Assembling structure of cabinet

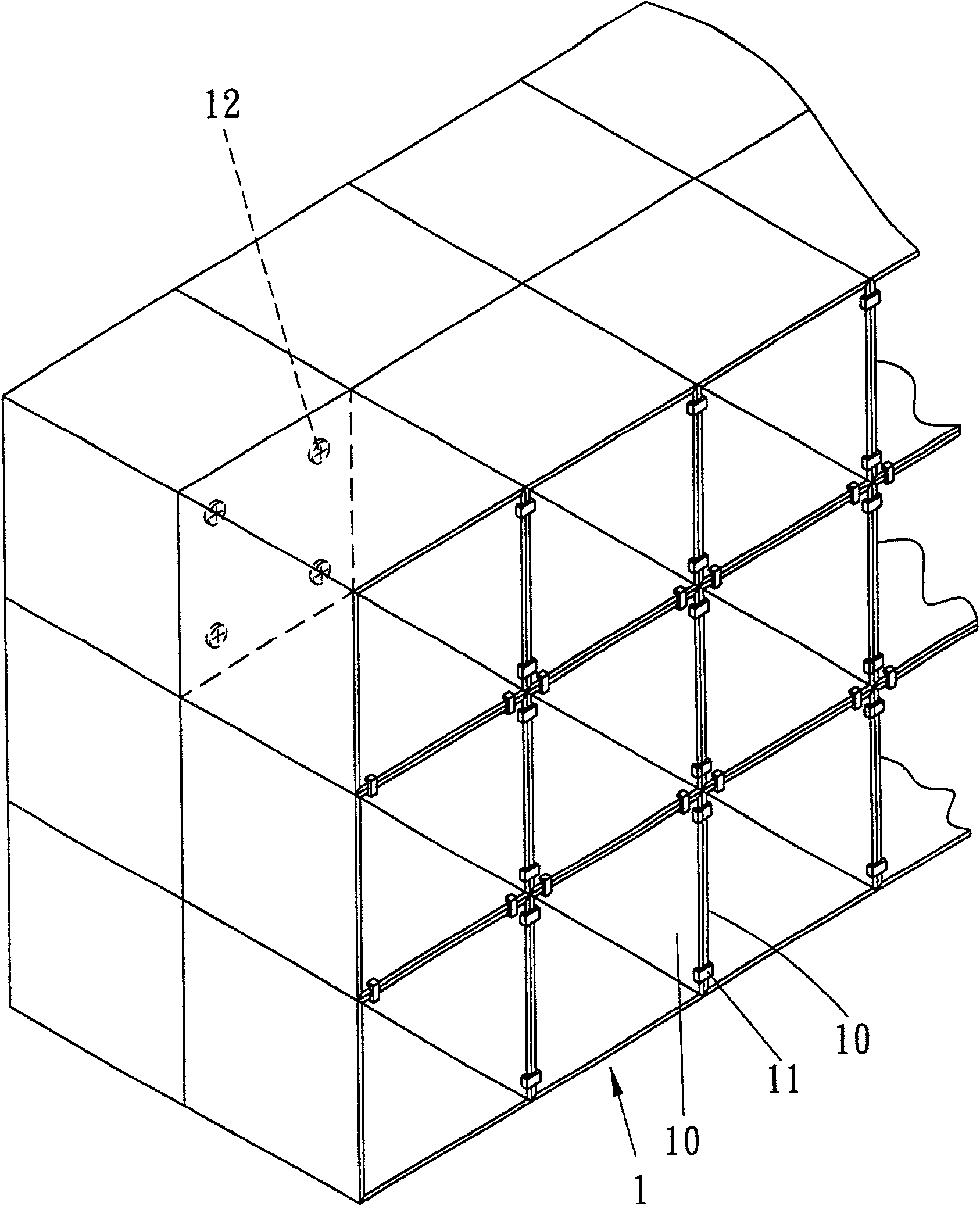

A combined structure and cabinet technology, applied in combined furniture, home appliances, applications, etc., can solve the problems of cabinet 1 falling, lockers cannot be set stably, time-consuming, etc., and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred and feasible embodiment hereby, and cooperates as shown in the accompanying drawings, explains in detail as follows:

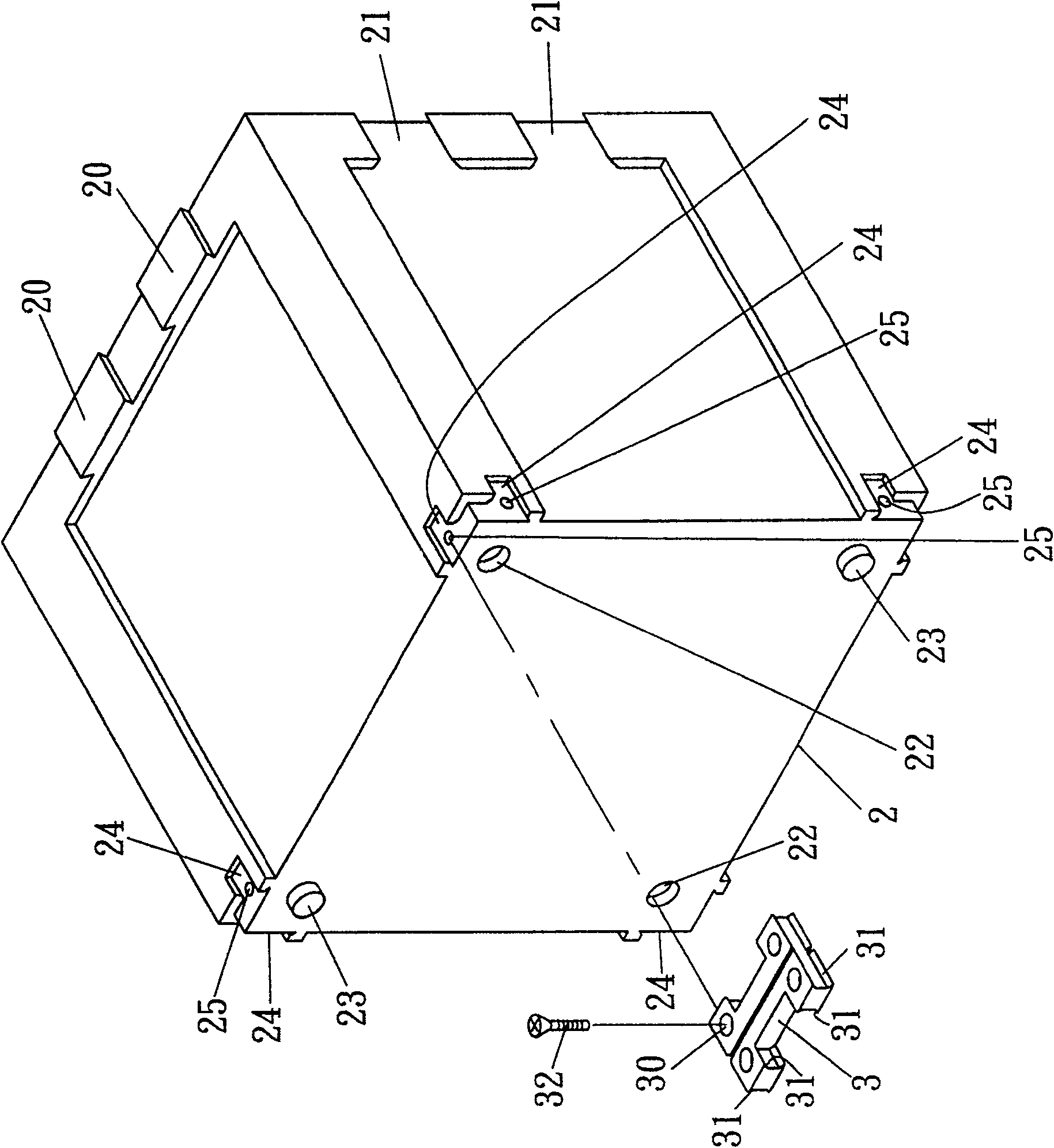

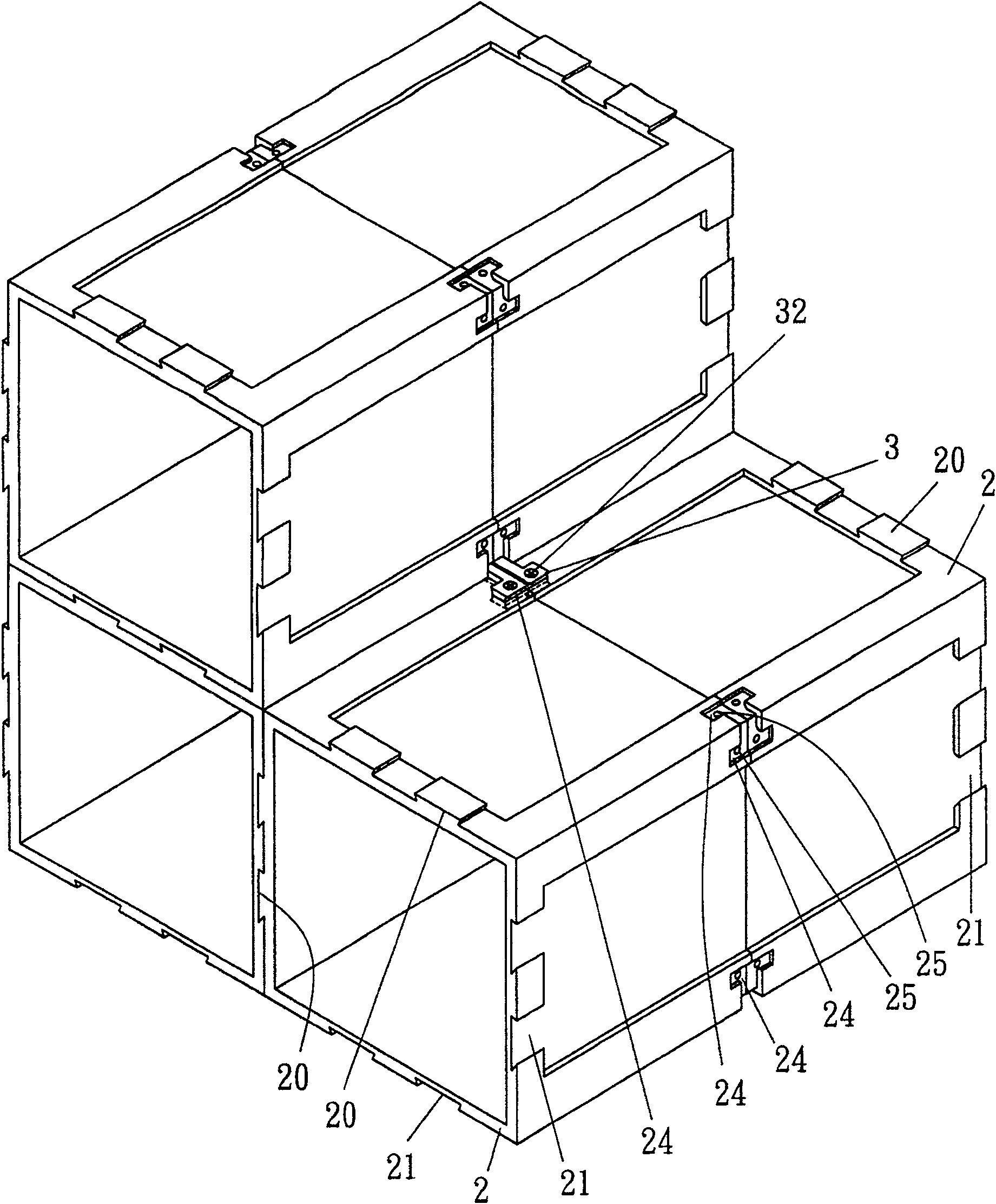

[0014] First, see figure 2 , image 3 As shown, two dovetail seats 20 are protruded on the adjacent two peripheral walls of the cabinet body 2, and two dovetail grooves 21 are formed on the other adjacent two peripheral walls. There are perforations 22 and protruding columns 23, and an L-shaped dovetail groove-shaped inlay 24 is respectively provided on two adjacent planes on the rear end corner of the cabinet body 2, and a screw hole 25 is provided in the inlay 24; The latch 3 is inserted at the rear end of the cabinet body 2, the positioning latch 3 is I-shaped, and each of its four ends is provided with a perforation 30, and the top and bottom surfaces of the four ends of the positioning latch 3 are convexly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com