Secondary cell, array and multi-layer array secondary cell having same

A secondary battery, array technology, used in secondary batteries, battery pack components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

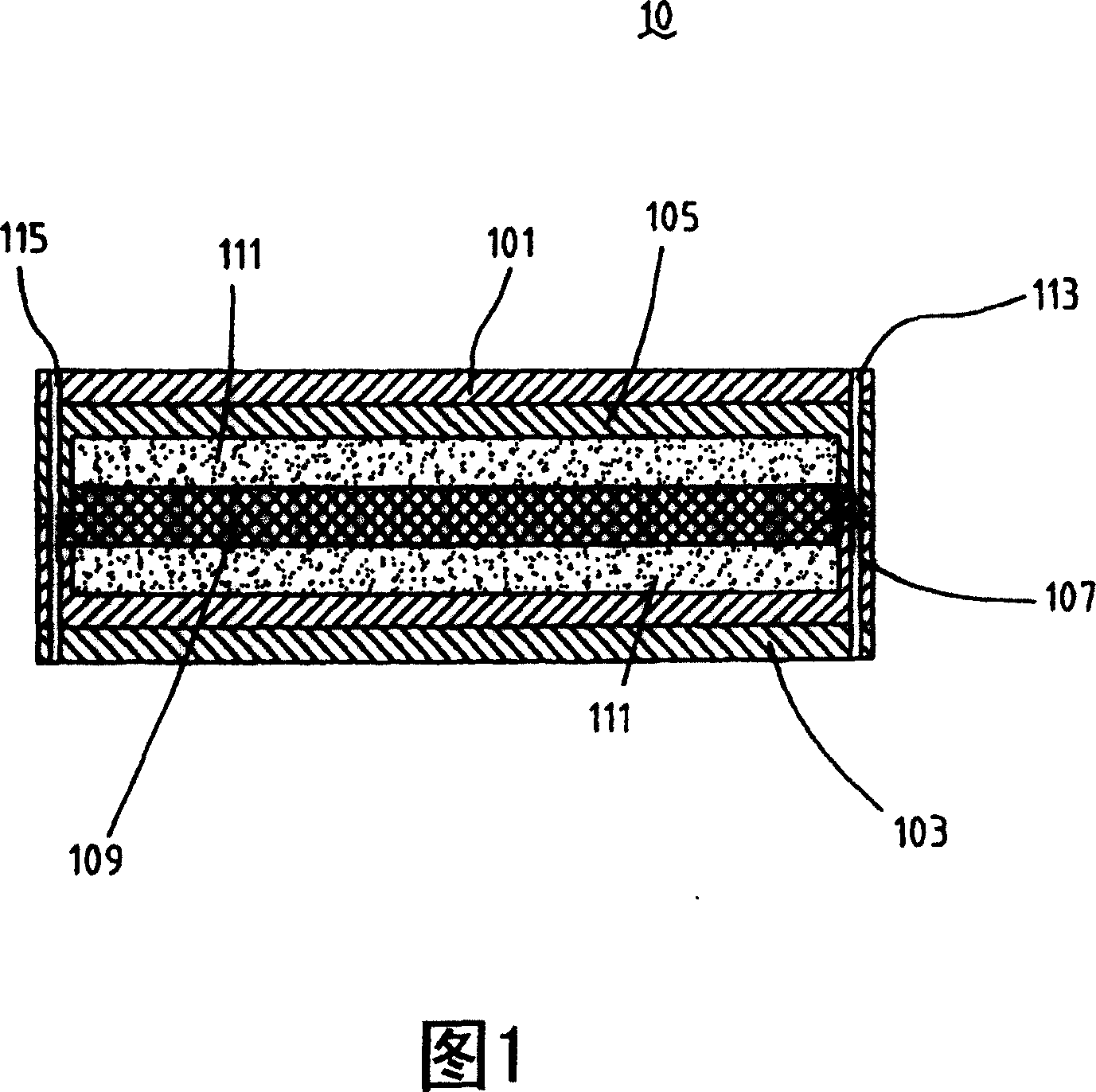

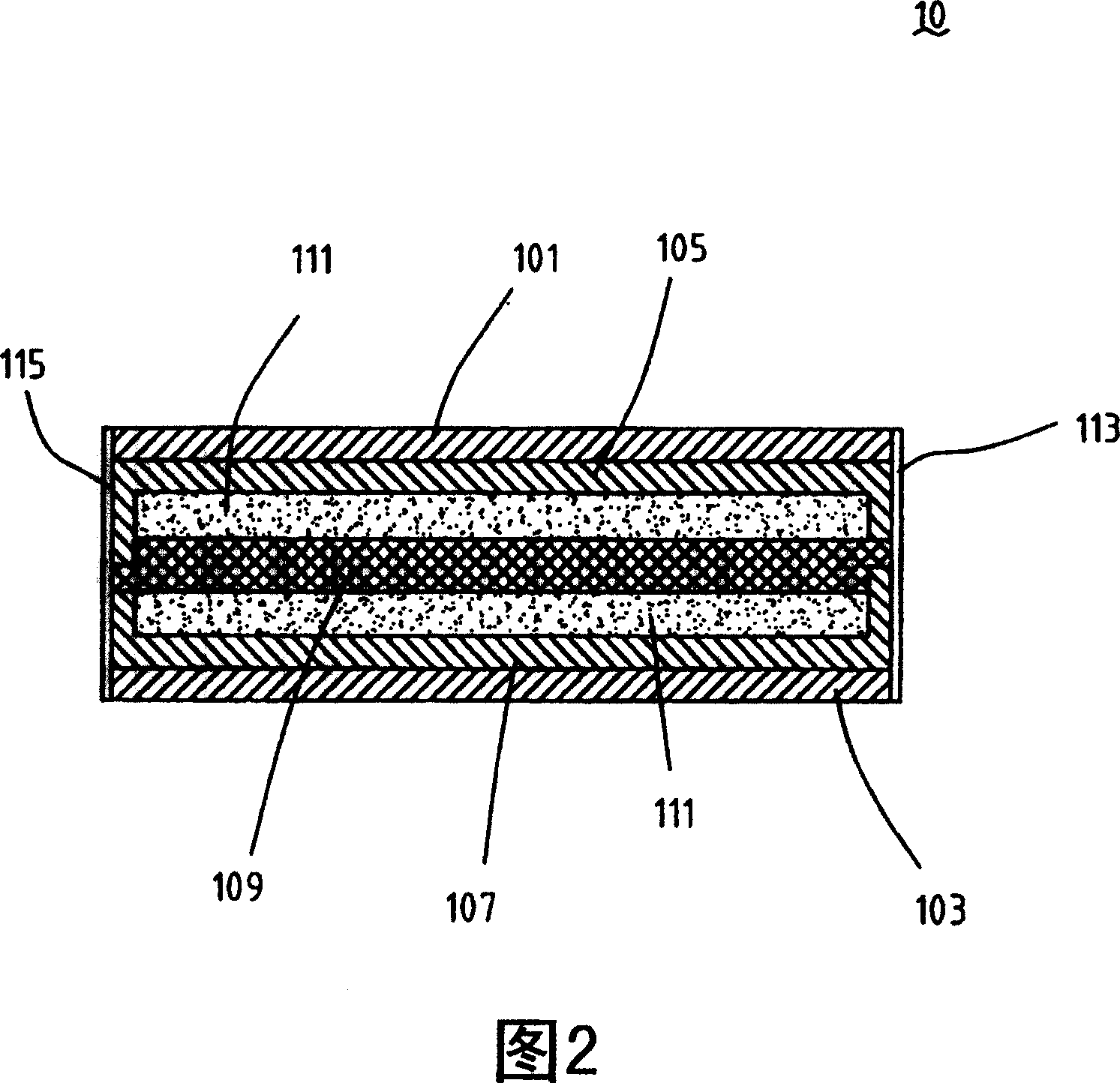

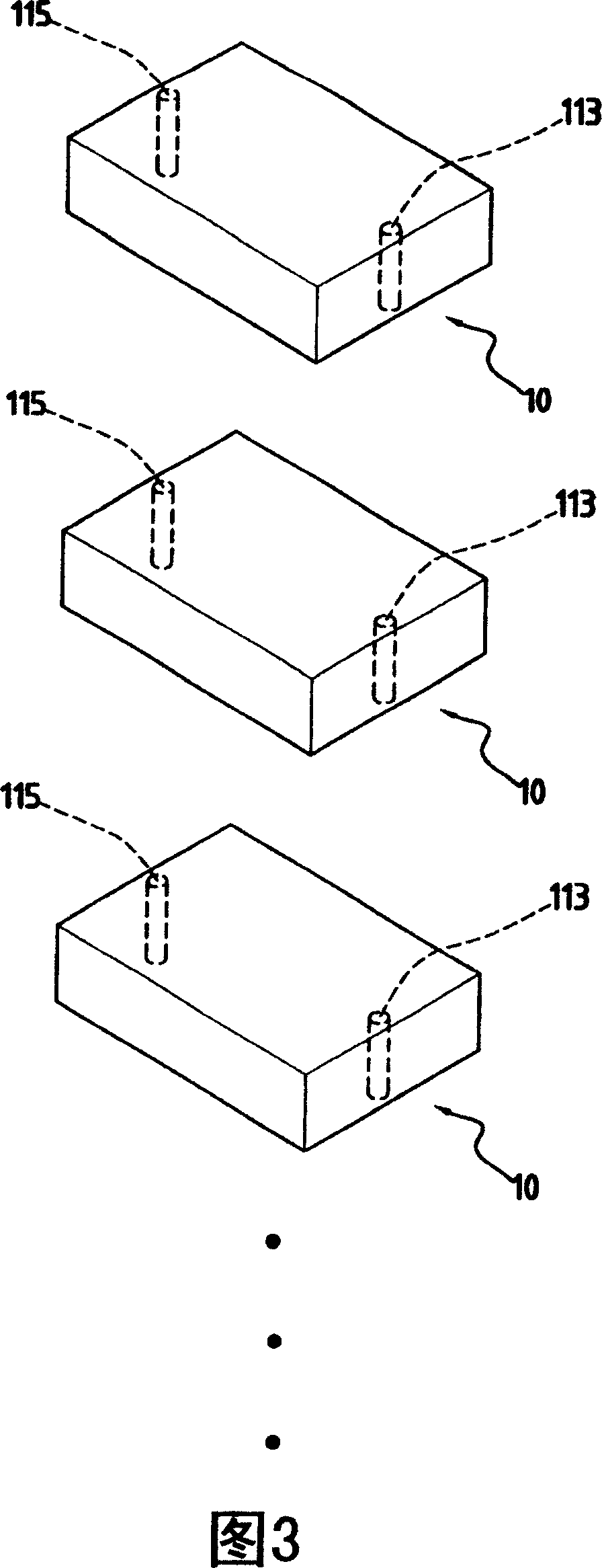

[0032] FIG. 1 shows a structural sectional view of a specific example of the secondary battery of the present invention, and FIG. 2 shows a structural sectional view of another specific example of the secondary battery of the present invention. The secondary battery 10 of the present invention mainly includes an upper housing 101, an upper housing tank 105, a secondary battery core assembly 109, a lower housing tank 107, and a lower housing 103, and these main components are stacked sequentially from top to bottom. stack into a tight structure. Except for the secondary battery core pack 109 , other components of the present invention are all made of printed circuit board material, and the used printed circuit board material may be FR4 material, for example. When assembling the secondary battery 10 of the present invention, the upper receiving tank 105 and the lower receiving tank 107 are used to accommodate the electrolytic substance 111, and the secondary battery core assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com