Method of using removable cleat system

a cleat system and cleat technology, applied in the direction of fastenings, fastening means, press-button fasteners, etc., can solve the problems of pressure against the socket, the use of screw-type attachment methods is especially laborious, and none of these systems have found wide acceptance among users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

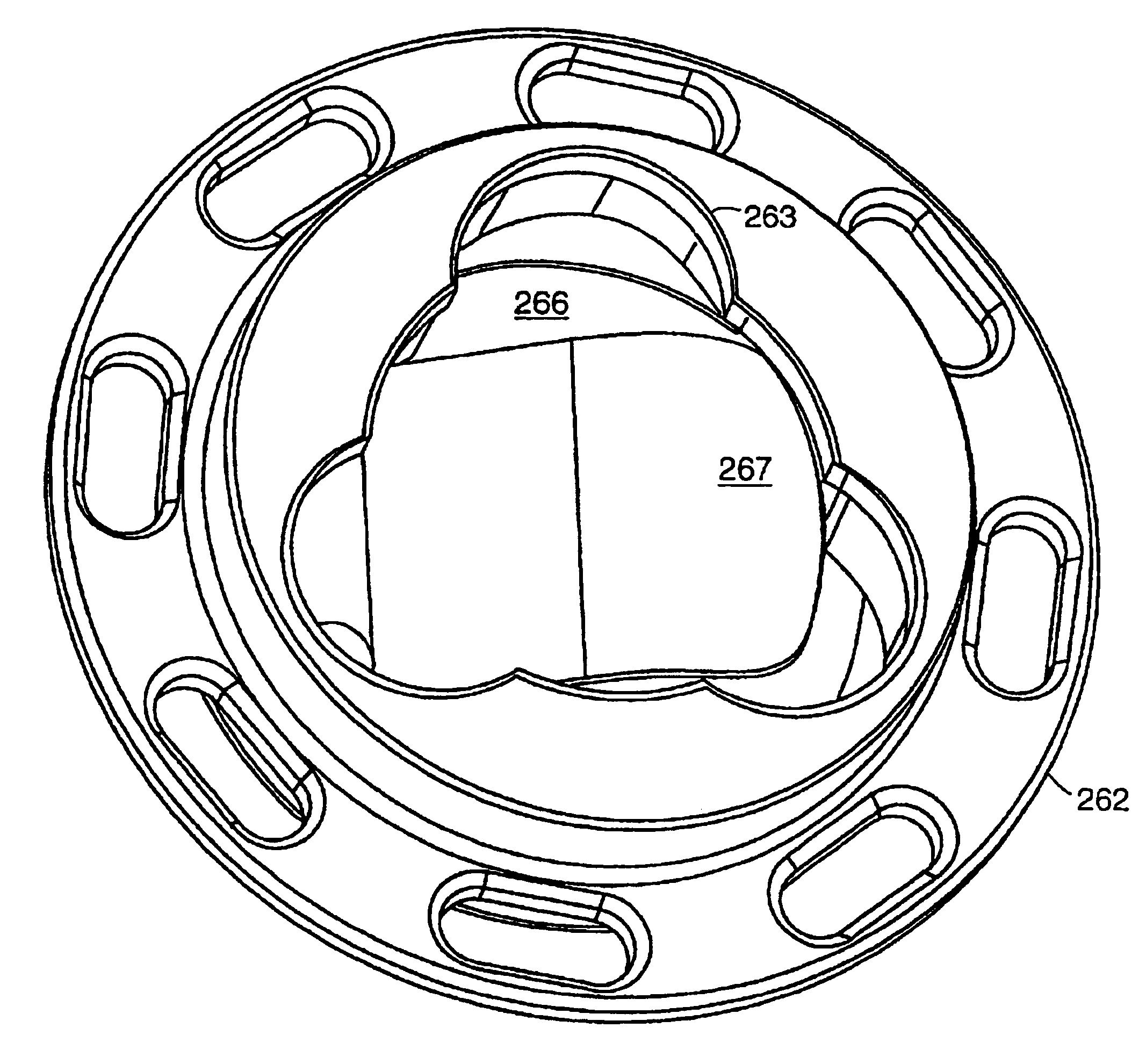

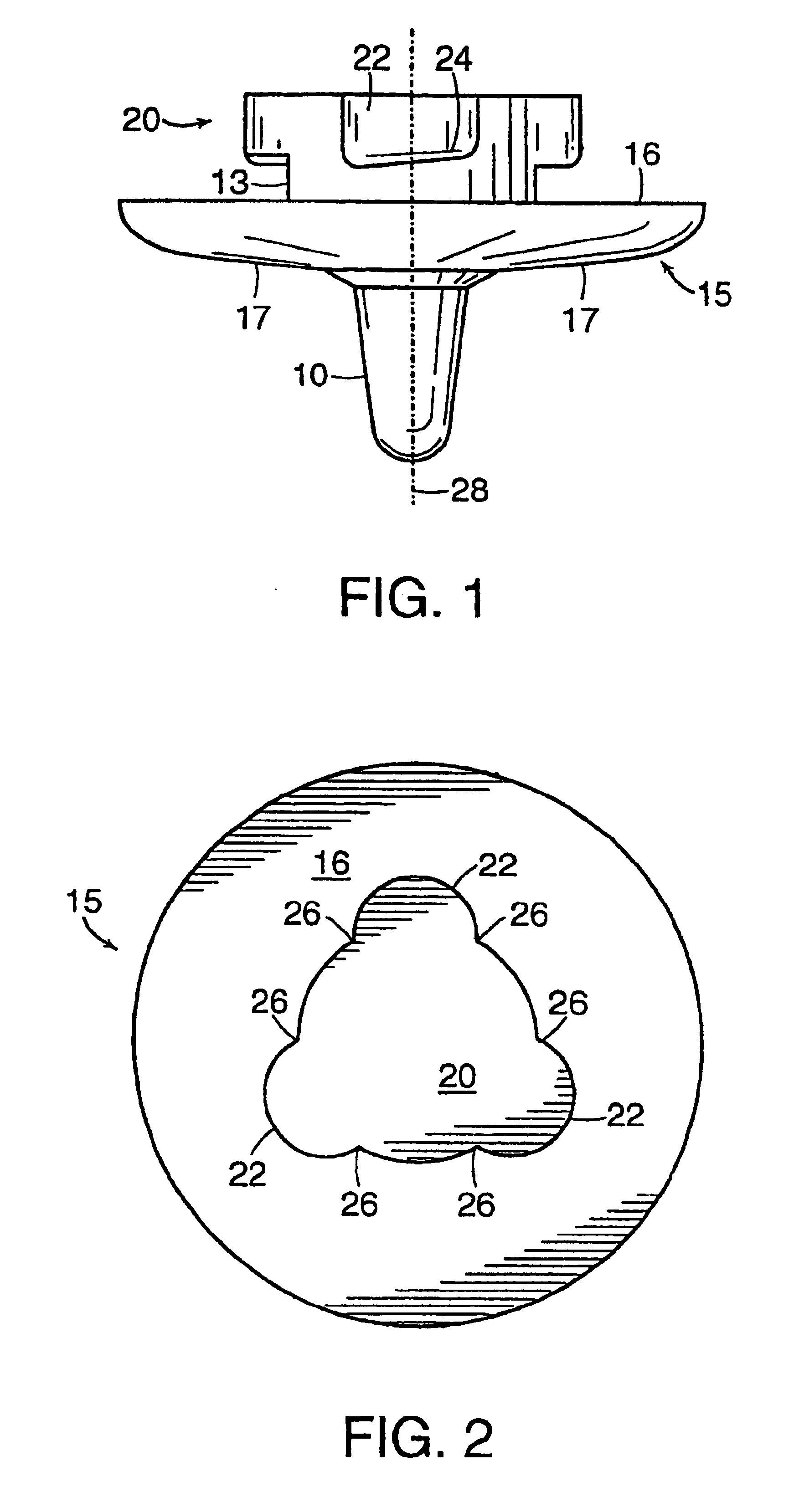

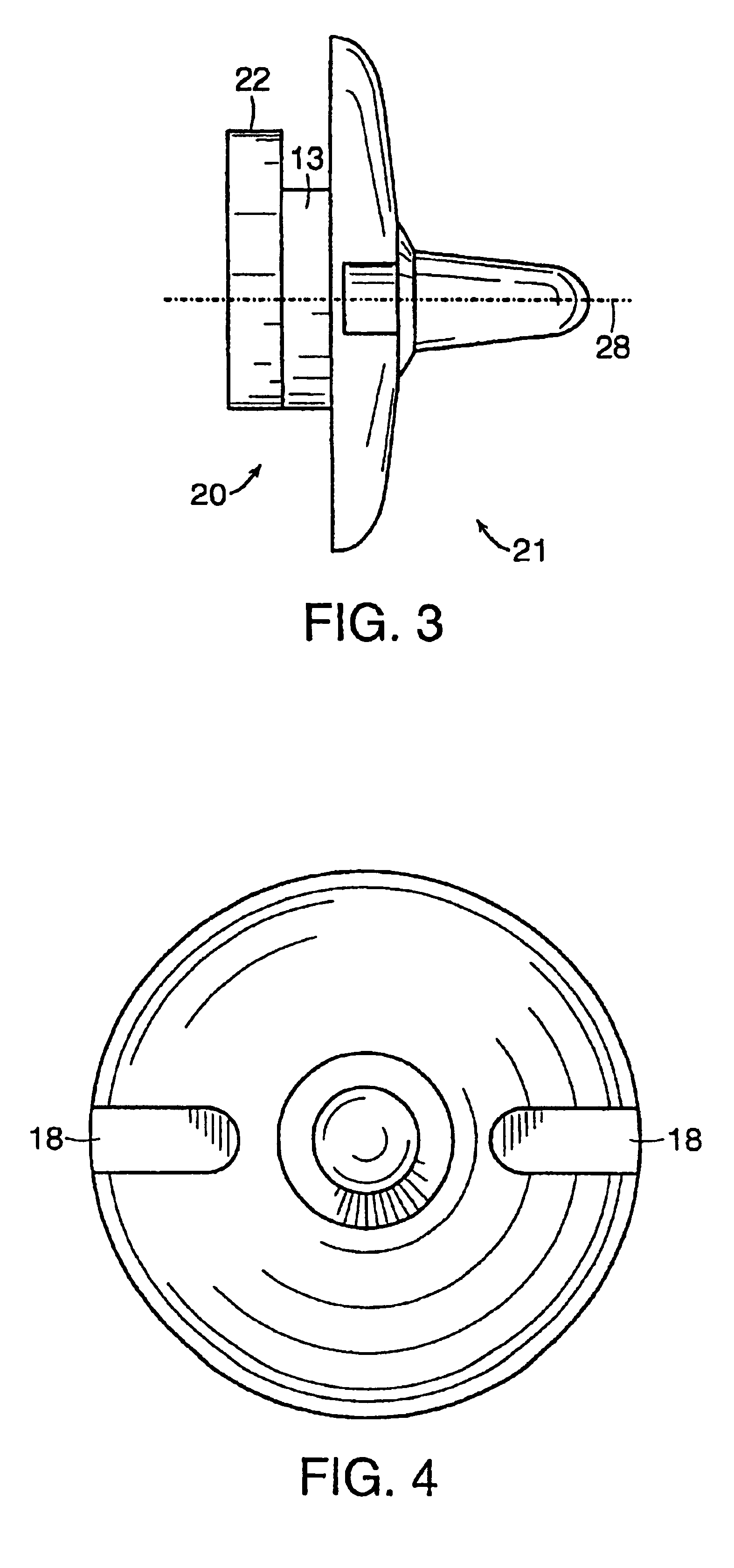

[0052]The invention comprises a system for allowing the quick attachment and release of a wide variety of traction gear. FIG. 1 shows that in one embodiment of the invention, the attachment system would be used to attach cleats, such as those disclosed in U.S. Pat. No. 4,723,366, to the underside of athletic footwear a cleat installed in the bottom of a shoe using the present invention, when viewed from the bottom, has a similar appearance to the preferred embodiment of the invention disclosed herein. Evident in FIG. 1 are the bottom side 17 and top side 16 of the plastic skirt 15, the ground-engaging head portion 10 of the cleat, a base 13 to which the plastic skirt and ground-engaging portion are attached and a retaining member 20, which in this case is a base 13 with three rounded extensions 22, all of which are positioned around a central axis 28. In a preferred embodiment of the invention, the top 16 of the skirt 15 is slightly concave, and the bottom 17 of the skirt 15 is some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com