Adjustable golf putter head having teeth

a golf putter and adjustment technology, applied in the field of golf putters, can solve the problems of inability to uniformly distribute the dimples over the spherical surface of the ball, the assumption that the previous sentence is correct, and the inability to design a rotatable putter fa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

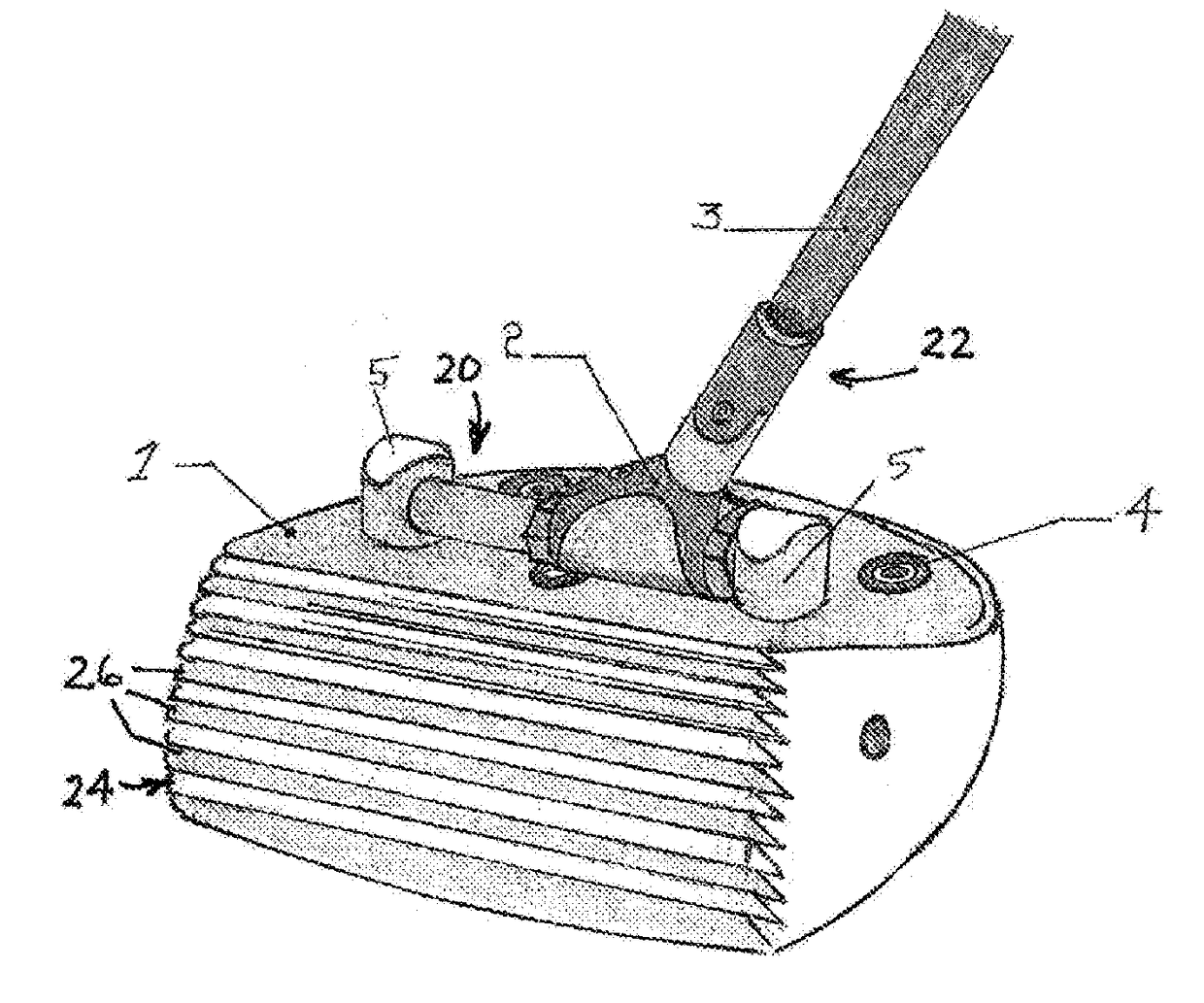

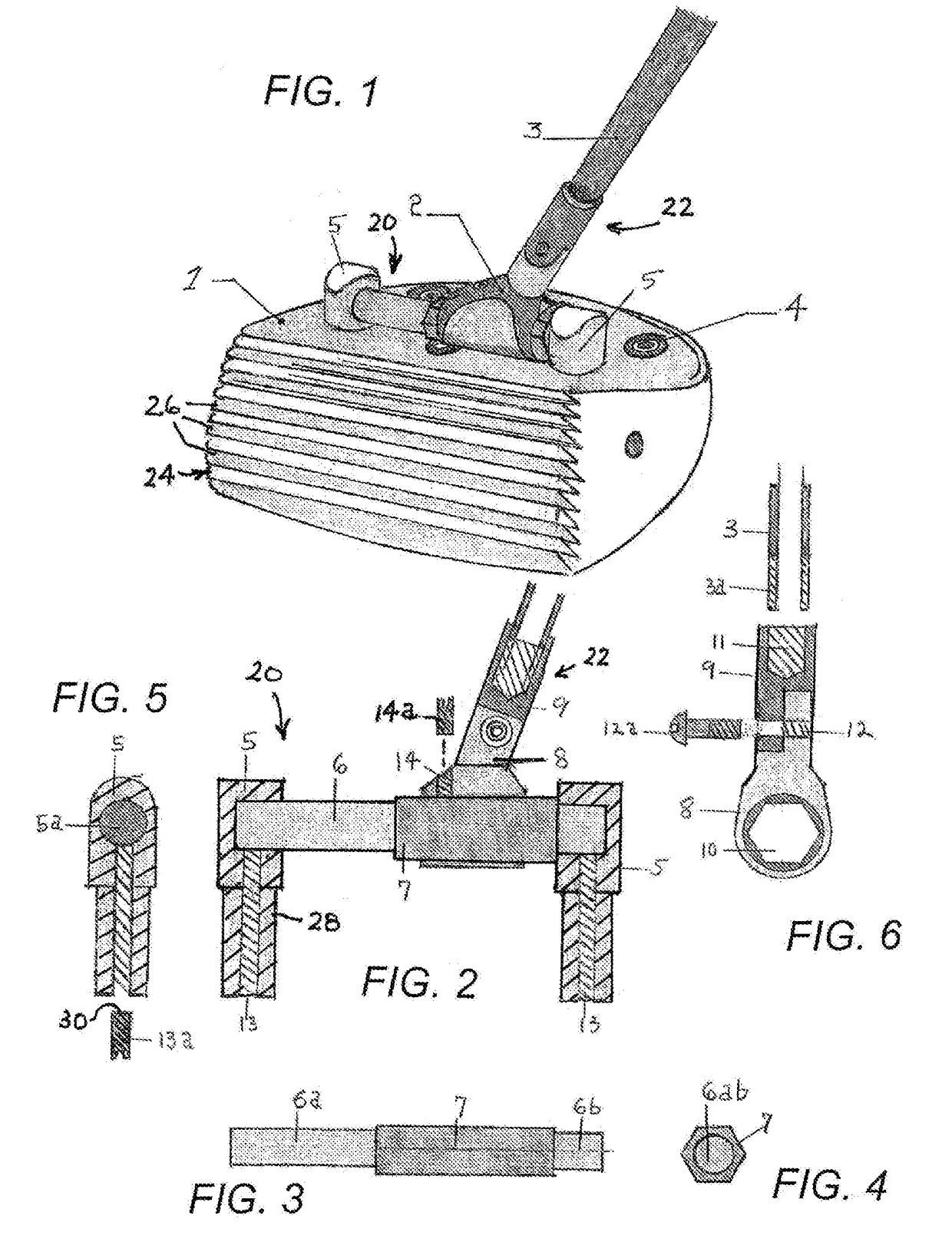

[0052]A preferred embodiment of a golf putter head assembly having a loft-angle adjustment mechanism is shown in FIG. 1. The assembly includes two parts, a putter head body 1 with an attached handle-like structure 20 on top, and a hosel component 22 connected thereto.

[0053]As shown in FIG. 6, hosel component 22 includes an upper section 9 and a lower section 8, adjustably fastened to one another via a bolt 12a, and further includes a slideable annulus-like member 2 that is attached to the bottom of the lower hosel section 8.

[0054]Handle-like attachment structure 20 includes a pair of handle supports or posts 5 which are vertically oriented cylindrical sections attached near the toe and the heel of the putter head body 1. Handle-like attachment structure 20 further includes a horizontally oriented rotatable solid cylindrical section or handle bar 6 lying above the top of the putter body 1, parallel to a front face 24 thereof, the bar 6 being inserted into supports or posts 5. Bar 6 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com