Method for making cases for firearms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

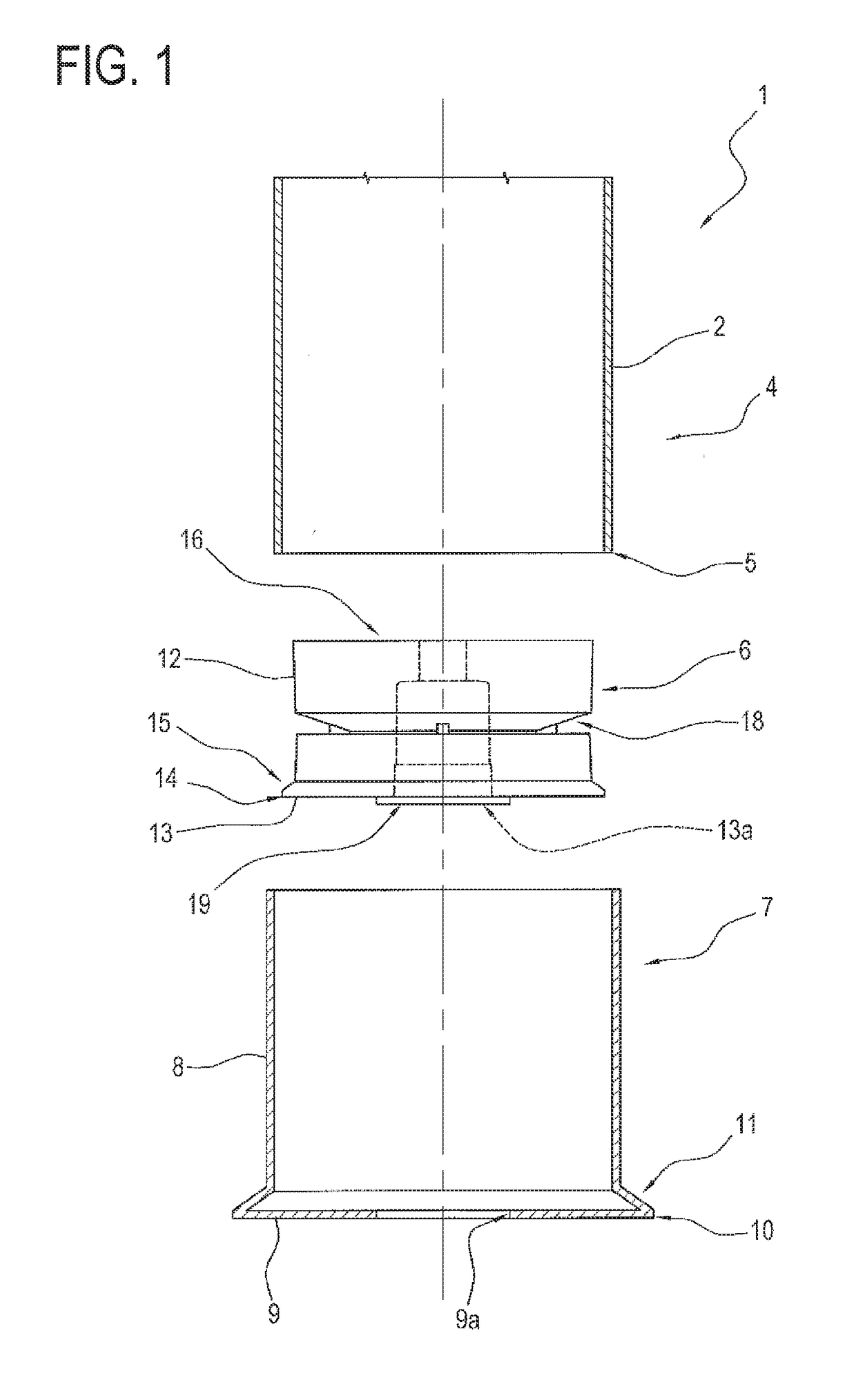

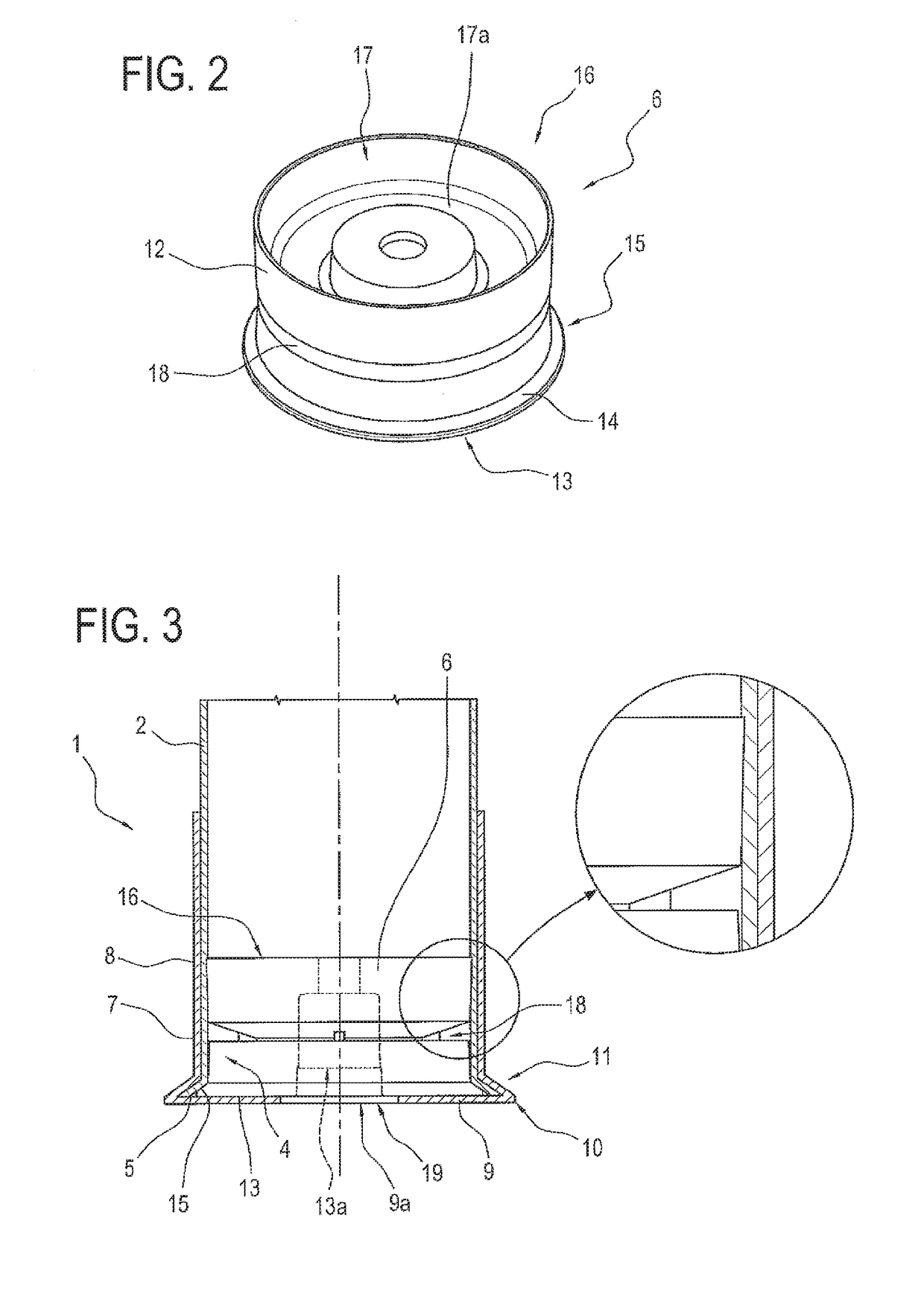

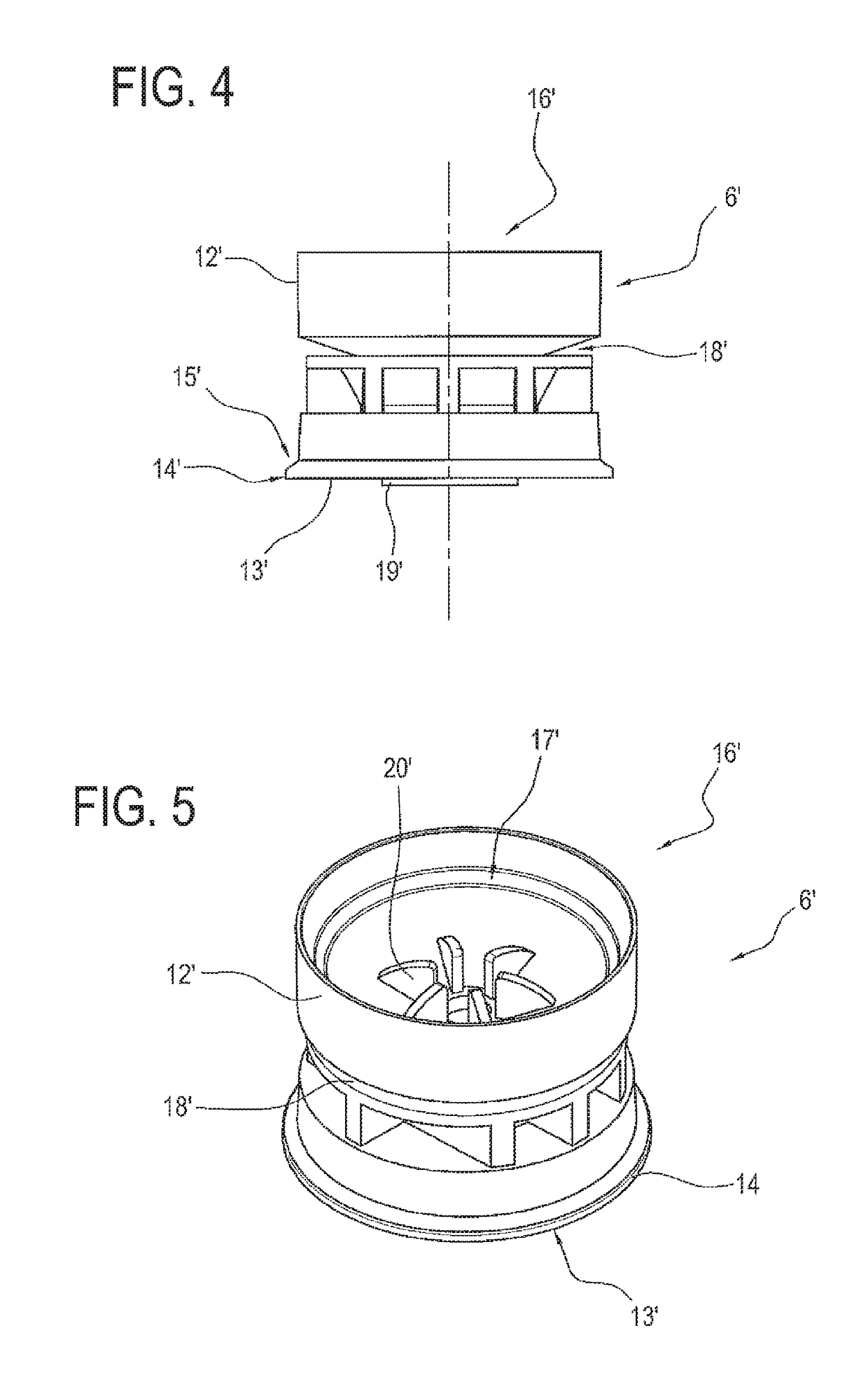

[0032]With reference to FIGS. 1 and 3, the numeral 1 denotes in its entirety a case for firearms comprising:[0033]a substantially cylindrical pipe 2, made of a rigid material and delimited, at its first longitudinal end 4, by a substantially circular end edge 5;[0034]a reinforcing element 6, made of plastically deformable material and inserted inside the first end 4 of the pipe 2; and[0035]a base 7, made of a rigid material, fitted on the first end 4 of the pipe 2 and having a substantially cylindrical shape, with a tubular side wall 8 and with a bottom wall 9 along whose perimeter edge 10 the side wall 8 is flared outwards in such a way as to form a collar 11 which has internally a seat undercut.

[0036]The pipe 2 is preferably made of plastic material or paper and is substantially non-deformable. The inside of the pipe 2 houses the gunpowder, not illustrated. On the opposite side of the first end 4, that is to say, at its second longitudinal end, the pipe 2 holds a projectile, also ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap