Heat treating furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

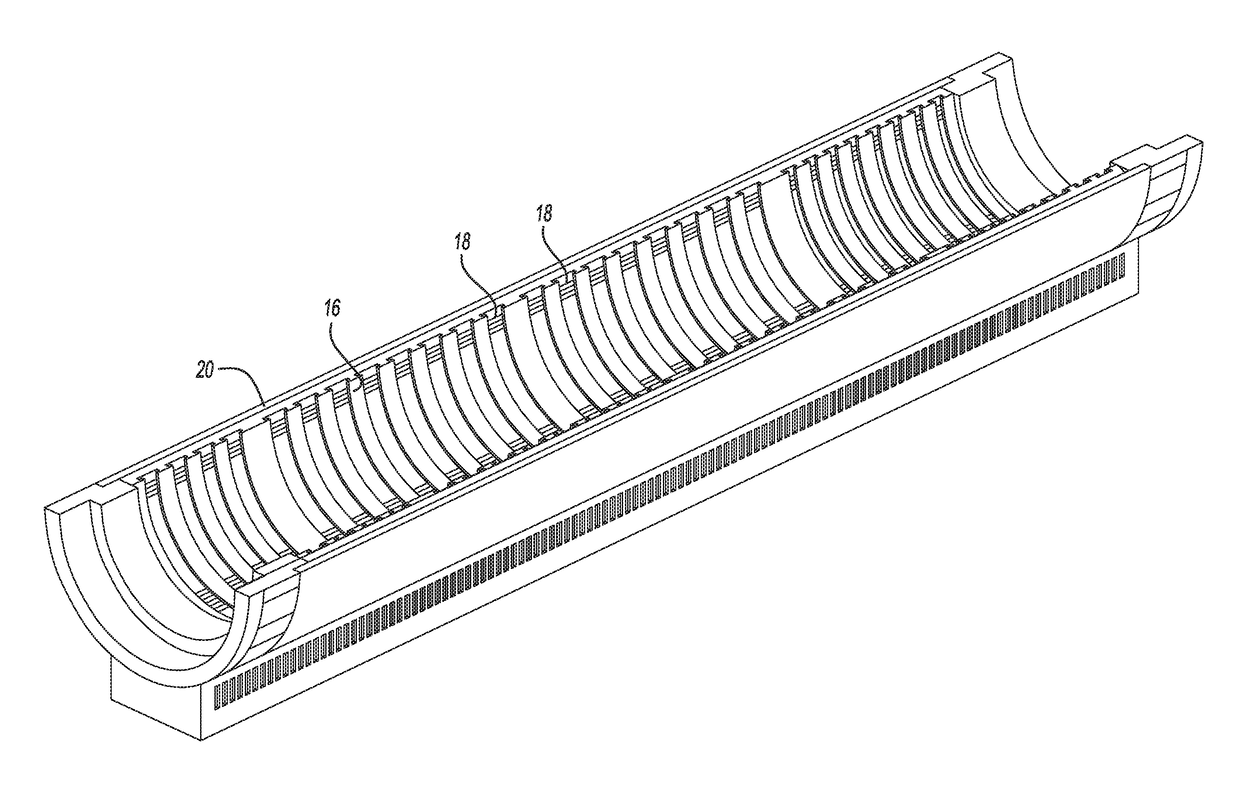

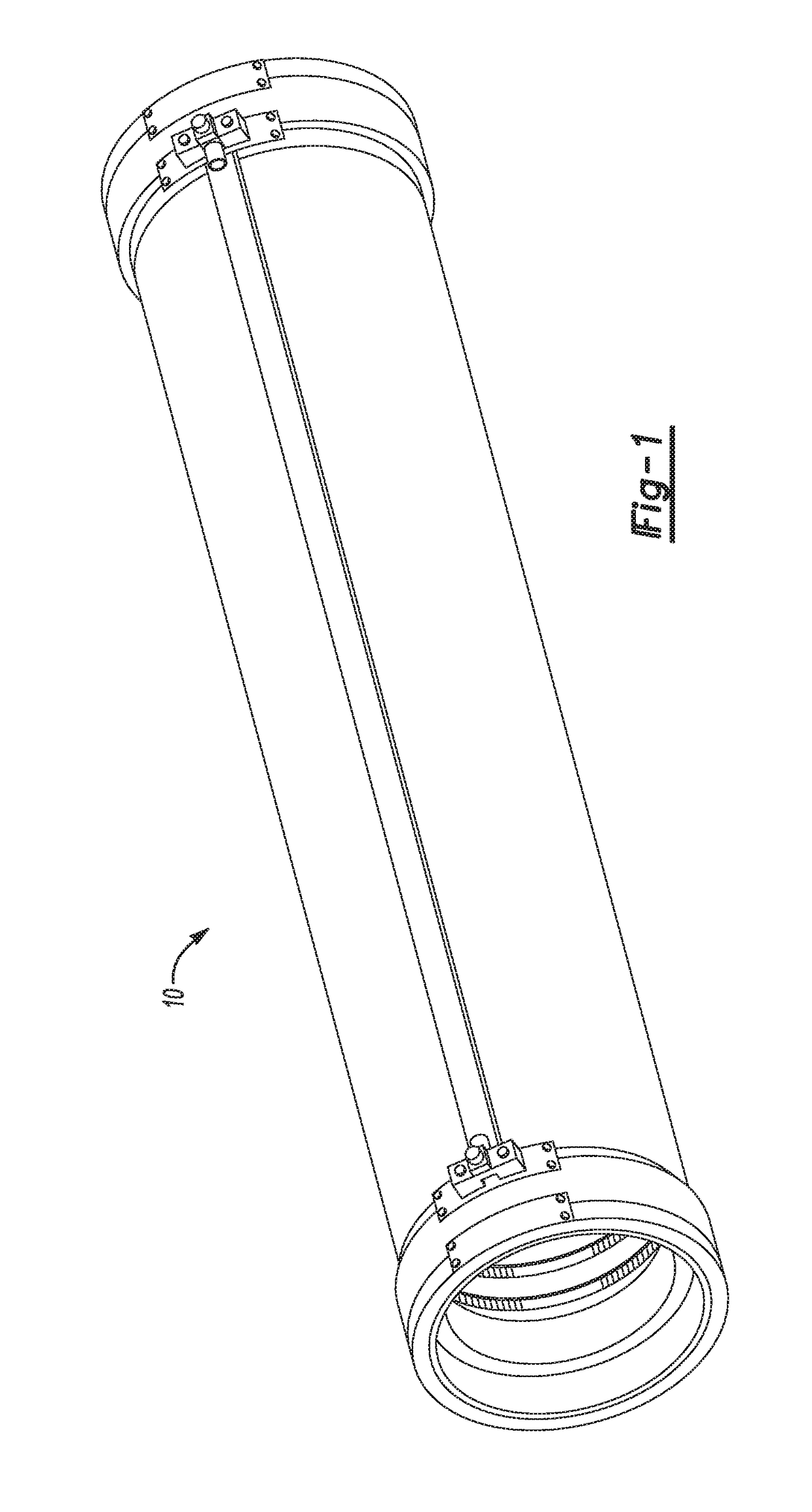

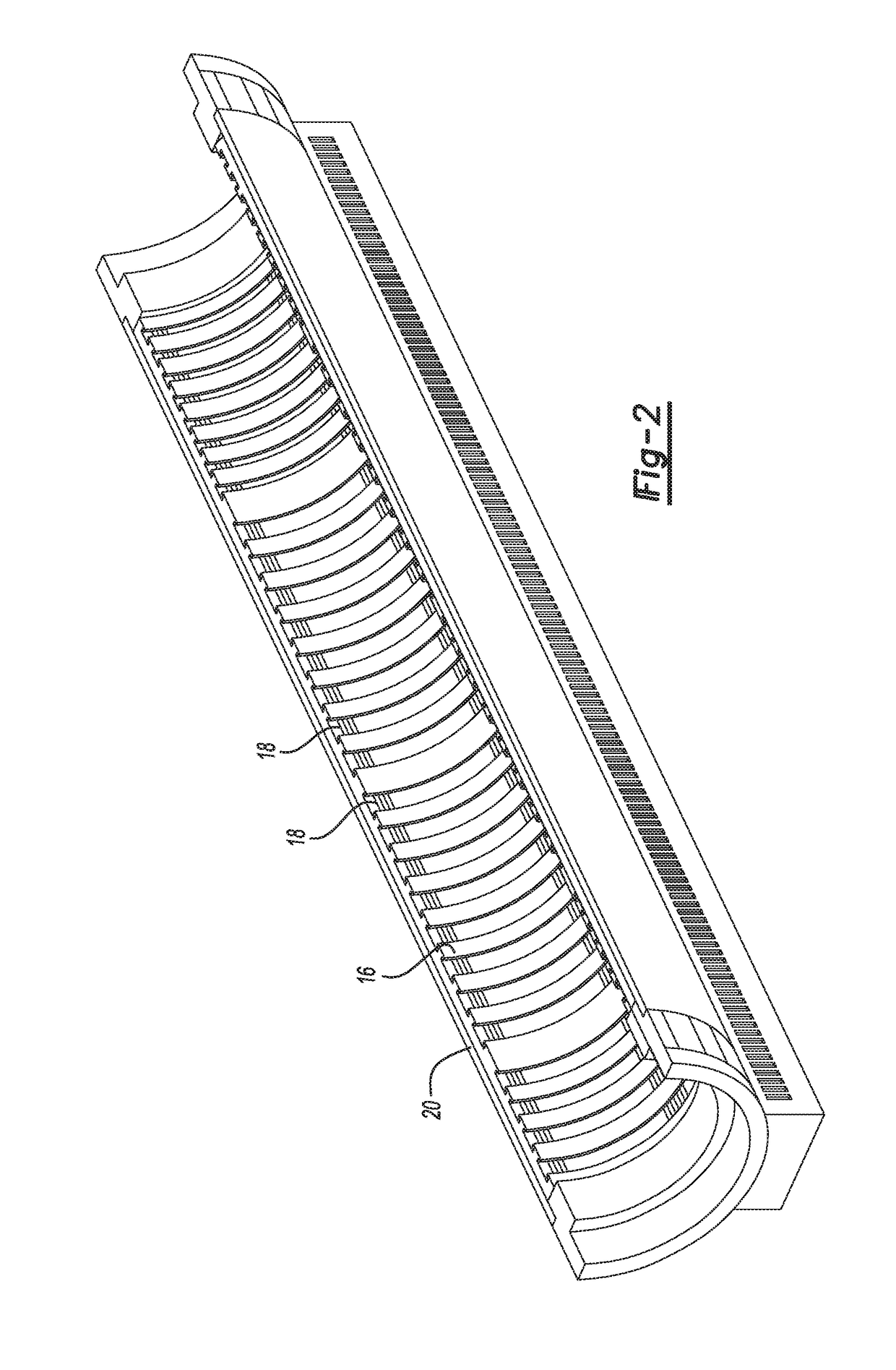

[0016]With reference first to FIGS. 1 and 4, an electrical furnace 10 of the type used for the manufacturing of semiconductor materials is shown. The furnace 10 includes an elongated cylindrical chamber 14 surrounded by an insulation tube 15, typically made of quartz, dimensioned to receive one or more trays or “boats” of semiconductor wafers so that all of the wafers are positioned within the interior of the furnace 10.

[0017]As best shown in FIGS. 2-4, a ceramic fiber inner layer 16 surrounds the furnace chamber 14. The ceramic fiber 16 is rigid in construction and supports a plurality of electrical heating elements 18 which are open to the chamber 14. Consequently, once the electrical heating elements 18 are connected to a source of electrical power, the heating elements heat the interior chamber 14 of the furnace 10 to the desired temperature necessary to process semiconductor wafers positioned within the furnace chamber 14. Furthermore, the ceramic fiber layer 16 and the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com