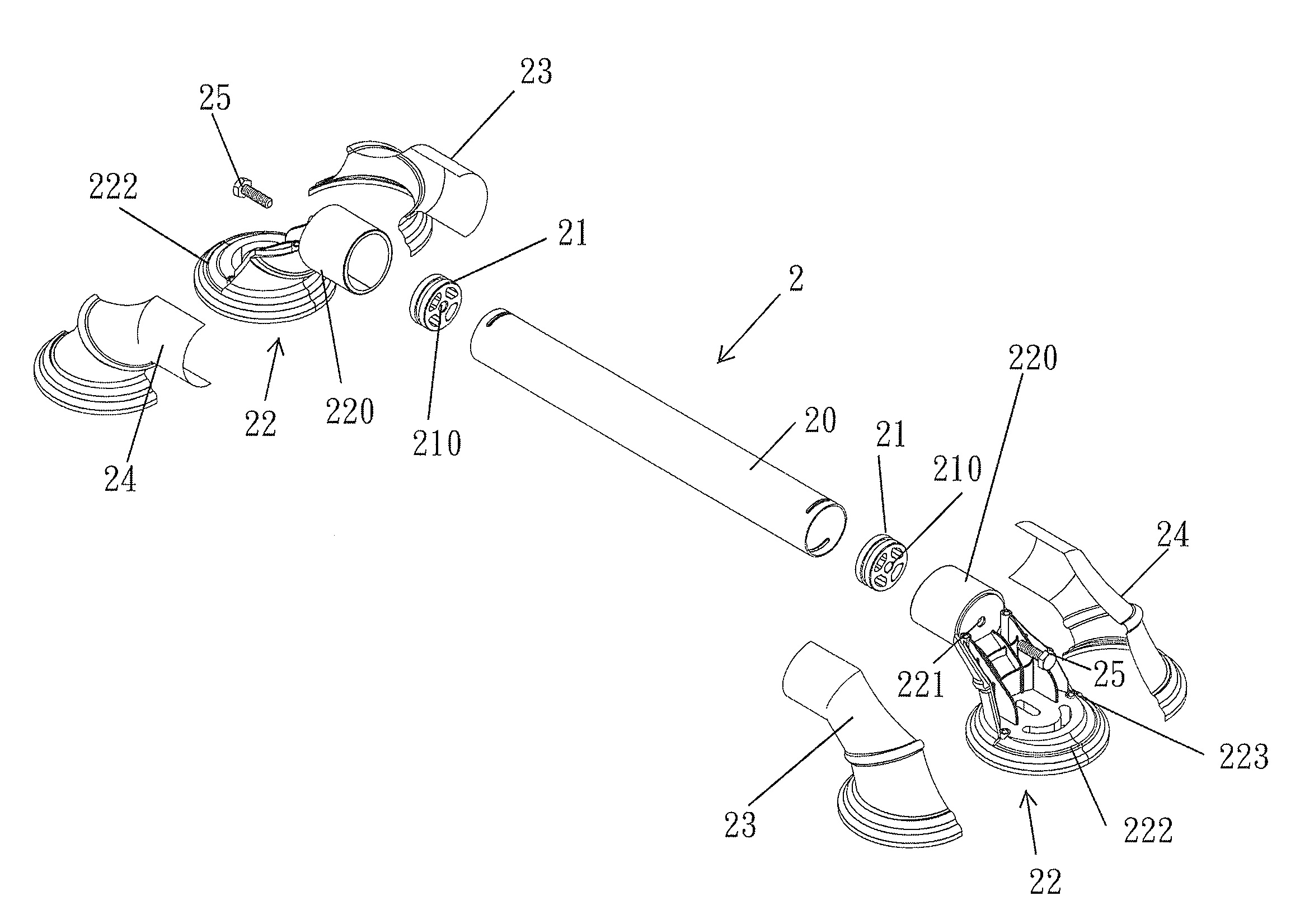

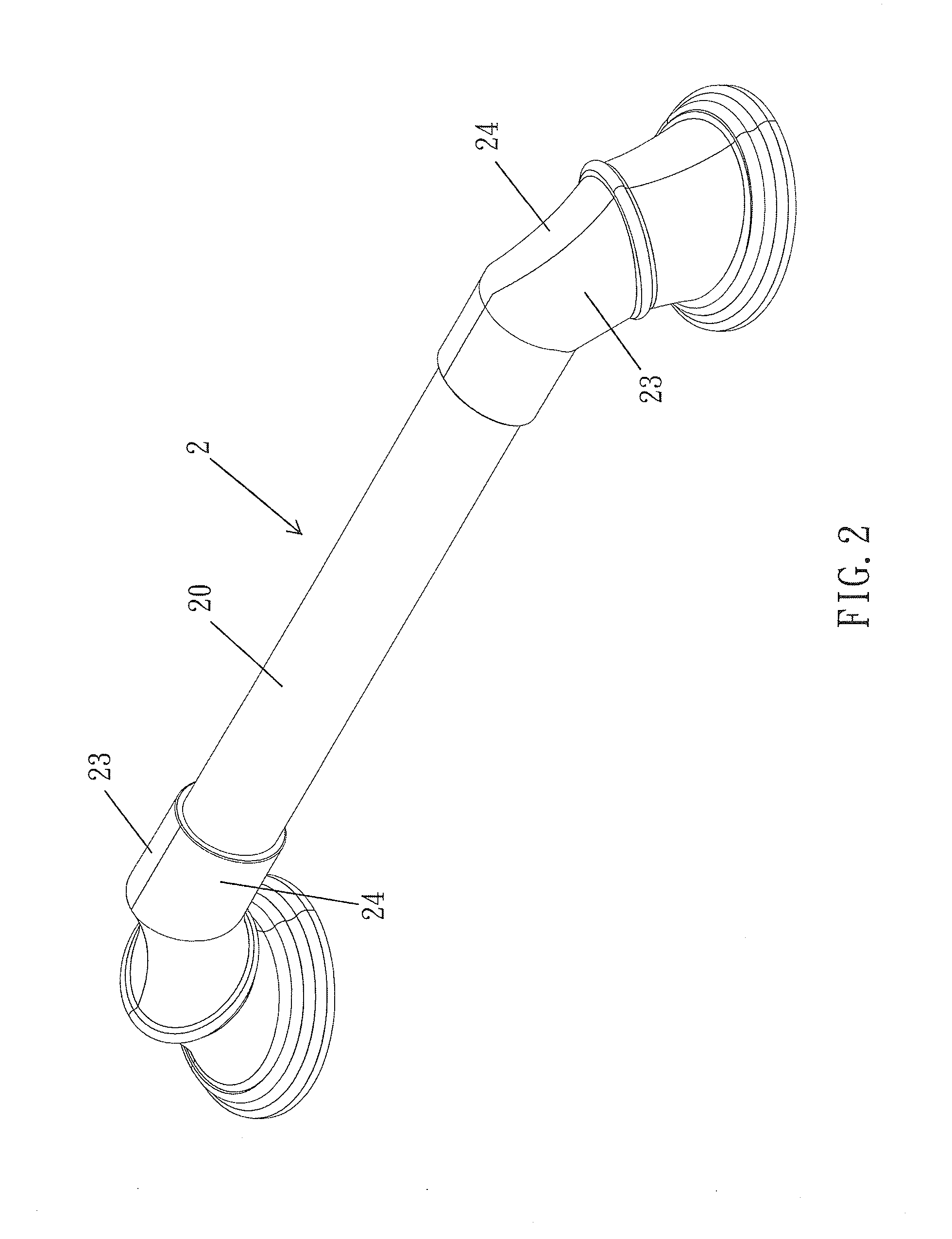

[0016]With reference to FIGS. 2-4, a safety rail 2 according to the present invention comprises: a tube 20, two connecters 21, two fixing holders 22, two first covers 23, two second covers 24, and two screwing elements 25. Each connector 21 includes an orifice 210 defined on a central position thereof so as to screw with each of the two screwing elements 25. Each fixing holder 22 is one piece formed and includes a fitting member 220 disposed on a first end thereof so as to fit with the tube 20, the fitting member 220 has a hole 221 formed on a central position thereof so as to insert each of the two screwing elements 25, each fixing holder 22 also includes a circular disc 222 mounted on a second end thereof so as to couple with a wall surface and an aperture 223 arranged on a predetermined position thereof. Each first cover 23 and each cover 24 are employed to cover each fixing holder 22. In assembly, the two connecters 21 are connected on two ends of the tube 20, the two fixing hol...

second embodiment

[0017]As shown in FIGS. 5-7, each of two casings 26 of the present invention is applied to replace a respective one of the two first covers 23 and a respective one of the two second covers 24 so that each casing 26 is covered on each fixing holder 22 after each fixing holder 22 and the tube 20 are coupled together, thus assembling the safety rail 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com