Remote sensor for determining proper placement of elevator slips

a technology of elevator slips and remote sensors, which is applied in the direction of drilling casings, drilling pipes, surveying, etc., can solve the problems of rig personnel injury, pipe weight, body may not securely grip such pipes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

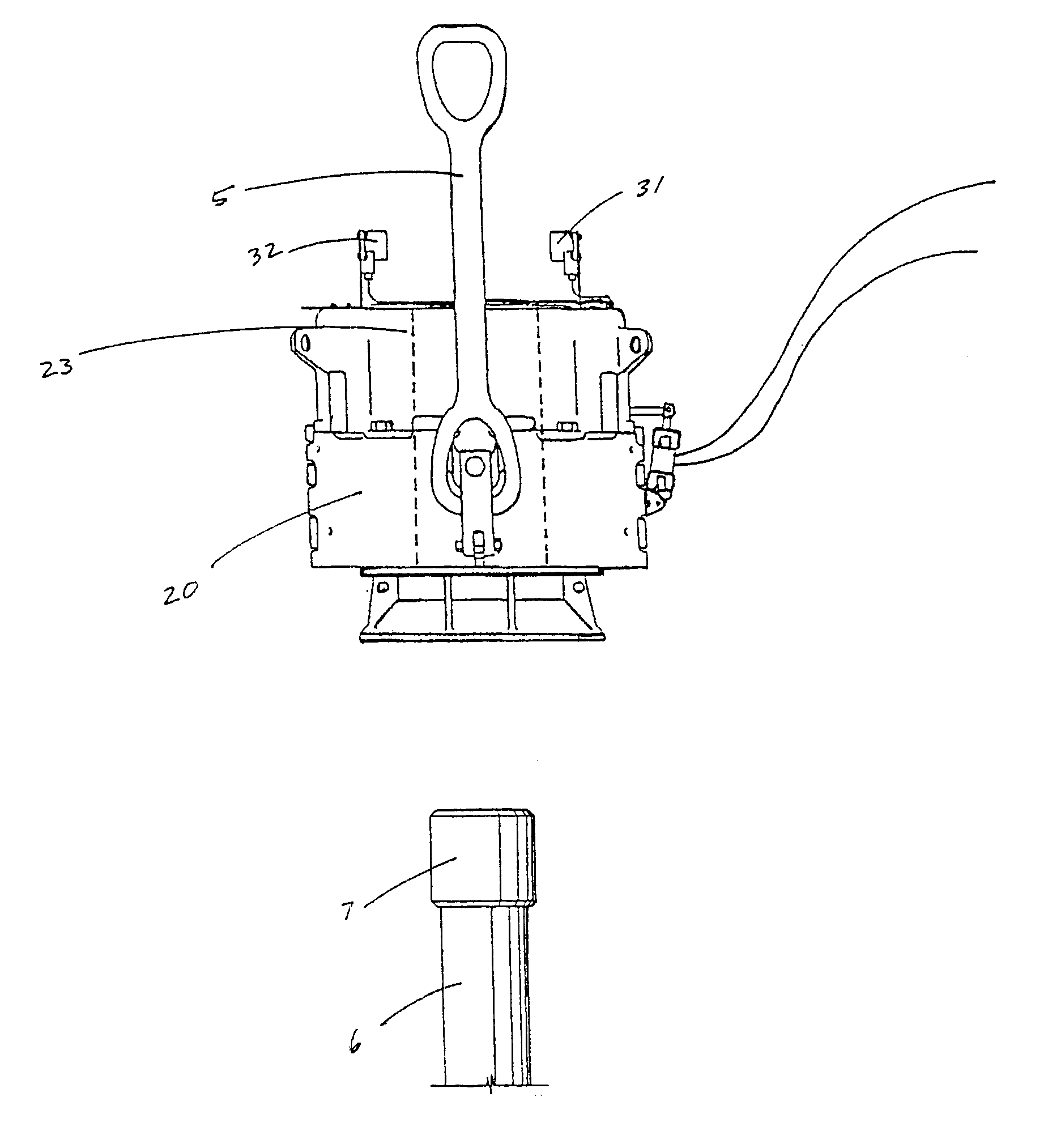

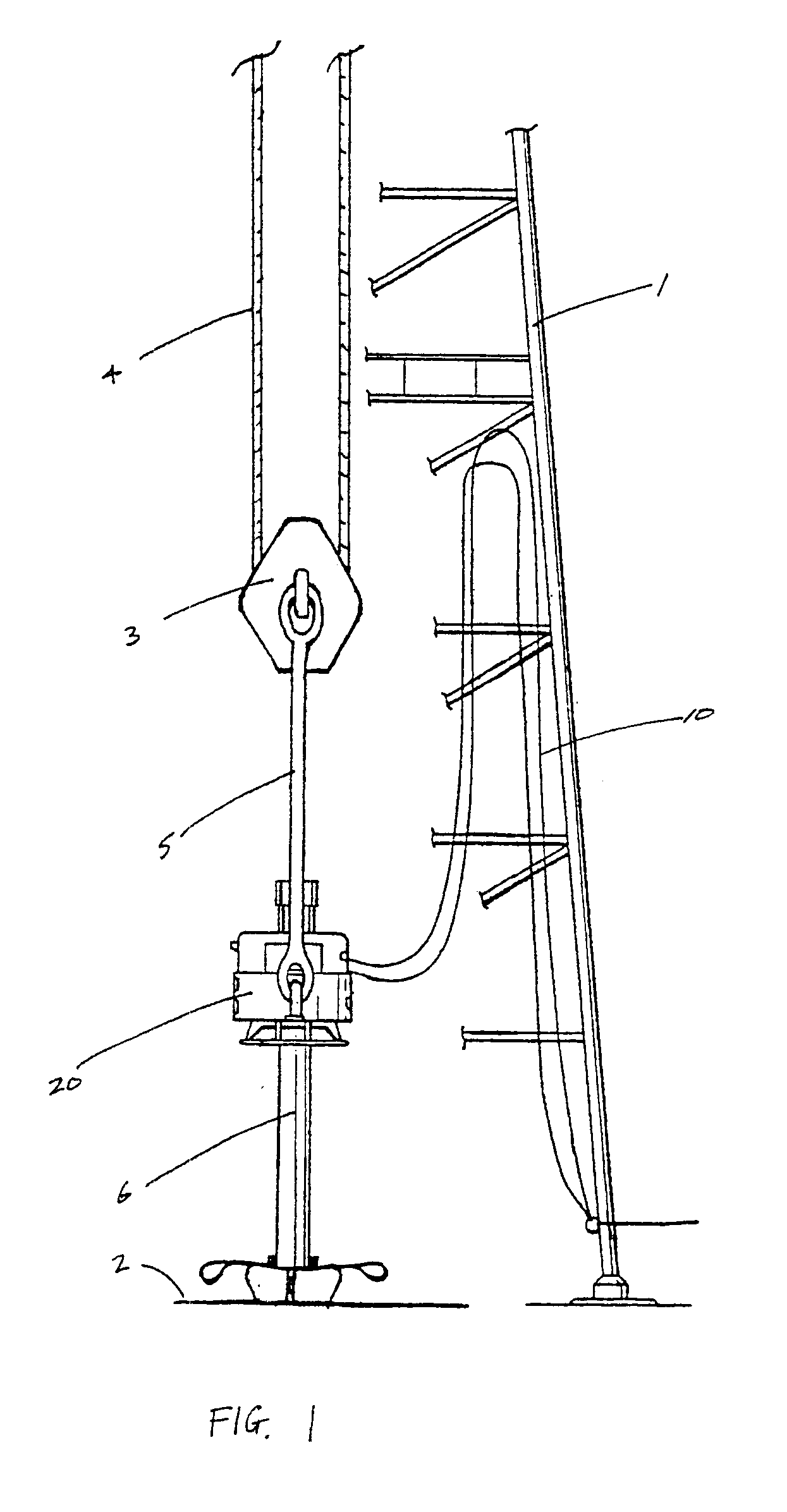

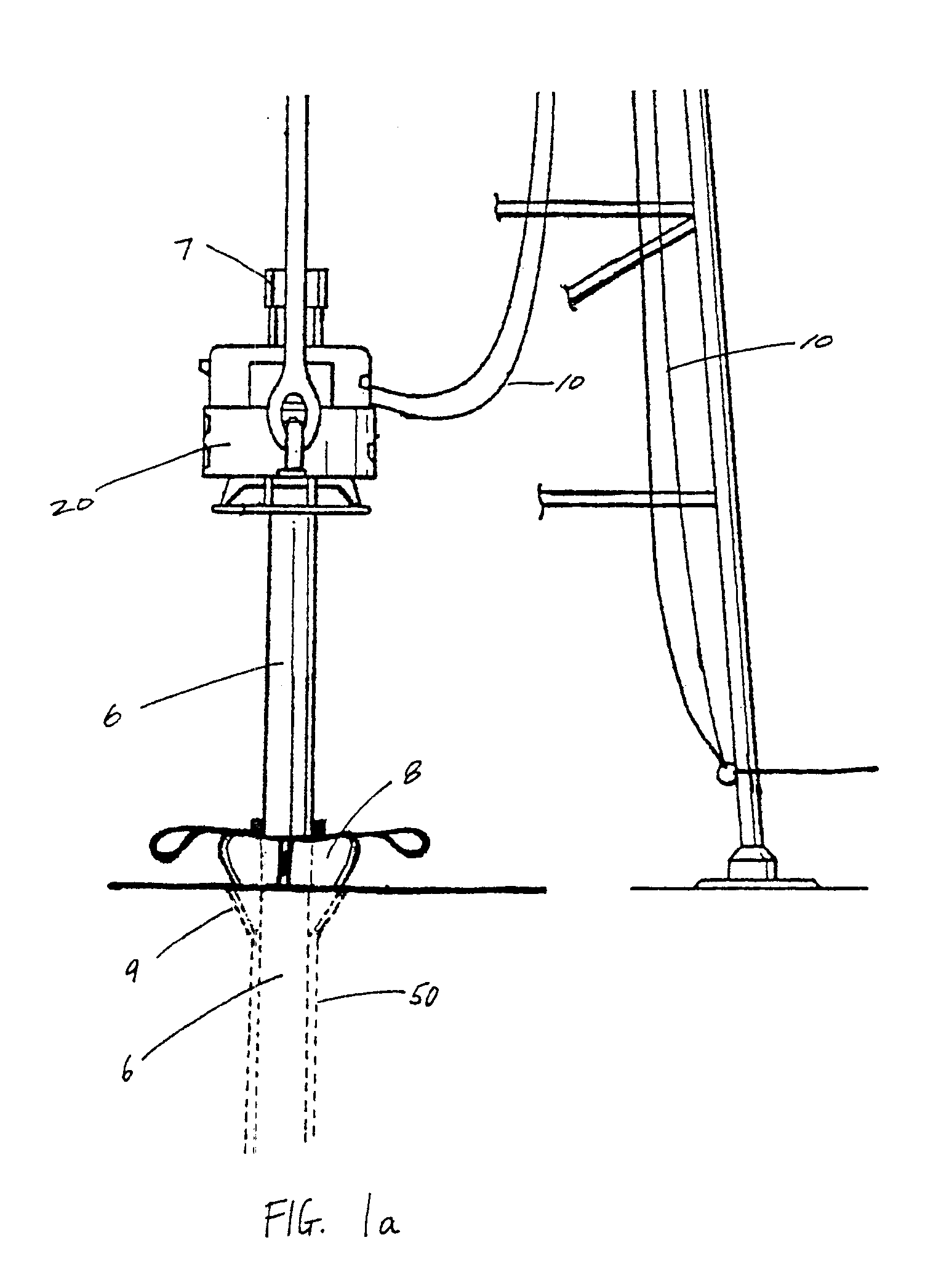

Referring to FIG. 1, a standard configuration of equipment on a drilling rig used for running pipe into a wellbore, and for pulling pipe out of said wellbore, is shown. Derrick 1 extends above the rig floor 2 and supports traveling block 3 via drill line 4. Bails 5 are used to support pipe handling elevators 20 from traveling block 3. A driller or other operator, typically positioned on or near rig floor 2, operates drawworks on said rig, thereby causing traveling block 3 to be vertically raised and / or lowered within derrick 1 as desired. Accordingly, by raising and lowering said traveling block 3 via drill line 4, elevators 20 can be positioned at desired vertical locations within derrick 1.

Still referring to FIG. 1, elevators 20 are shown latched on the upper portion of pipe joint 6. Elevators 20 have a central bore therethrough; pipe joint 6 is received within said central bore of elevators 20. Elevators 20 can be positioned at desired locations along the length of the upper por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com