Assembly and method for cryo-preservation of specimens in a cryogen-free environment

a specimen and environment technology, applied in the field of assembly and preservation of specimens, can solve the problems of negligible complexity in including the two cryogenic stages in a single cooler, and achieve the effects of minimizing storage temperature fluctuations, reducing labor intensity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

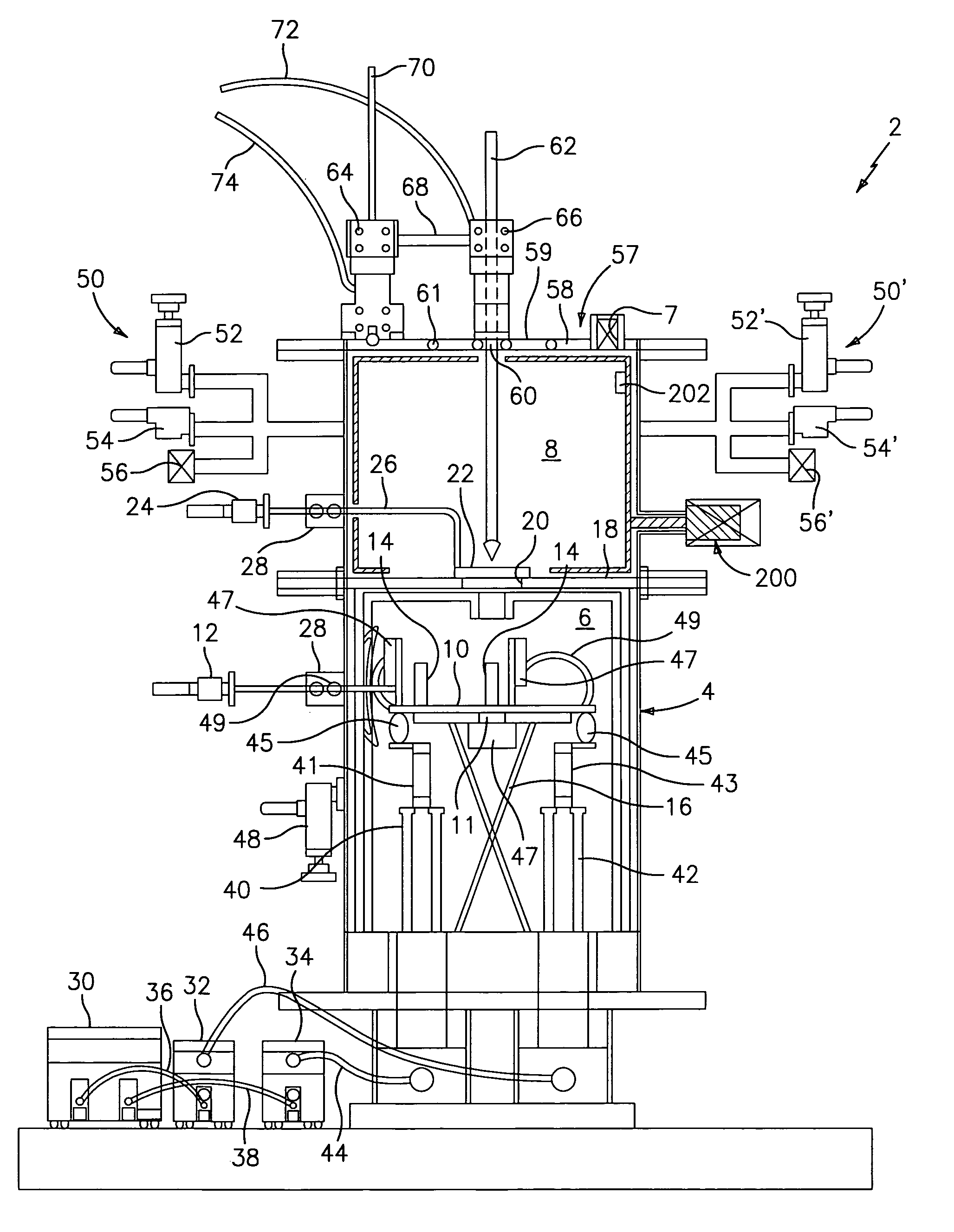

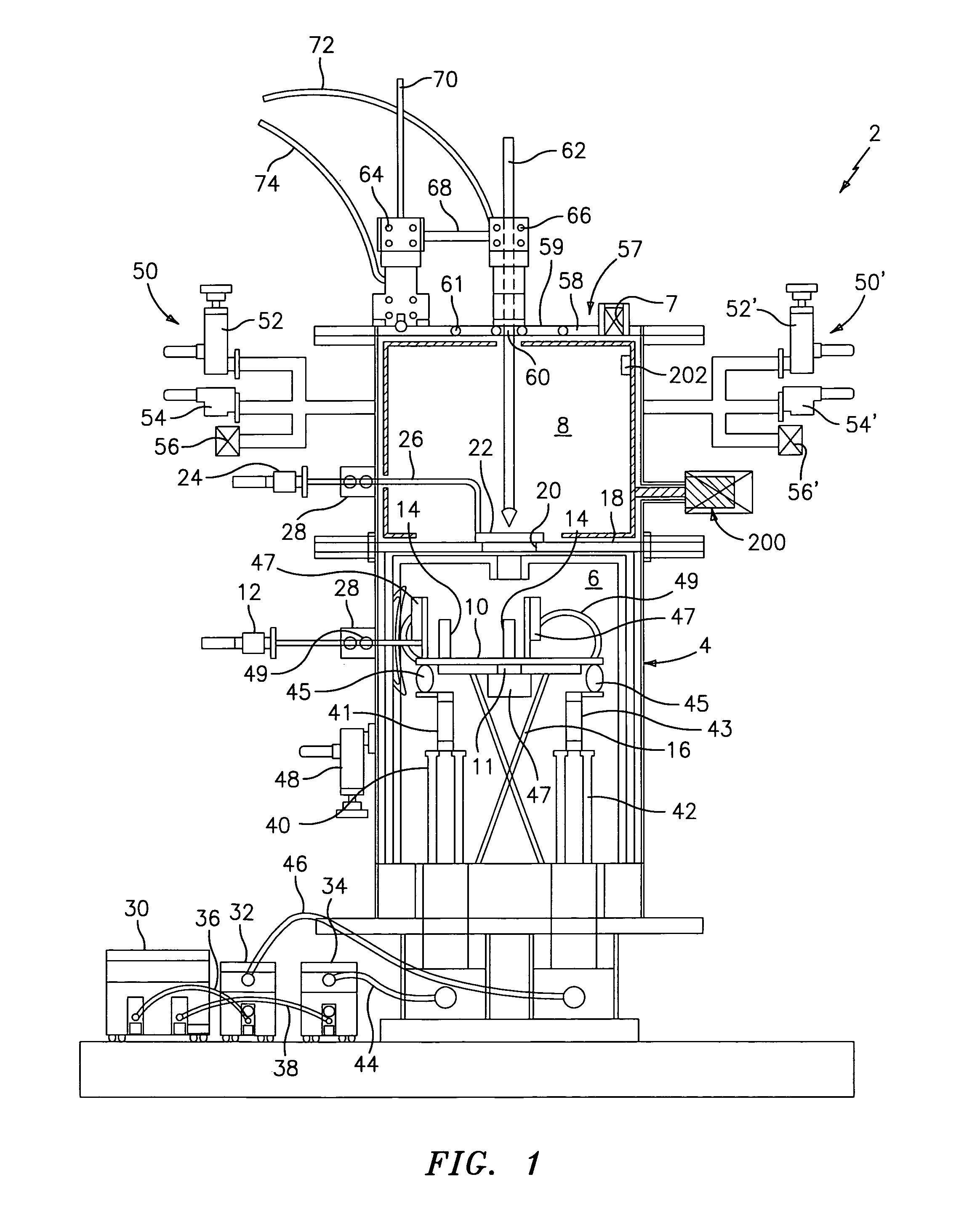

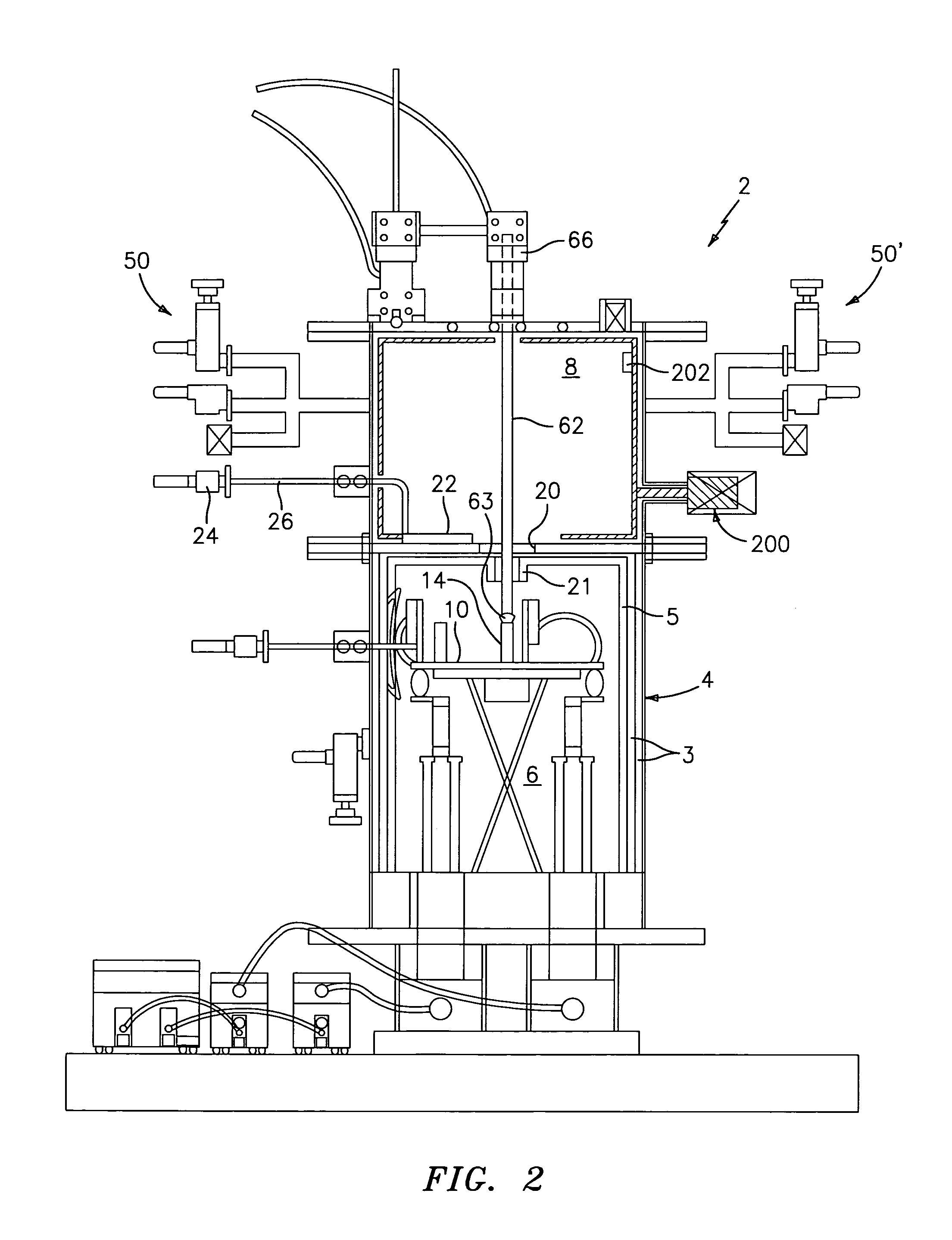

[0034]Referring now to the drawings, FIG. 1 shows a first embodiment of a cryo-preservation assembly, which is denoted generally by the numeral 2, and which is formed in accordance with this invention. The assembly 2 includes a housing 4 that has two chambers 6 and 8. The chamber 6 is a cooling chamber in which the specimen samples to be preserved are stored; and the chamber 8 is a specimen sample container retrieval chamber into which frozen samples are retrieved from the chamber 6. A pre-cooler 200 is used to pre-cool the upper chamber 8 after placing specimen samples in the upper chamber of the assembly 2; and a heater 202 is used to warm the upper chamber 8 prior to removing specimen samples from the upper chamber of the assembly 2. The cooling chamber 6 contains a movable specimen sample container stage 10 which is formed from a high thermally conductive material, such as copper, or the like. The stage 10 can be selectively moved by means of a stage actuator 12 which can transl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com