Holder of transportation facilities

A vehicle and grip technology, applied in steering mechanisms, bicycle accessories, transportation and packaging, etc., can solve the problems of cumbersome and laborious assembly operations, inability to disassemble and replace by oneself, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

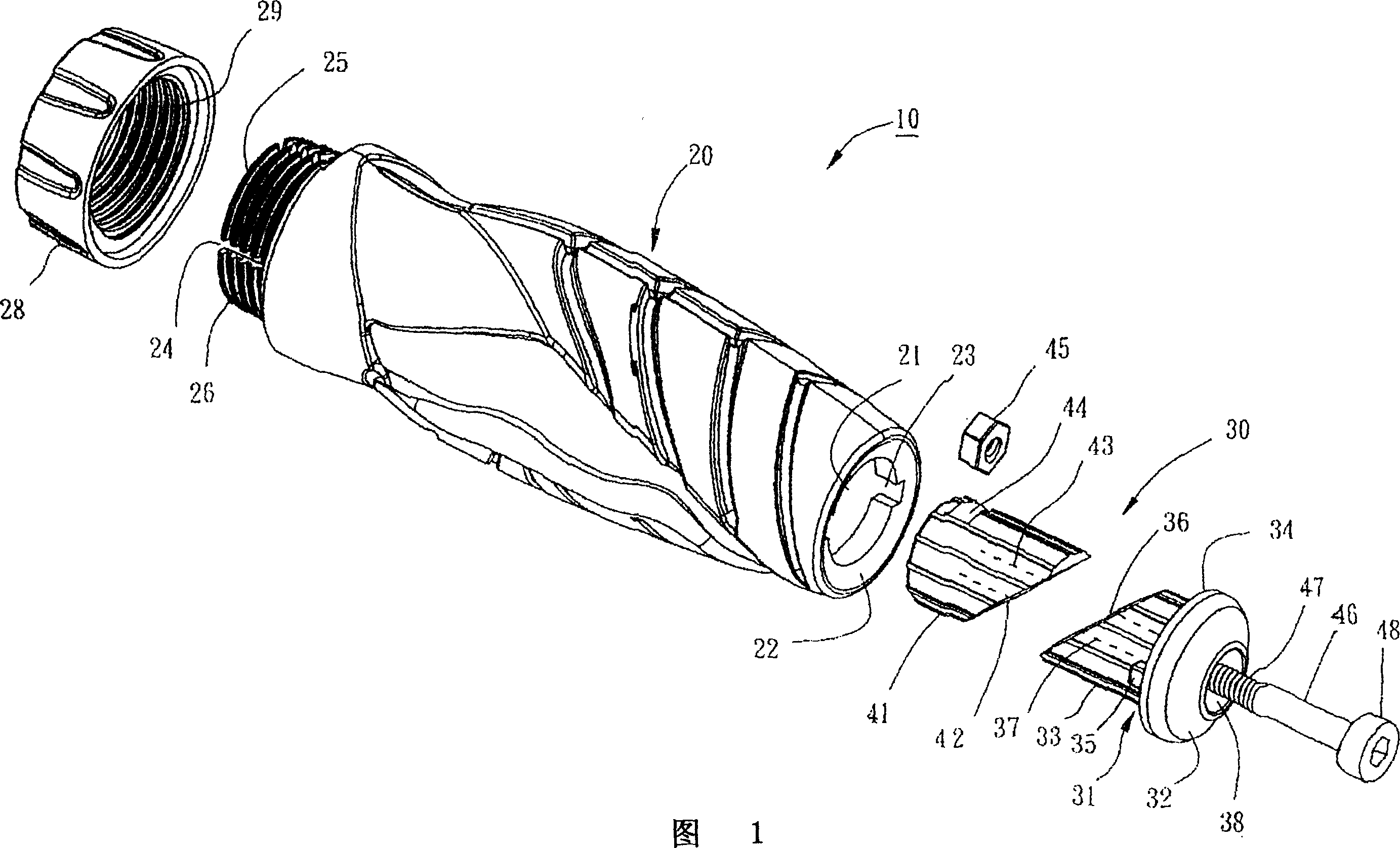

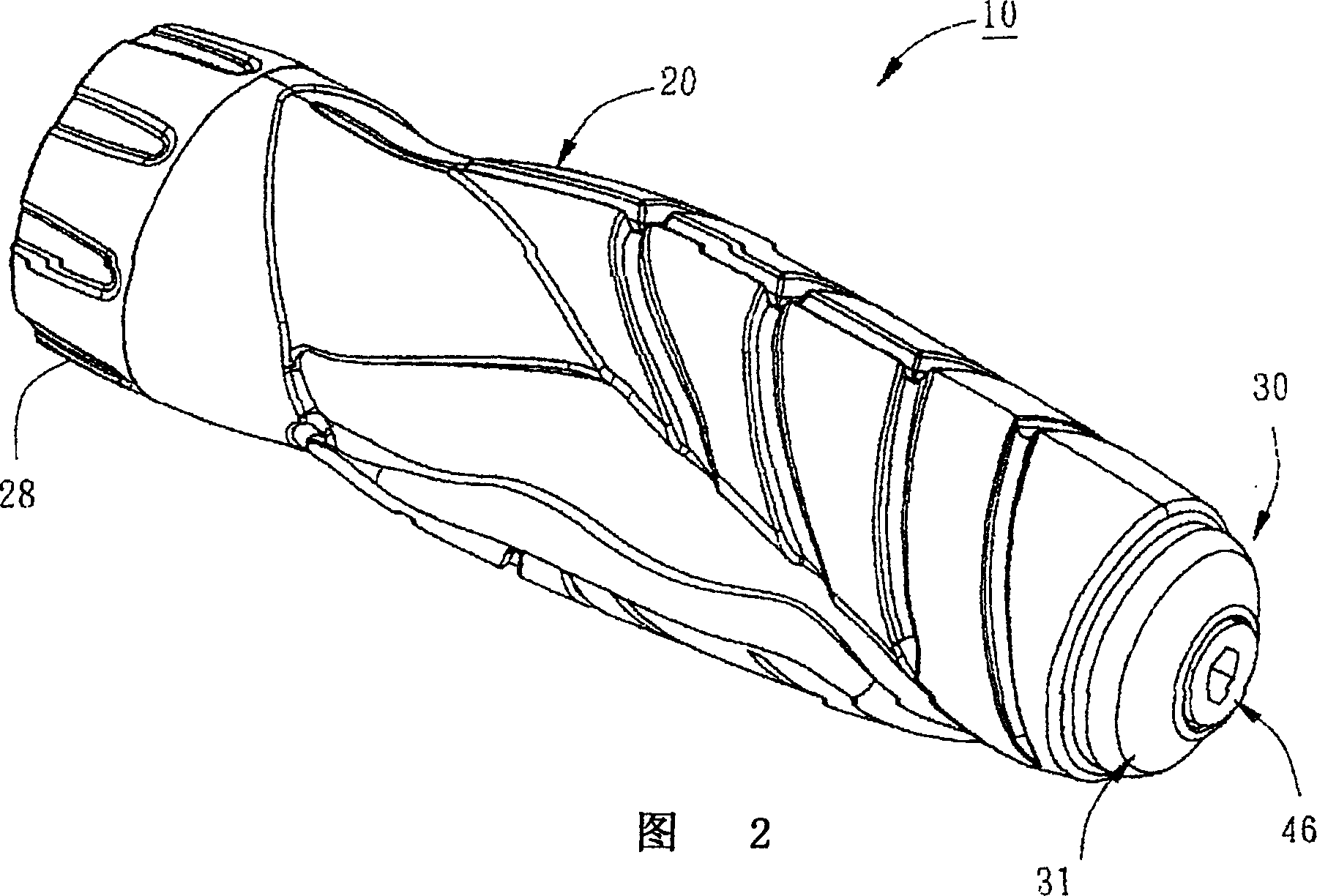

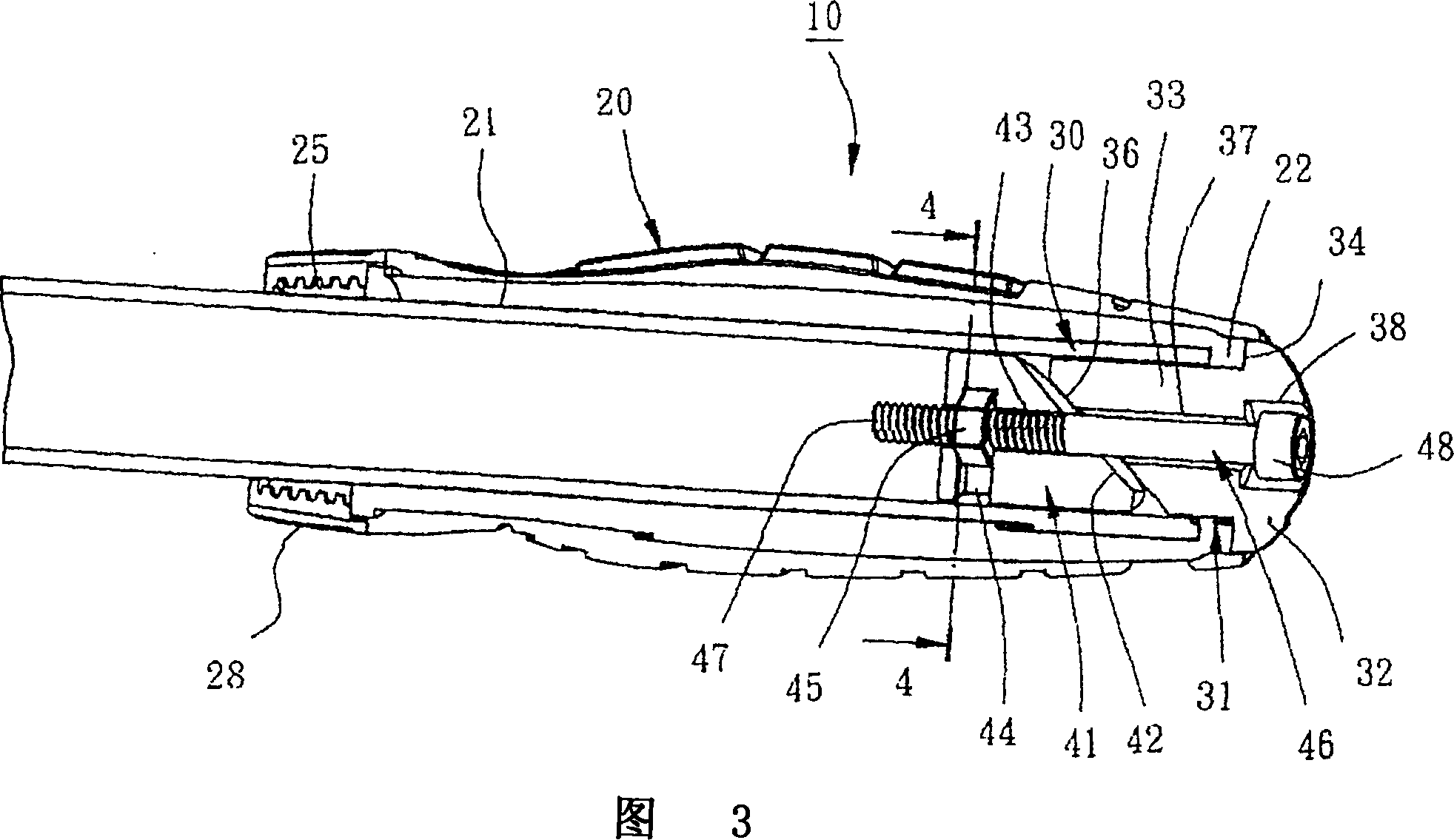

[0014] As shown in Figures 1 to 3, the handle 10 provided by the first preferred embodiment of the present invention is generally composed of a sleeve 20, a bundle ring 28 and a tightening device 30, wherein:

[0015] The sleeve 20 has a straight circular tube hole 21 whose diameter corresponds to the outer diameter of the handle tube of the vehicle to be used, so that the sleeve 20 can be sleeved on the handle tube. The first end (the right end in the figure) of the sleeve pipe 20 is provided with an inner convex ring 22 protruding from the wall of the tube hole 21 toward the axial center, and the diameter of the inner edge of the inner convex ring 22 roughly corresponds to the inner diameter of the aforementioned handle pipe; The protruding ring 22 is provided with two embedded grooves 23 with opposite openings. The second end (the left end in the figure) of the casing 20 has four slits 24 extending axially inward from the edge of the casing, and the four slits 24 are distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com