Chip package circuit board module

a technology of circuit board and chip, applied in the field of circuit board modules, can solve the problems of low reliability of circuit board, reduced yield, and packaging new led chips at the same position, and achieve the effects of high yield rate, rapid and easy disposal of circuit board, and intensive and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

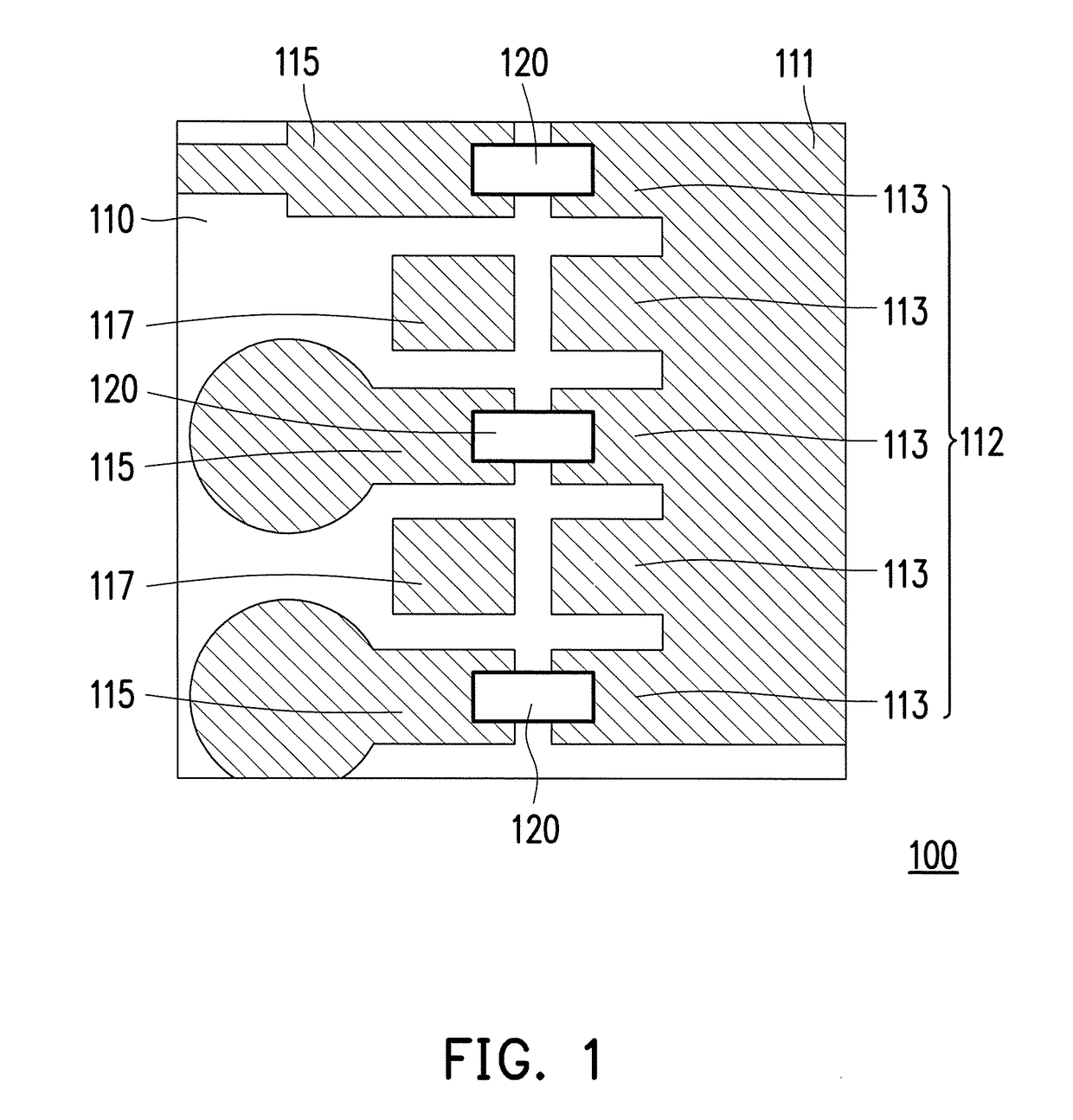

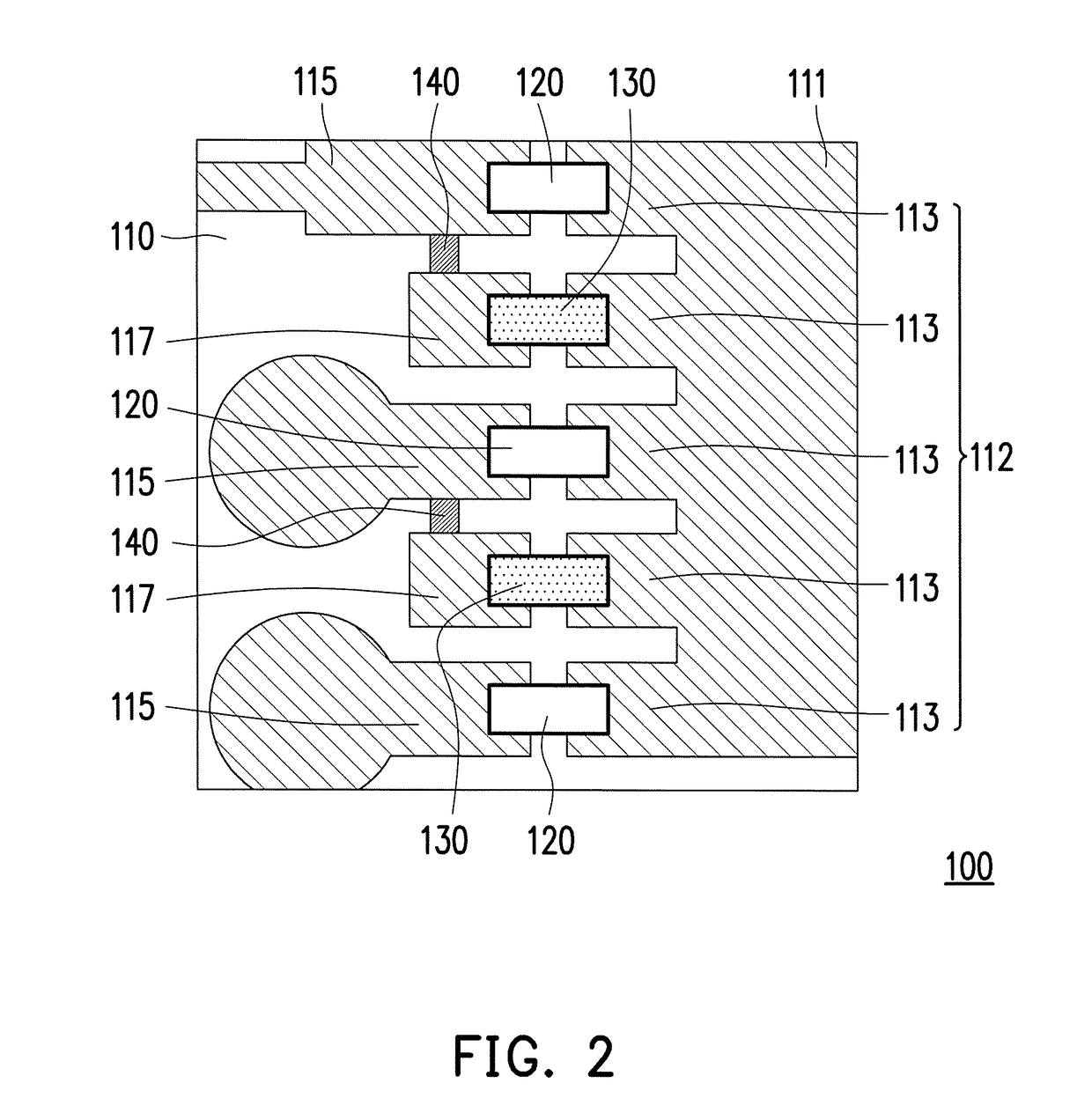

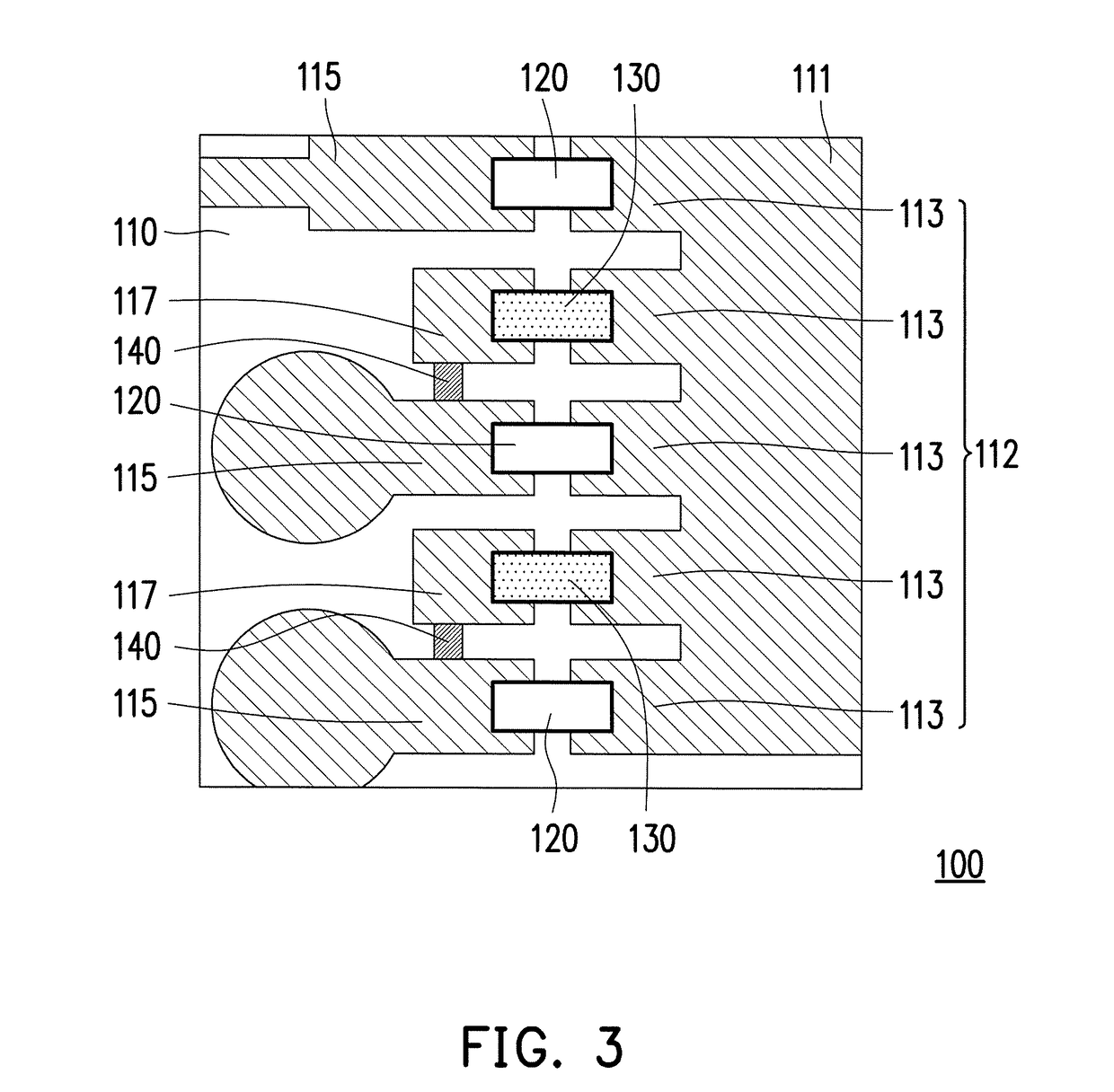

[0030]FIG. 1 is a schematic diagram of a chip package circuit board module according to an embodiment of the invention. With reference to FIG. 1, a chip package circuit board module 100 of the present embodiment includes a circuit board 110 and at least one original chip 120. The circuit board 110 includes at least one first pad 112, at least one second pad 115 and at least one substitute pad 117. In the present embodiment, the first pad 112 includes at least one first branch 113, and these first branches 113 are connected to one another and correspond to the second pad 115 and the substitute pad 117, respectively. In view of FIG. 1, the first branches 113 of the first pad 112 are connected through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com