Laundry treating appliance with bulk dispenser and treating chemistry cartridge therefor

a technology of a dispenser and a laundry machine, which is applied in the field of laundry treatment appliances with bulk dispensers and treating chemistry cartridges therefor, can solve the problems of creating their own inconvenience, not being able to meet all cycles and load sizes, and dispensers can only accept and dispense one type of treating chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

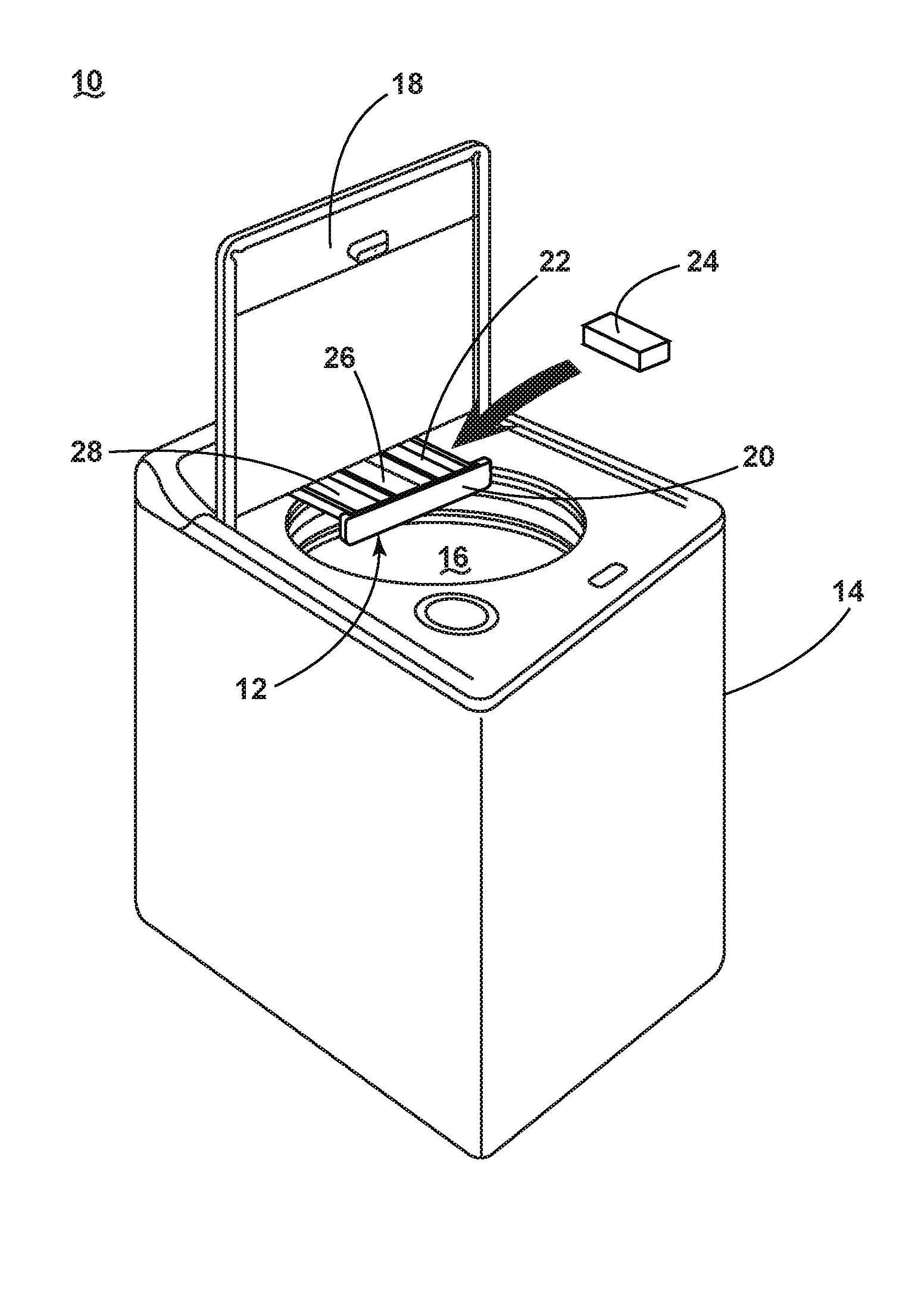

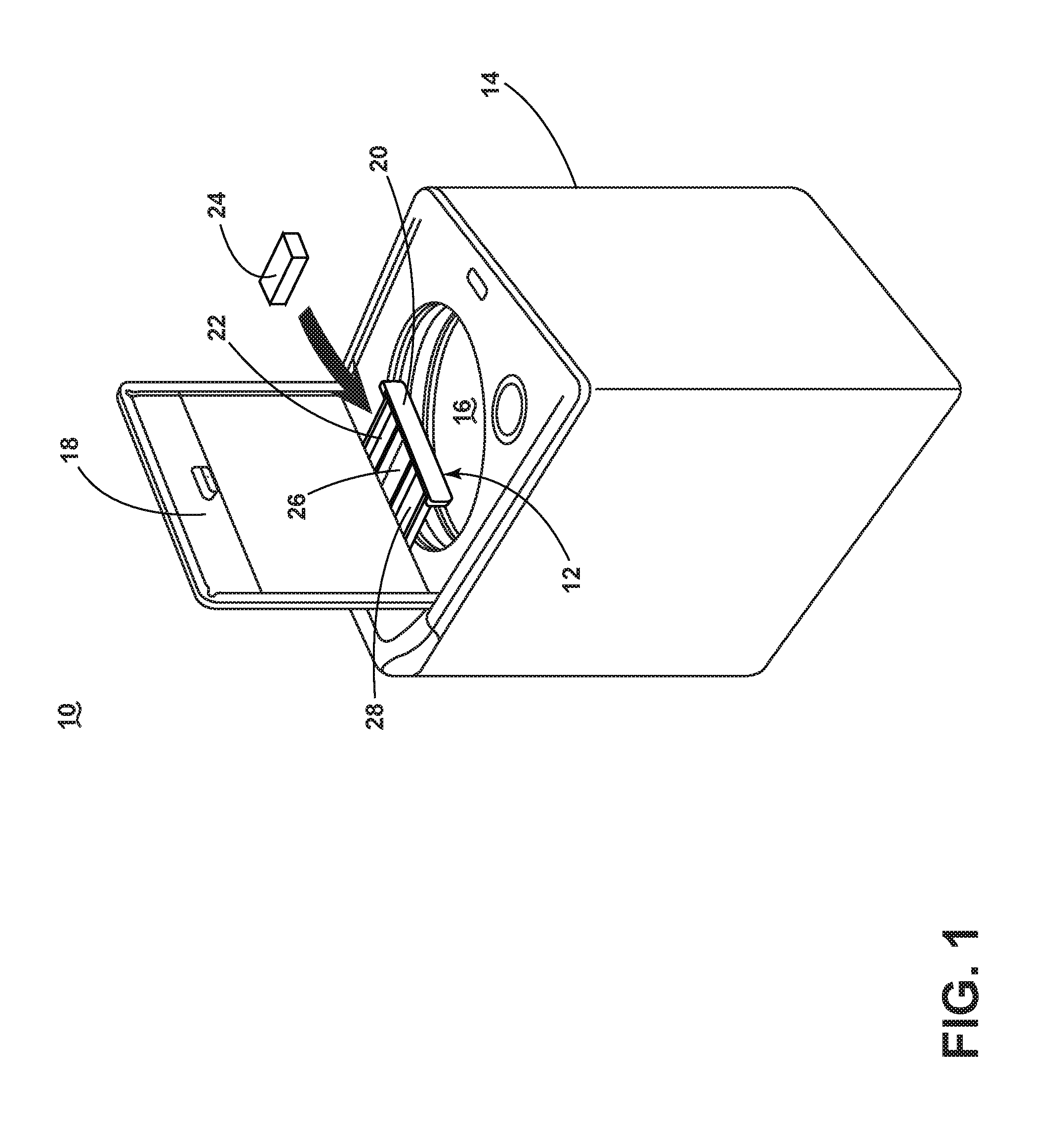

[0028]FIG. 1 is a perspective view of a laundry treating appliance 10 having a dispenser assembly 12 according to the invention. The laundry treating appliance is illustrated in the form of a vertical axis washing machine 10, and shares many features of a traditional automatic washing machine, which will not be described in detail except as necessary for a complete understanding of illustrative embodiments in accordance with the present disclosure.

[0029]As illustrated in FIG. 1, the washing machine 10 can include a housing 14 defining an interior 16. The housing 14 can be a cabinet, chassis, or both. A door or lid 18 is operably coupled with the housing 14 and is selectively moveable between opened and closed positions to close an opening in a top wall of the housing 14, which provides access to the interior 16 of the housing 14.

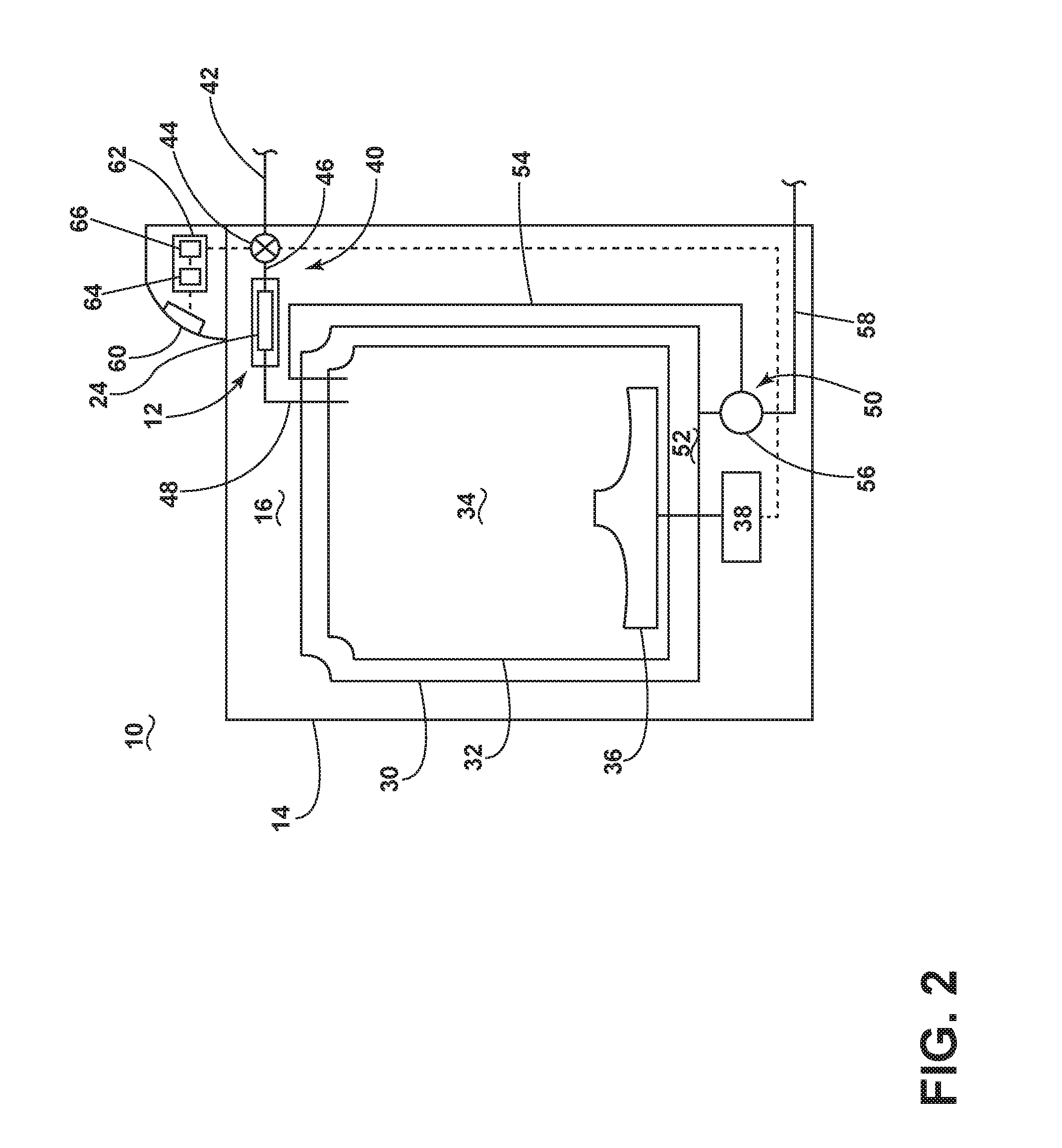

[0030]The housing 14 may also support the dispenser assembly 12 for dispensing treating chemistry during a cycle of operation. The dispenser assembly 12 may...

third embodiment

[0060]FIG. 7 is a schematic sectional view through a dispenser assembly 160 in accordance with the invention. The dispenser assembly 160 may be provided in a laundry treating appliance 162, such as the vertical axis washing machine 10 or the horizontal axis washing machine 150 described above, and shares many features in common with the dispenser assembly 12. The laundry treating appliance 162 is illustrated schematically, and shares many features of a traditional automatic washing machine, which will not be described in detail except as necessary for a complete understanding of illustrative embodiments in accordance with the present disclosure. As shown, the laundry treating appliance 162 includes a tub 164 configured to hold liquid and liquid supply assembly 166 is provided to supply liquid, such as water or a combination of water and one or more treating chemistries, into the tub.

[0061]The dispenser assembly 160 generally comprises a dispenser housing 168 that accommodates a bulk...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap