Liquid-Crystal Display Devices Containing Polymerisable Compounds

a liquid crystal display and compound technology, applied in the field of liquid crystal display devices containing polymerisable compounds, can solve the problems of reducing the transparency of light, the lcds have the disadvantage of strong viewing angle dependence of contrast, and the response time is extended, so as to facilitate a quick and complete uv-photopolymerisation reaction, reduce image sticking and odf mura in the display, and generate a large and stable pretilt angl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

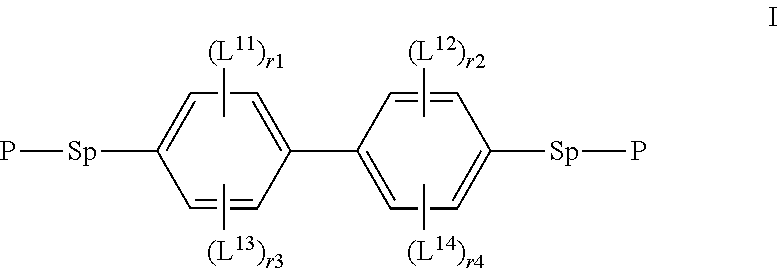

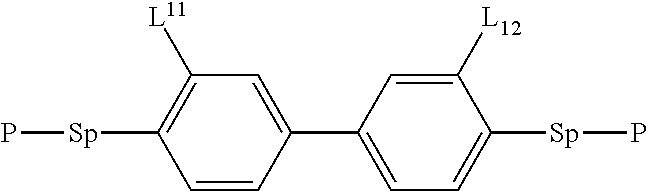

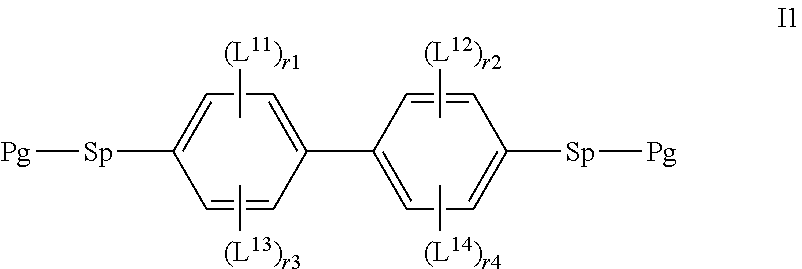

Method used

Image

Examples

example 1

[0526]Polymerisable compound (or “RM”) 1 is prepared as follows.

[0527]3: The preparation of boronic ester 3 is described in WO 2014 / 133361 A1.

[0528]5: A solution of boronic ester 3 (3.0 g, 95%, 36.3 mmol) and phenol 4 (7.0 g, 36.4 mmol) in tetrahydrofuran (120 mL) was added to a stirred solution of sodium metaborate (tetrahydrate, 8.9 g, 64.5 mmol) in water (30 mL) at room temperature. The resulting mixture was treated with bis(triphenylphosphine)-palladium(II) chloride (1.5 g, 2.0 mmol), followed by addition of hydrazine hydrate (0.07 mL, 1.5 mmol). The reaction mixture was stirred overnight at 70° C., before it was treated with 2M HCl and ethyl acetate. Aqueous phase was separated and extracted with ethyl acetate (2 times). The combined organic phase was washed with sat. NaCl solution, dried over Na2SO4, filtered and concentrated in vacuo. The residue was purified with flash chromatography (heptane / ethyl acetate) to give 5 as a yellowish oil. (9.0 g, 65%; GC: 86.0%)

[0529]6: A solu...

examples 2-5

[0532]The following polymerisable monomeric compounds are prepared in analogy to the methods described in Example 1.

Polymerisable Mixture Examples

[0533]The nematic LC host mixture N1 is formulated as follows:

CCH-501 9.00%cl.p.70.0°C.CCH-3514.00%Δn0.0825PCH-53 8.00%Δε−3.5CY-3-O414.00%ε∥3.5CY-5-O413.00%K3 / K11.00CCY-2-1 9.00%γ1141mPa sCCY-3-1 9.00%V02.10VCCY-3-O2 8.00%CCY-5-O2 8.00%CPY-2-O2 8.00%

[0534]The nematic LC host mixture N2 is formulated as follows:

CY-3-O218.00%cl.p.+74.5°C.CPY-2-O210.00%Δn0.1021CPY-3-O210.00%Δε−3.1CCY-3-O2 9.00%ε∥3.5CCY-4-O2 4.00%K3 / K11.16PYP-2-3 9.00%γ186mPa sCC-3-V40.00%V02.29V

[0535]Polymerisable mixtures are prepared by adding various individual polymerisable monomeric compounds (hereinafter referred to as reactive mesogen or “RM”) to nematic LC host mixtures N1 and N2.

[0536]As reference, polymerisable mixtures C11 and C21 are prepared by adding RM C1 which has no substituents, and which is typically used in PSA mixtures of prior art, to nematic LC host mix...

use examples

[0539]The individual polymerisable mixtures are filled into PSA test cells, the RM is polymerised under application of a voltage, and several properties like tilt angle generation, VHR under UV stress and residual RM content are measured.

Residual RM Measurement

[0540]The polymerisation speed is measured by determining the residual content of residual, unpolymerised RM (in % by weight) in the mixture after UV exposure with a given intensity and lamp spectrum after a given UV exposure time. The smaller the residual RM content after a given time interval, the faster the polymerization,

[0541]For this purpose the polymerisable mixtures are inserted into electrooptic test cells from Varitronics made of two soda-lime glass substrates caoted with an ITO electrode layer and a rubbed VA-polyimide alignment layer. The LC layer thickness is approx. 7 μm.

[0542]The test cells are illuminated by a MH-lamp (UV-Cube 2000) using a 320 nm long pass filter (N-WG320) and a light intensity of 100 mW / cm2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tilt angle | aaaaa | aaaaa |

| tilt angle | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com