Managing maintenance for an item of equipment

a technology for maintenance and equipment, applied in the direction of transmission monitoring, instruments, nuclear elements, etc., can solve the problems of equipment failure during routine operation, maintenance of equipment items, and equipment failures, etc., to eliminate or reduce equipment downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

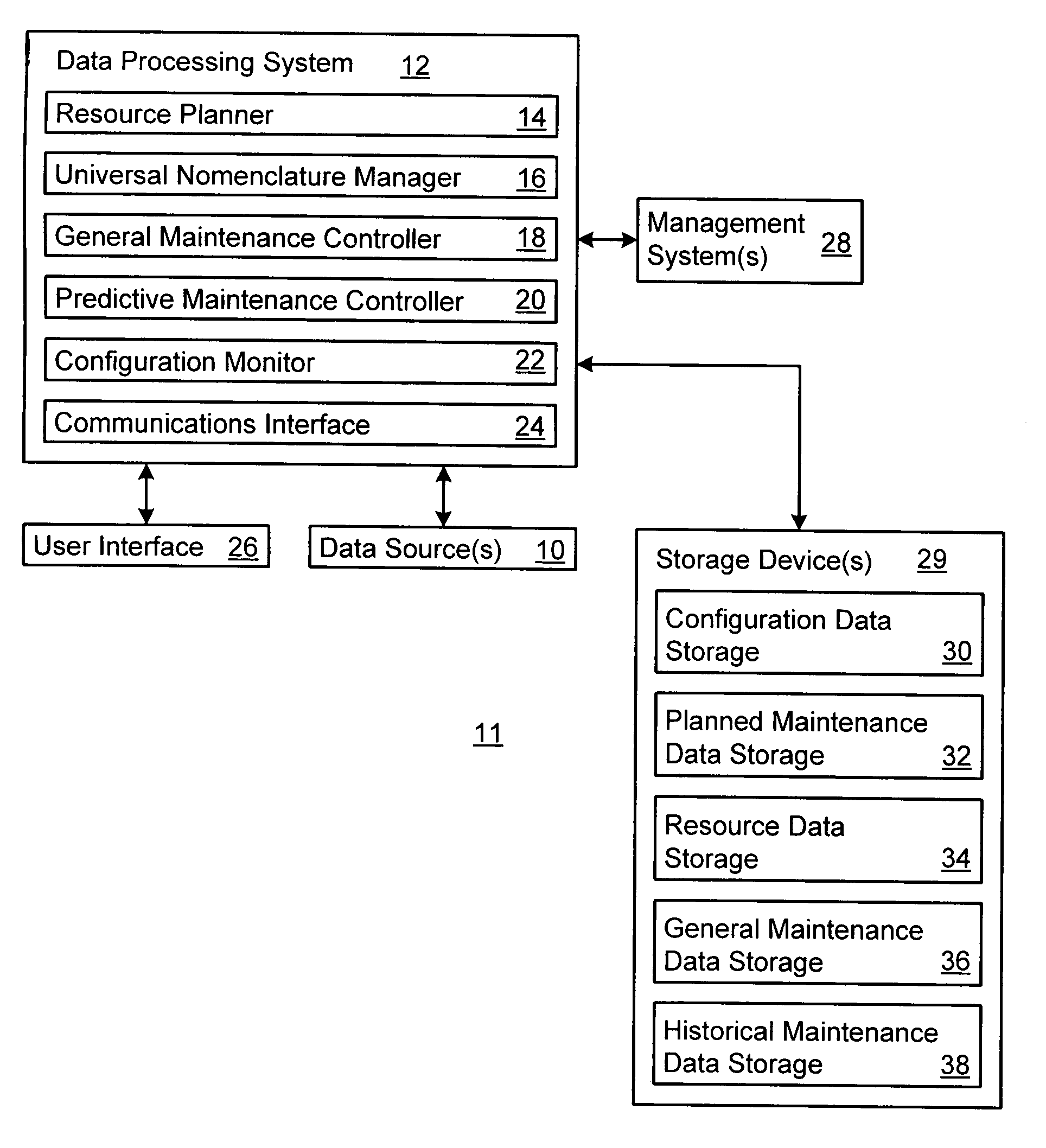

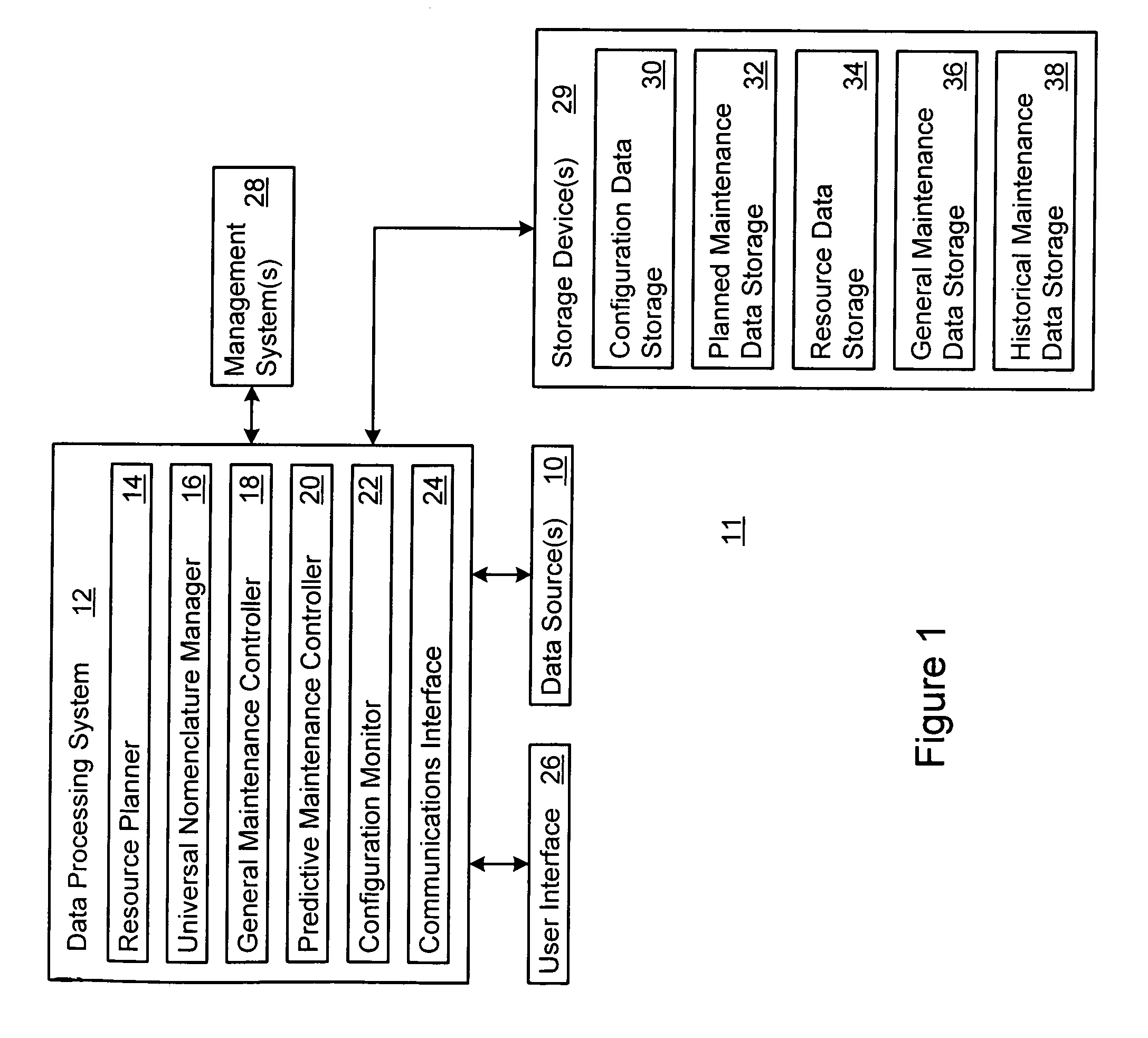

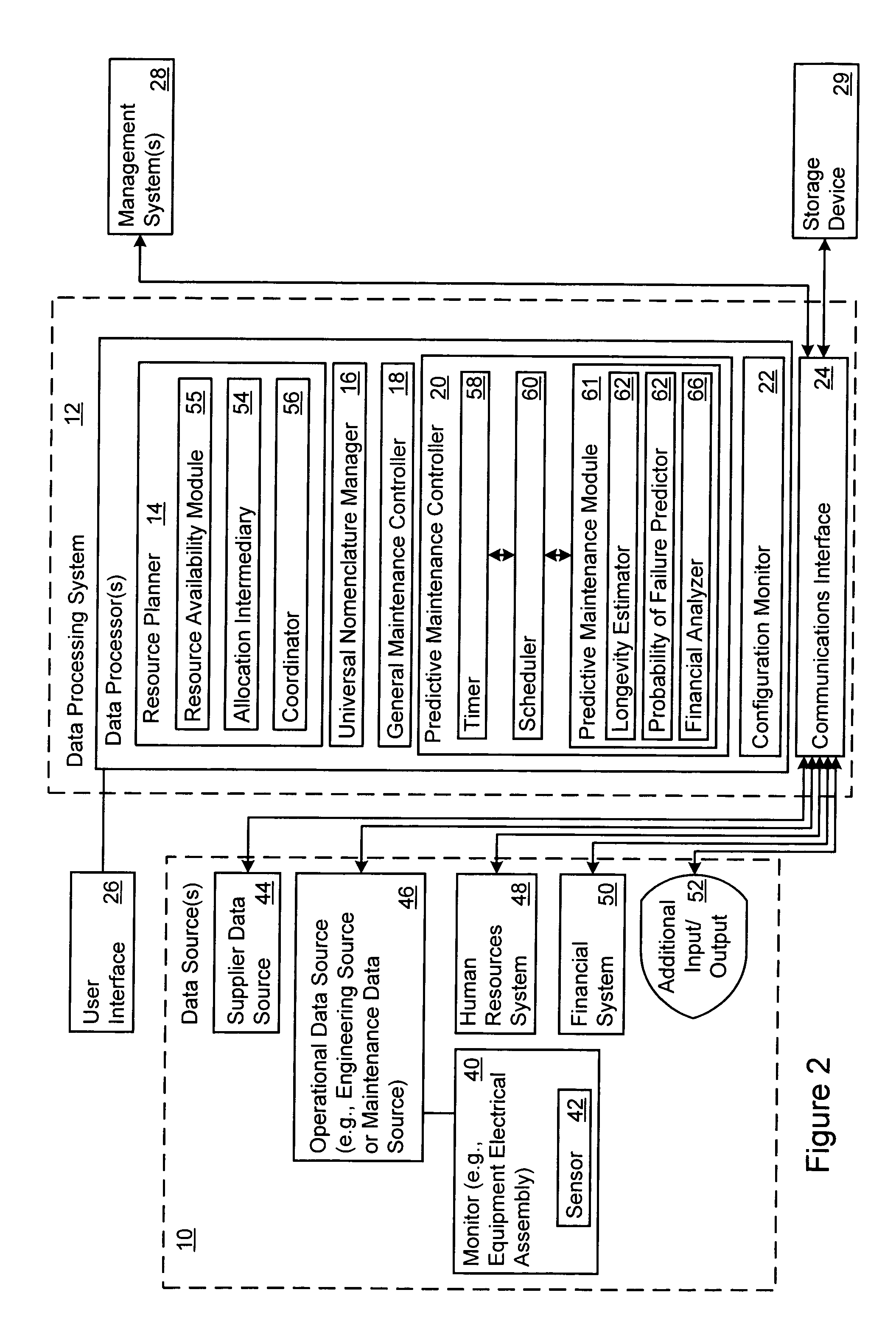

Image

Examples

Embodiment Construction

[0018]As used herein, a maintenance provider shall include any person or business entity that performs or supports maintenance, repair, or overhaul activity (i.e., an MRO activity) for at least one item of equipment. Similarly, as used herein, maintenance, a maintenance activity or a maintenance task shall include at least one of maintenance, repair, and overhaul (i.e., MRO) of an item of equipment or a component of the equipment, unless otherwise noted.

[0019]A component means a component of an item of equipment, a sub-component of an item of equipment, an assembly of an item of equipment, a system of an item of equipment, or any other constituent part of an item of equipment. A component may be defined based on its relationship with other components in an item of equipment and based upon the context of its use in the equipment. A component may include, but need not include, one or more sub-components. An assembly may comprise a group of integrated or inter-related components. A mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com