Frame hanging wire post with locking connector

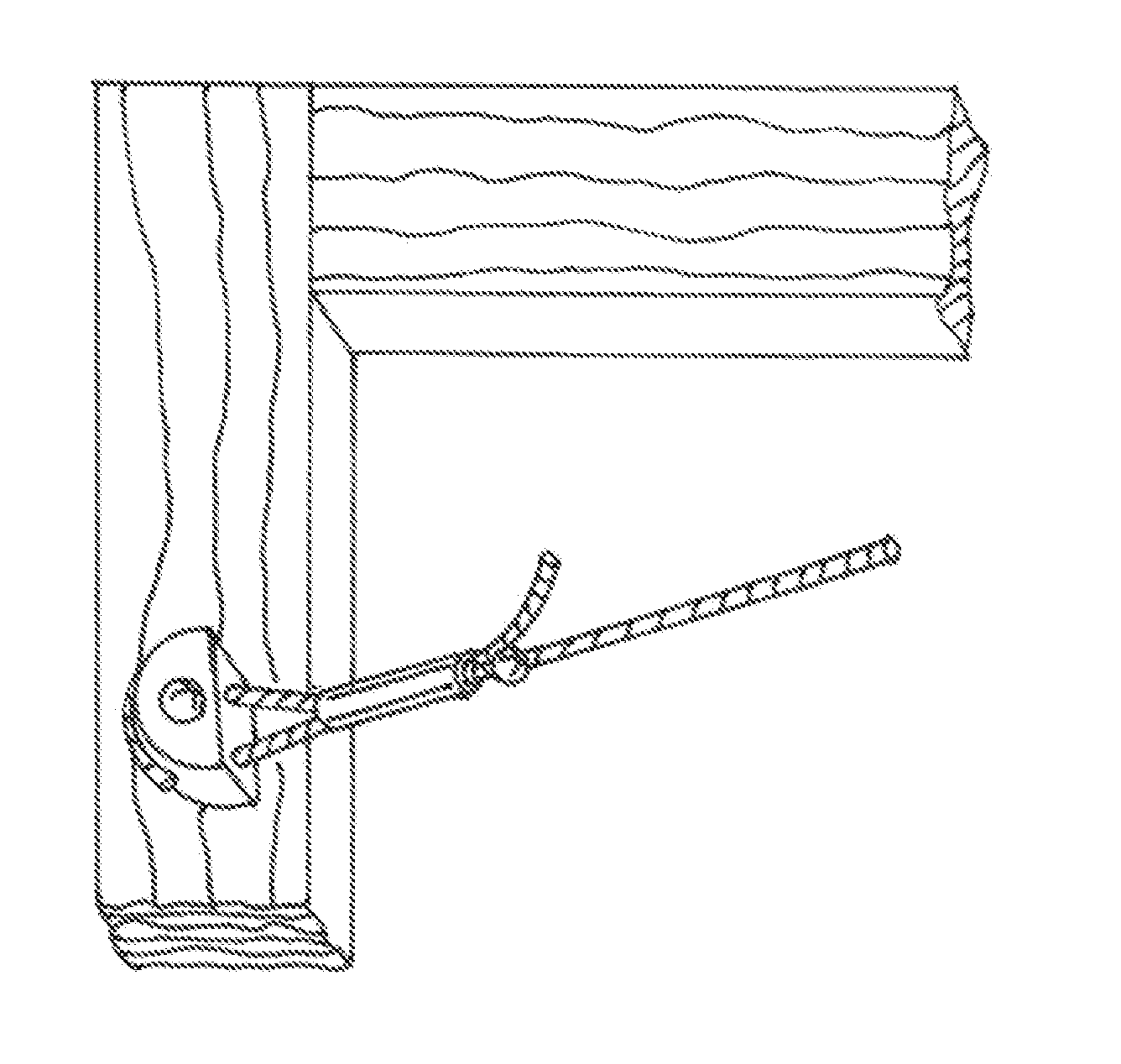

a technology of locking connector and hanging wire, which is applied in the direction of machine supports, other domestic objects, mechanical apparatus, etc., can solve the problems of stiff stranded wires that do not lend themselves, the eyelet is relatively weak, and is subject to bending and/or dislodging from the picture frame, etc., to facilitate connecting and adjusting lengths, facilitate threading, and facilitate the effect of attachment to the fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

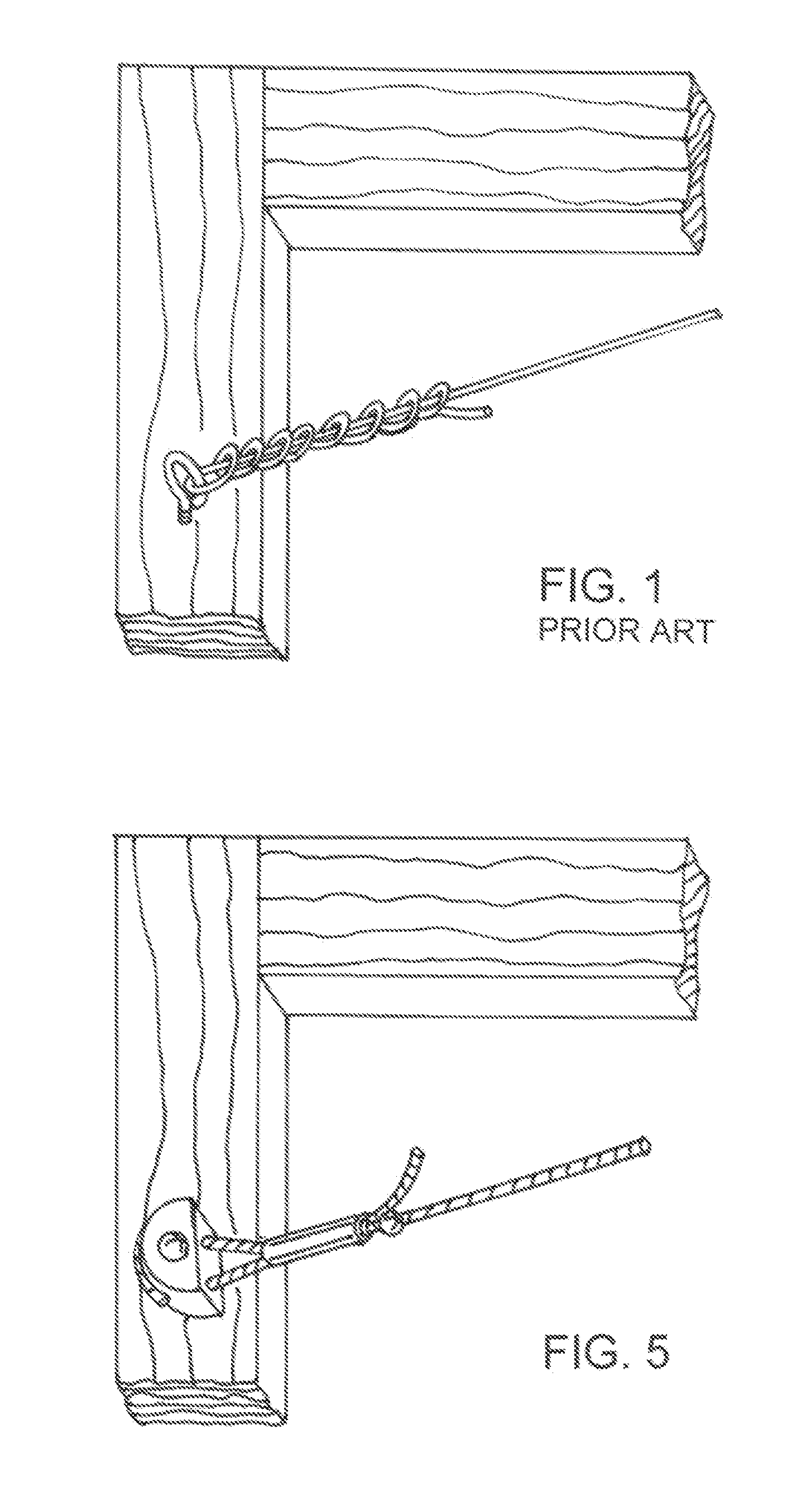

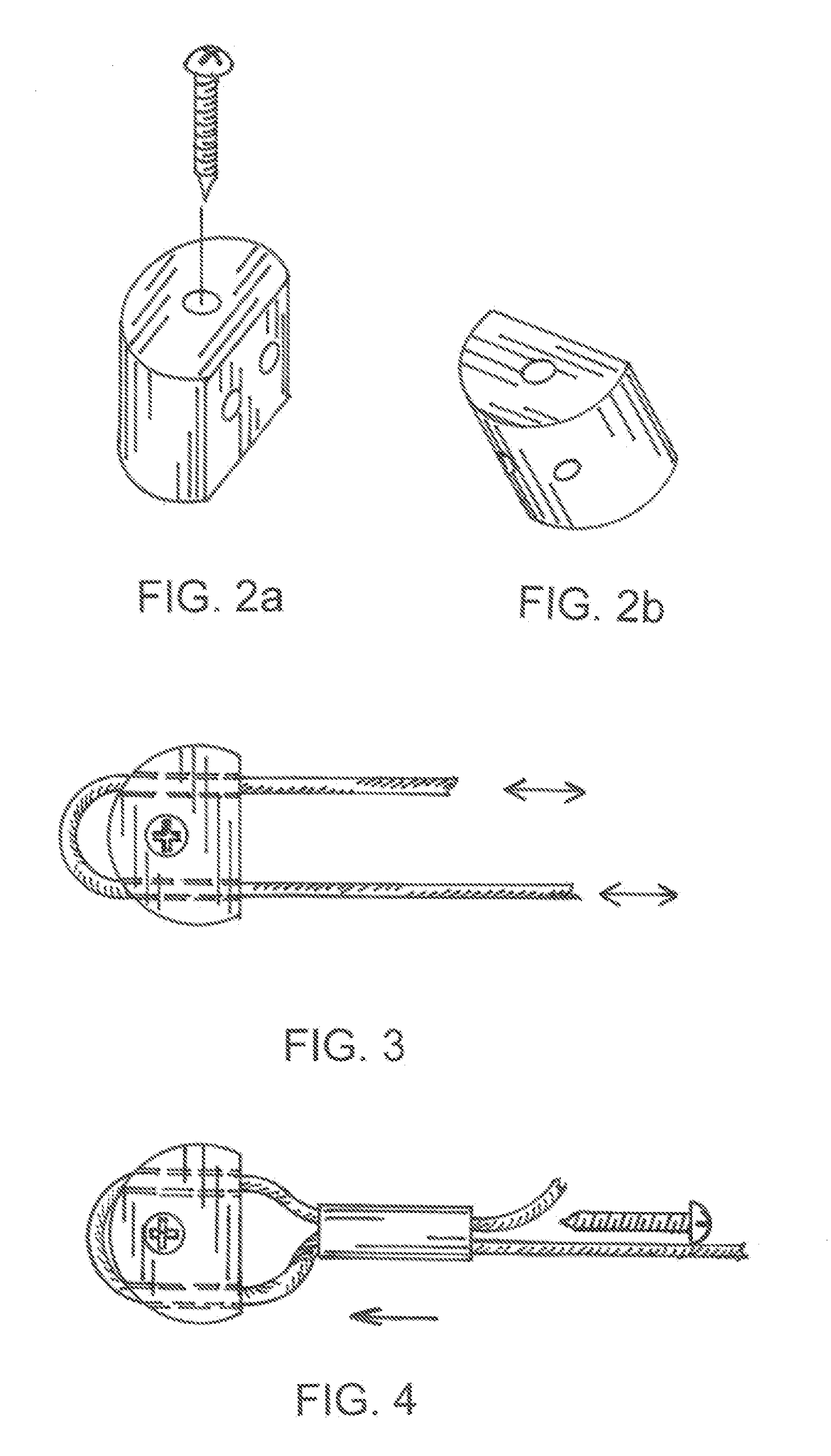

Embodiment Construction

[0011]This basic hitching post is a short length (.60″ typ) of a circular / semicircular rod section with a center point bore (.160″ ID typical) that will accept the attach screw to attach this post section to frame. This post section will typically have parallel bore holes that allow the hanging wire to be threaded through, looped around back side of circular section of post, and threaded back through second bore hole with enough extra length to allow for installation of the parallel line splice connector. Ideally the component materials for completing an installation would be supplied as a kit; containing the particular strength-rated hanging wire and the corresponding hitch posts with locking connectors. The bore hole diameters for posts would typically be about 1.2 times the actual wire OD. The centerline spacing between the parallel boreholes would be about 4.2 times the wire OD. Typically the diameter of post would be .50 inch for wire up to .050″OD, and .75 inch for wires up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com