Mattress Encasement Systems

a mattress and encasement technology, applied in the field of mattresses, can solve the problems of affecting the comfort of the patient, requiring requiring the replacement of the entire mattress, so as to facilitate the making and maneuvering of the bed, and minimize or eliminate the burden of housekeeping individuals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0370]FIGS. 18-21 illustrate a novel method of mattress management which relates to maneuvering a mattress 58 with an encasement 30. As mentioned above, mattresses can be relatively heavy and difficult to rotate. Moreover, an encasement covers up the mattress handles making it even more difficult to rotate the mattress. The novel method for rotating a mattress with an encasement overcomes these problems.

[0371]Initially, as shown in FIG. 18, the zipper 40 is unzipped around all three sides 36. Once the zipper 40 is unzipped, the top panel 32 is draped on the floor on one end, as shown in FIG. 19. Next, as illustrated in FIG. 20, the lower portions 44 of the side panels 36 (FIG. 19) are folded over the sides of the bed skirt 62 or alternatively the sides of the foundation in applications where a bed skirt 62 is not used. Once the lower portions 44 of the side panels 36 are all folded down, the mattress 58 can be rotated, for example, 180 degrees, in a horizontal plane, as generally il...

second embodiment

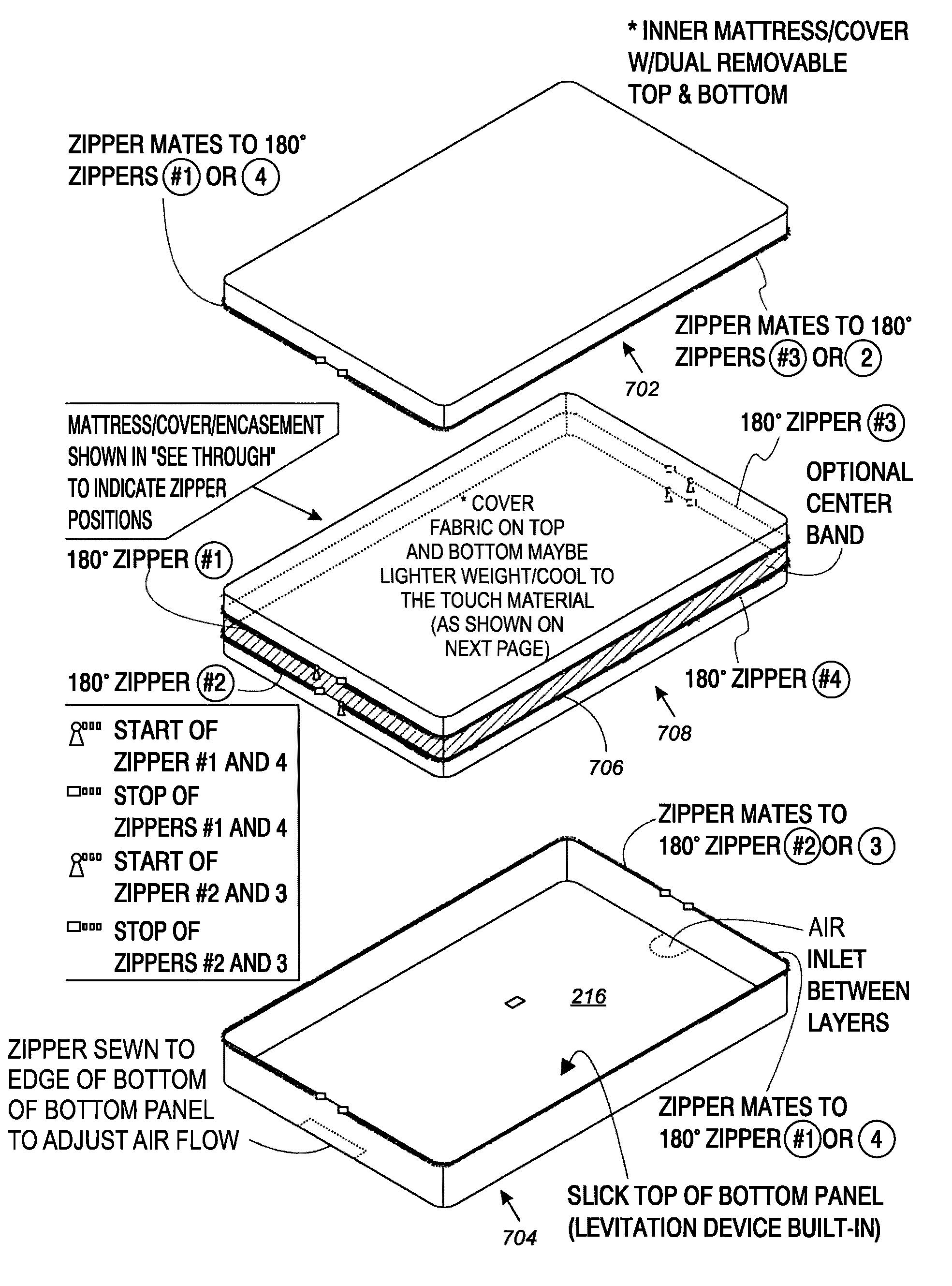

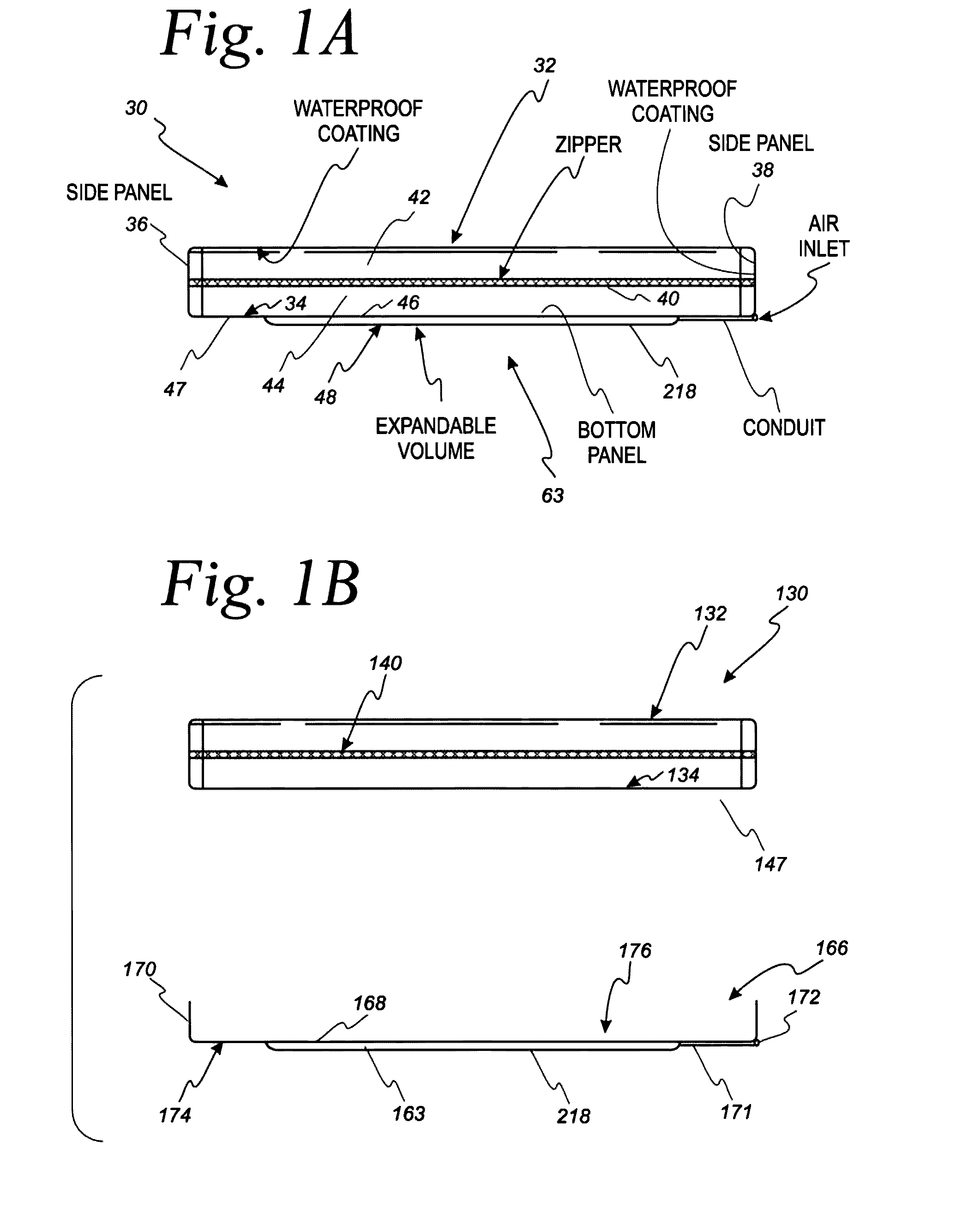

[0377]In a normal mode of operation (FIG. 24), the cover 166 (FIG. 1B) is attached to the encasement 130 so that the inflatable volume 163 is in contact with the bed skirt 62 or foundation 60 and the slick surface 176 (FIG. 1B) of the cover 166 is in contact with the bottom surface 147 of the encasement 130. In this mode of operation, the side panels 170 of the cover 166 may be configured to hide the zipper 140 on the encasement 130. Since the bottom non-slick surface 174 of the cover 166 is in contact with the foundation 60 or bed skirt 62, it will provide a friction grip to hold the encased mattress 130 in place with respect to the foundation 60 of bed skirt 62.

[0378]In order to rotate the mattress 58, as shown in FIGS. 22-24, without removing the encasement 130, the cover 166 or the alternate cover consisting of a bottom panel with no side panels, is detached from the mattress 58 and the encasement 130 and folded down or juxtaposed over the foundation 60 or bed skirt 62 defining ...

third embodiment

[0381]In a normal mode of operation (FIG. 39), the cover 200 is attached to the outside of the encasement 130 so that the non-slick surface 202 is in contact with the foundation 60 or bed skirt 62 and the slick surface 204 is in contact with the bottom surface of the encasement 130. In a rotate mode of operation (FIG. 38), the cover 200 is detached from the encasement 130 and attached or juxtaposed over the foundation 60 or bed skirt 62. In this configuration the bottom surface of the inflatable volume 63 is in contact with the slick surface 204 of the cover 200. After the mattress 58 is rotated in a normal position, the cover 200 can be reattached to the encasement 130.

[0382]Mattress rotation with the cover 201, illustrated in FIGS. 37A, 37B and 37C, is the same as with the cover 200, illustrated in FIG. 39. FIG. 37A illustrates the cover 201 in a normal mode of operation. In this mode of operation, the cover 201 is attached to the underside of the encasement 130. As shown best in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com