Baffle for a firearm suppressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

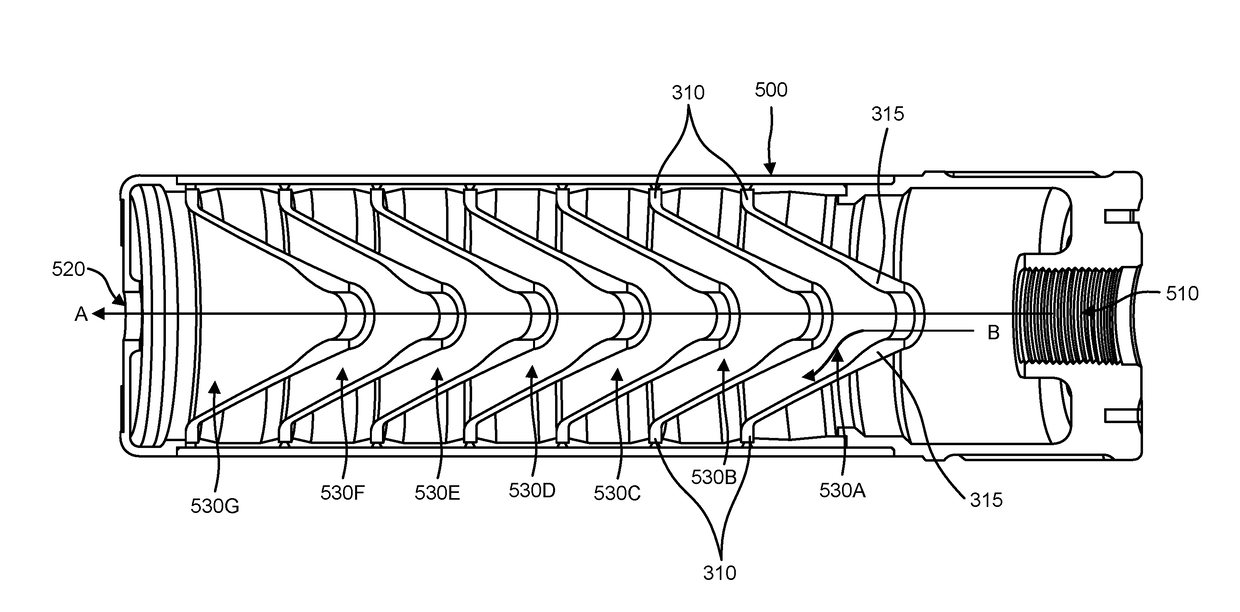

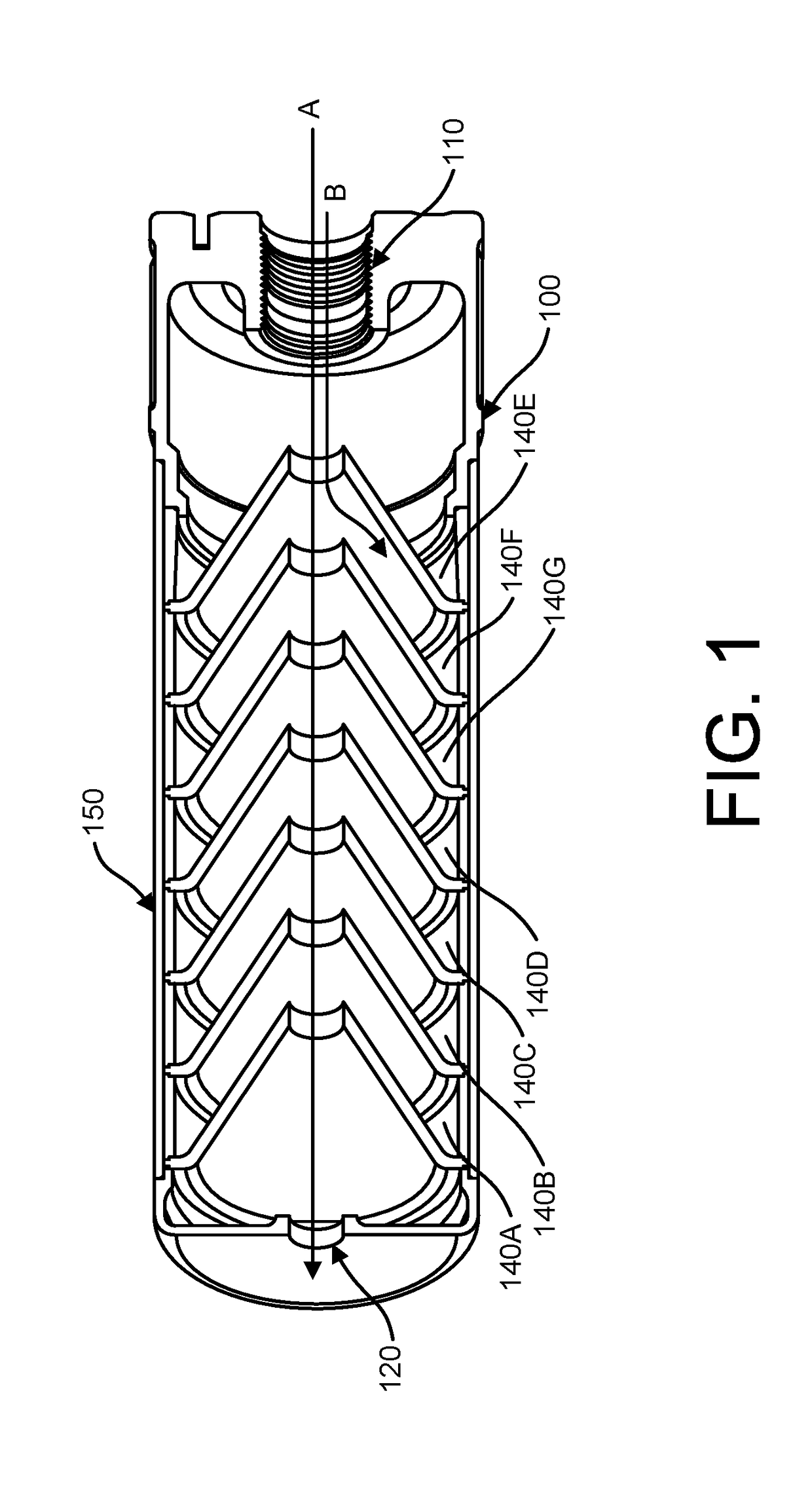

[0016]Turning to FIG. 1, a traditional suppressor or silencer for a firearm is shown in cross sectional detail. The tubular casing 100 is threaded at 110 onto the end of the firearm (not shown). The bullet travels along the path of A, exiting the hole 120. The gas travels along path A and exits out of hole 120. The gas also travels along path B and expands into the chambers created by a series of cone-shaped nested baffles, shown as 140A-G, which usually have a smooth and continuous outer surface 150.

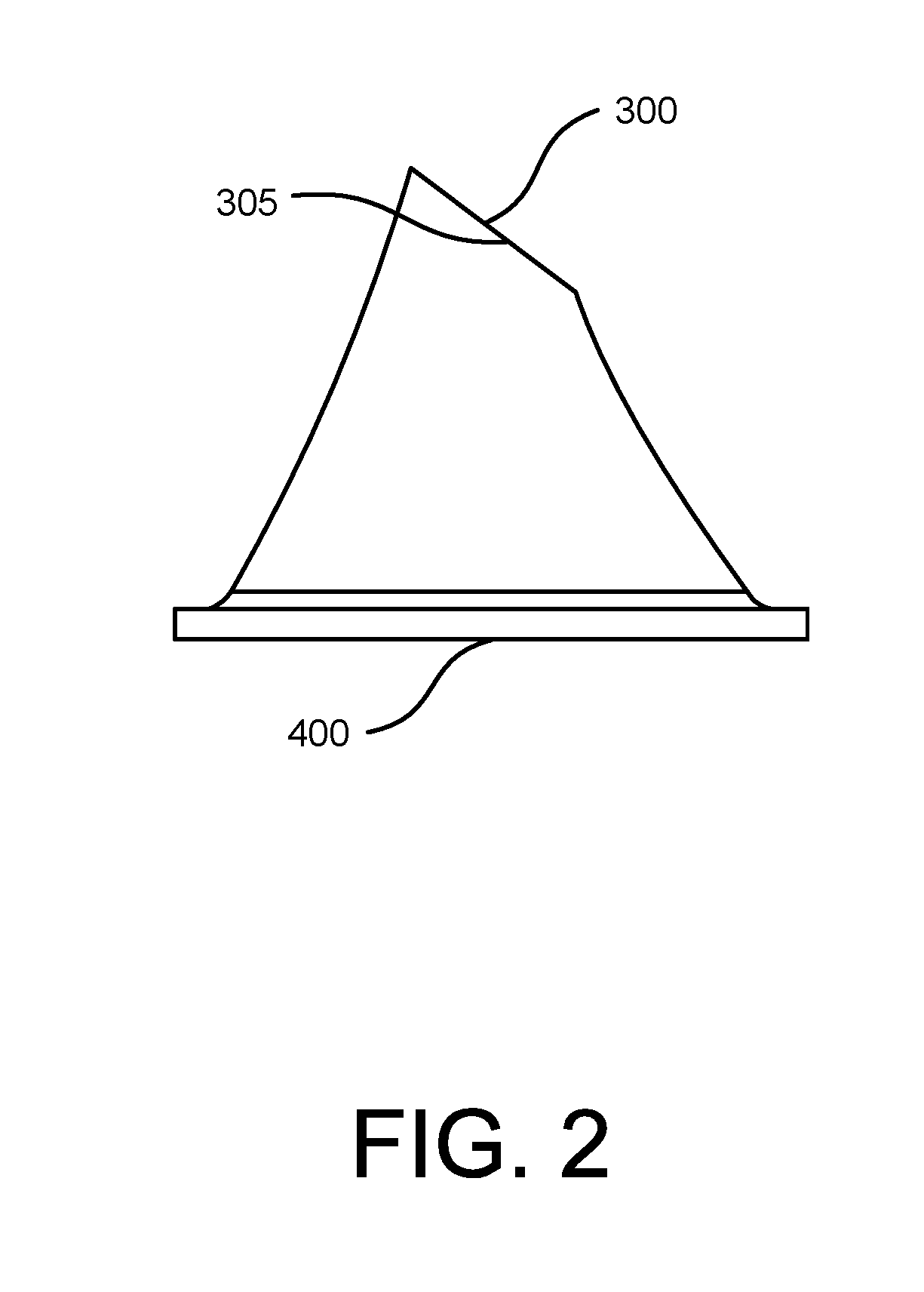

[0017]Turning to FIG. 2, the baffle of the present invention is a generally hollow tubular body of cylindrical cross section casing narrowing to a cone shape having sides that define an inlet and outlet end with an interior and exterior surface. The casing has an inlet end opening 300 for receiving gas into the baffle and an outlet end opening 400 through which the gas exits the baffle. It is noted that the inlet end opening 300 may be angled 305 as shown in FIG. 2 or it may be straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com