Method for Manufacturing a Smoking Article Filter

a filter and smoking article technology, applied in the field of filter manufacturing methods for smoking articles, can solve the problems of irrelevant manufacturing tolerances affecting the edges/ends of the filter, and achieve the effect of reducing the number of cigarettes in the filter and reducing the number of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

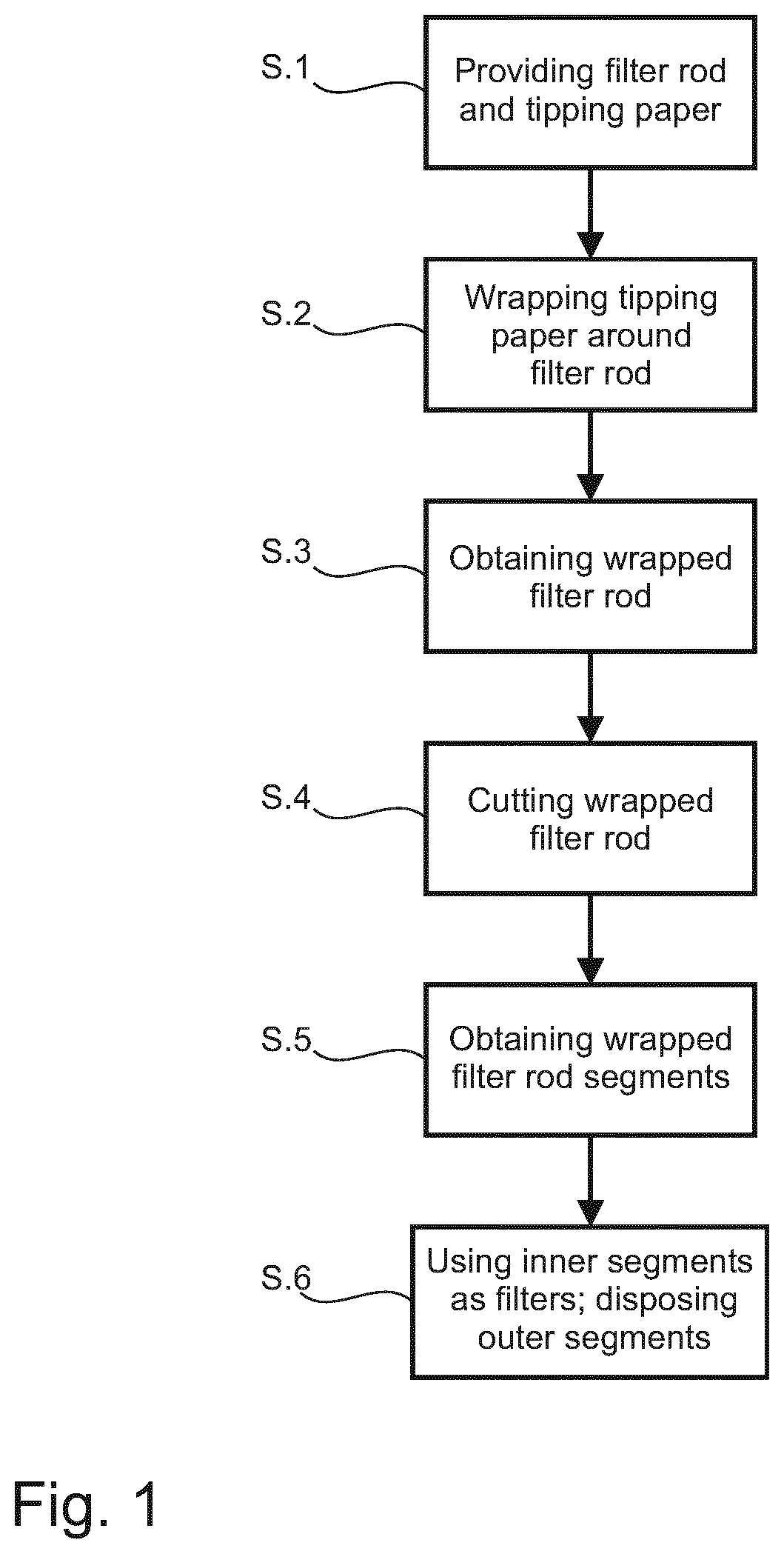

[0045]FIG. 1 shows an overview of a particularly preferred embodiment of the method for producing filters 10 for smoking articles according to the invention.

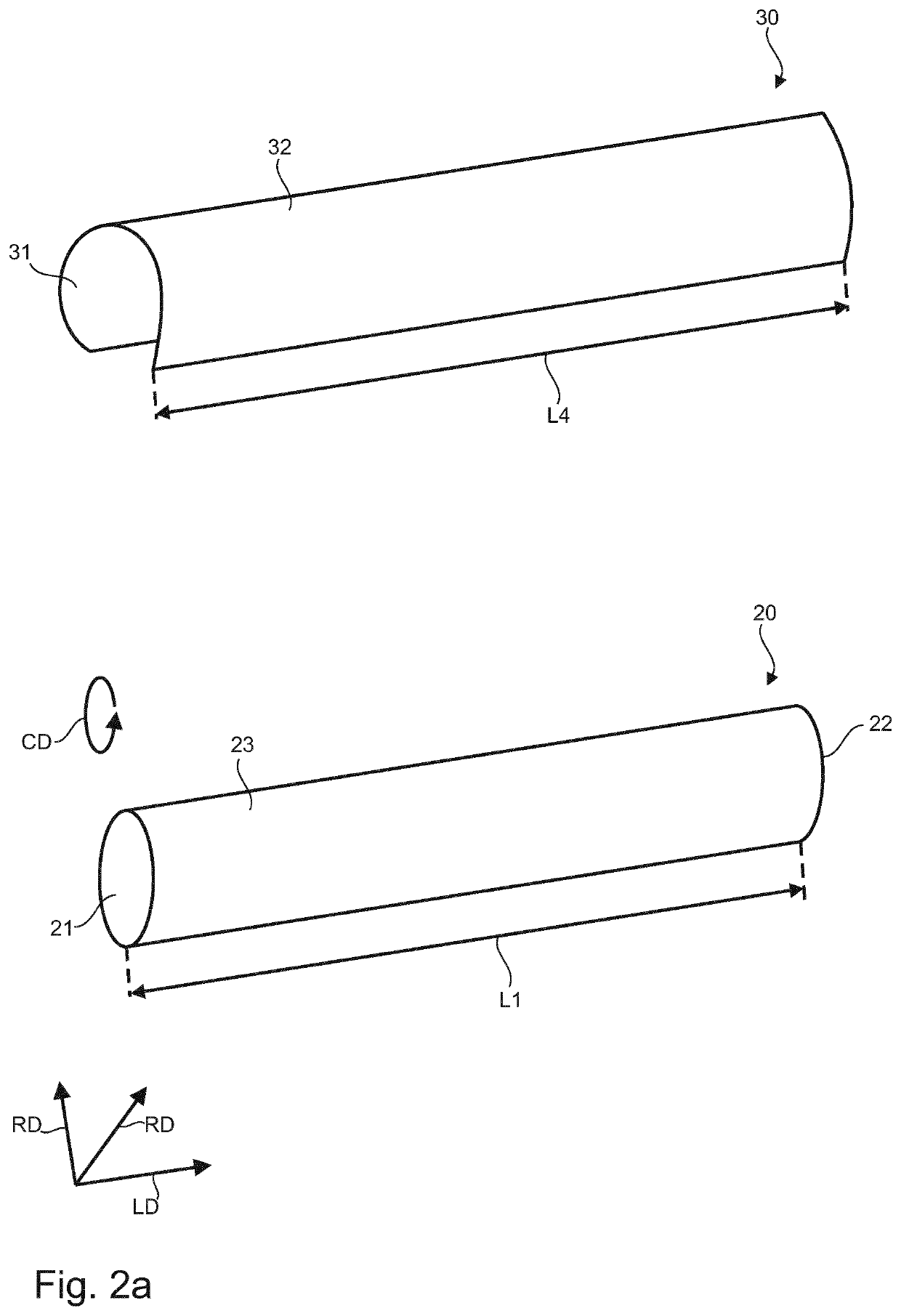

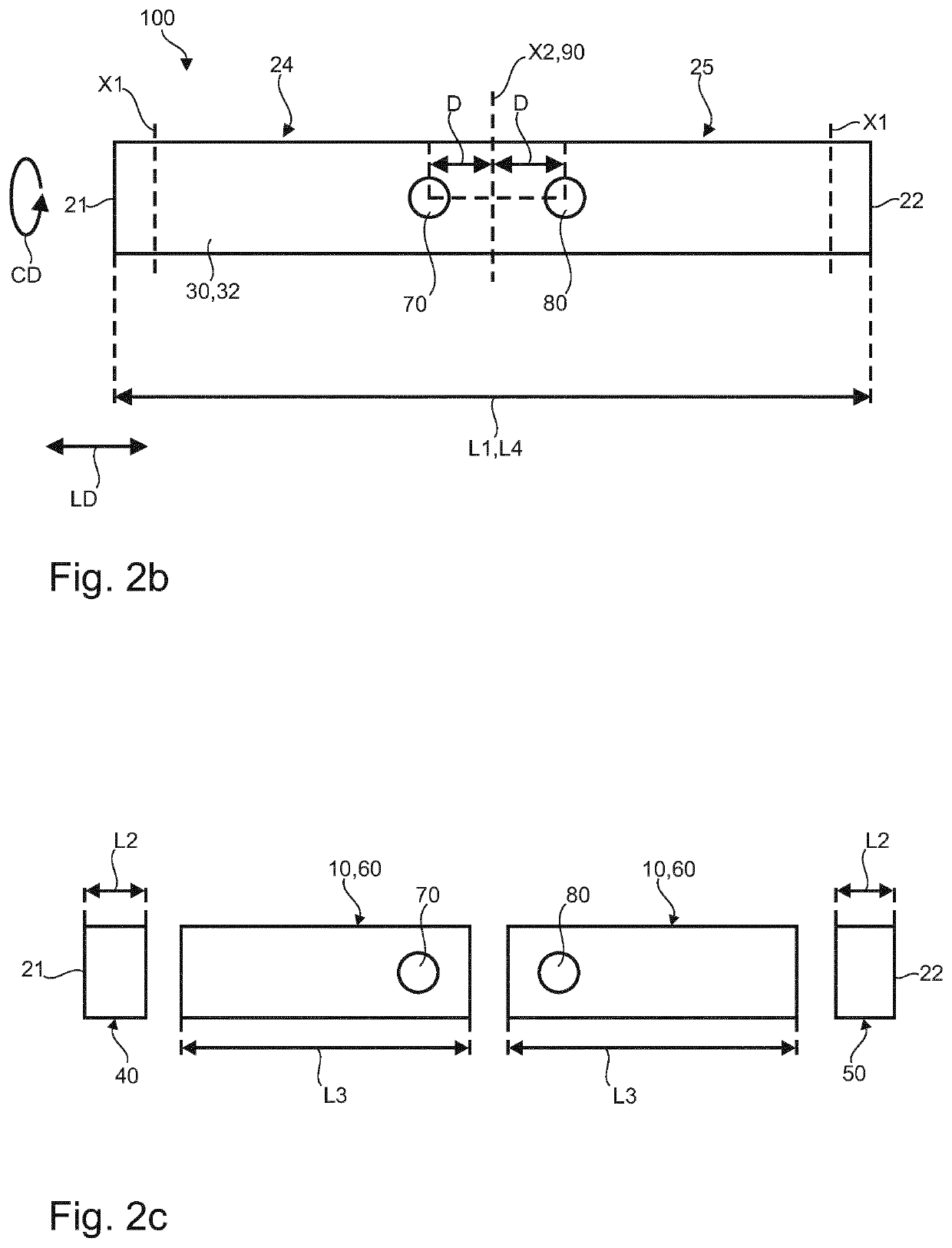

[0046]In a first step S.1, a filter rod 20 and an outer wrapper 30 are provided. The filter rod 20 and the outer wrapper 30 are preferably prefabricated components which are mass-produced. Preferably, a length L4 of the outer wrapper 30 is similar to a length L1 of the filter rod 20.

[0047]In a second step S.2, the outer wrapper 30 is wrapped around the filter rod 20 along a filter rod circumferential direction CD. The outer wrapper 30 covers a circumferential filter rod surface 23 at least partially, wherein an inner outer wrapper surface 31 is in contact with the circumferential filter rod surface 23. Preferably, the outer wrapper 30 and the filter rod 20 are firmly connected by a glue / adhesive connection, wherein the adhesive connection could be present on the inner outer wrapper surface 31 and / or the circumferential filter ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com