Door mirror

A technology for door mirrors and side doors, which is applied in the field of door mirrors, and can solve problems such as adding components and increasing the number of assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

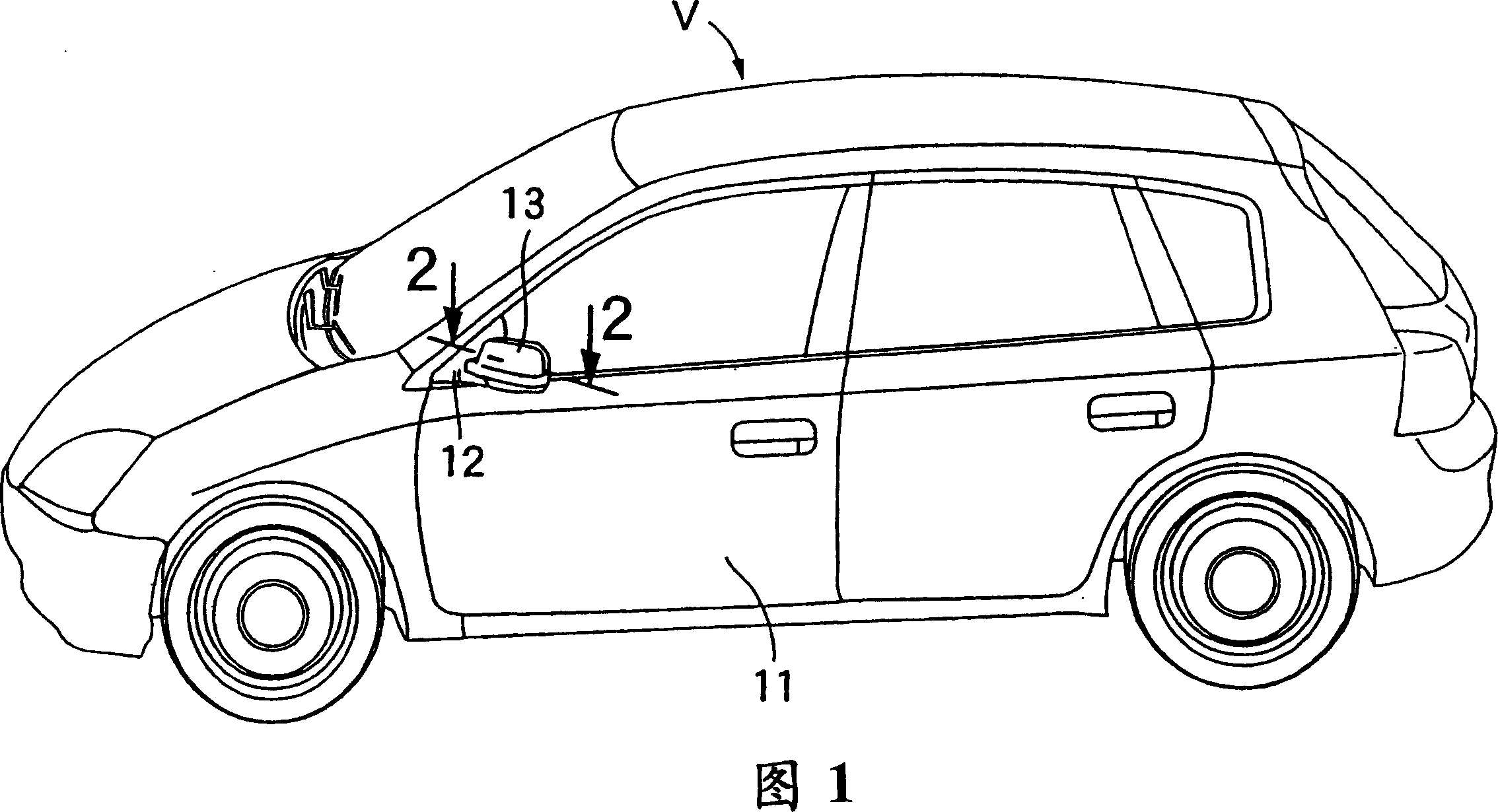

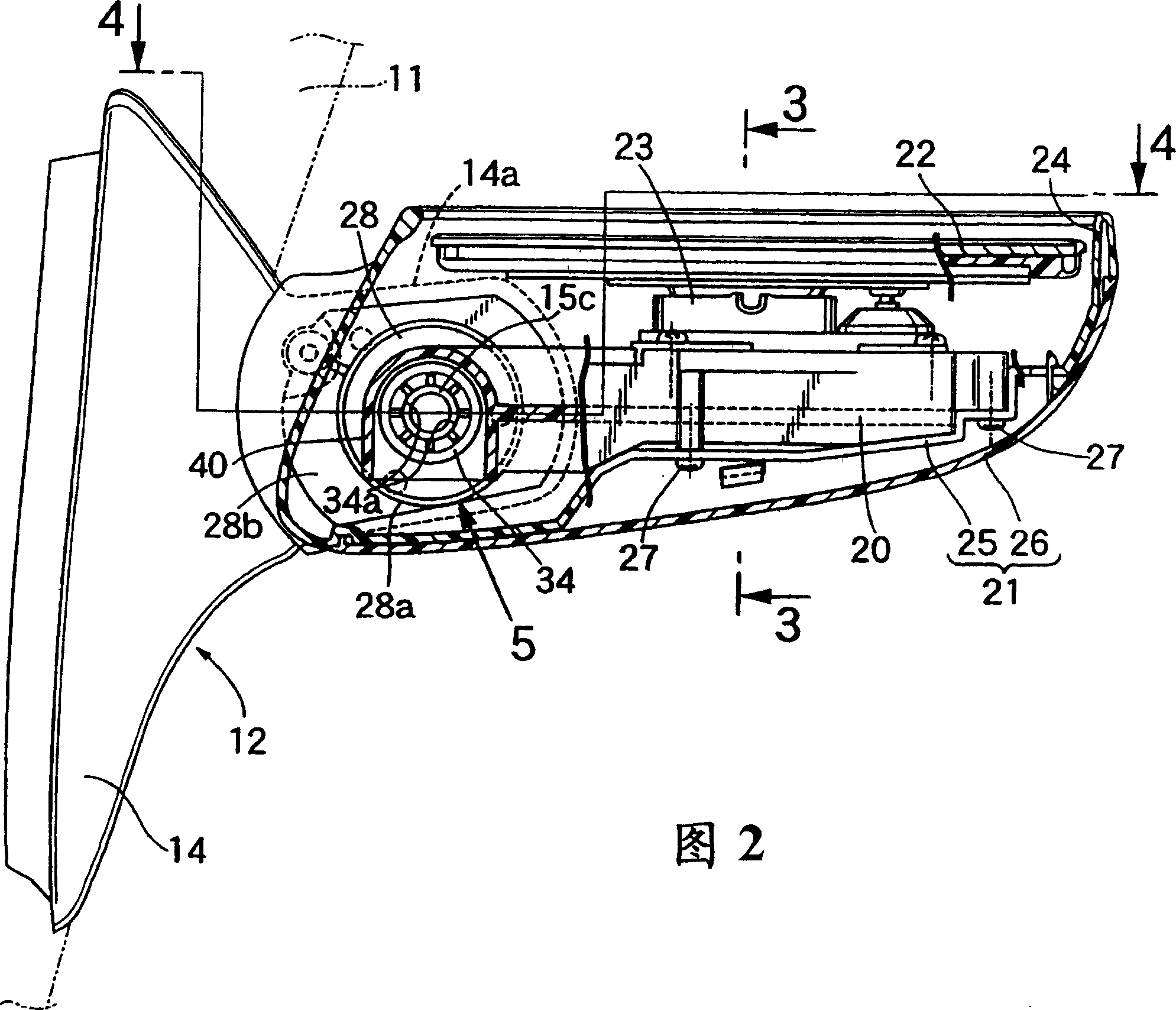

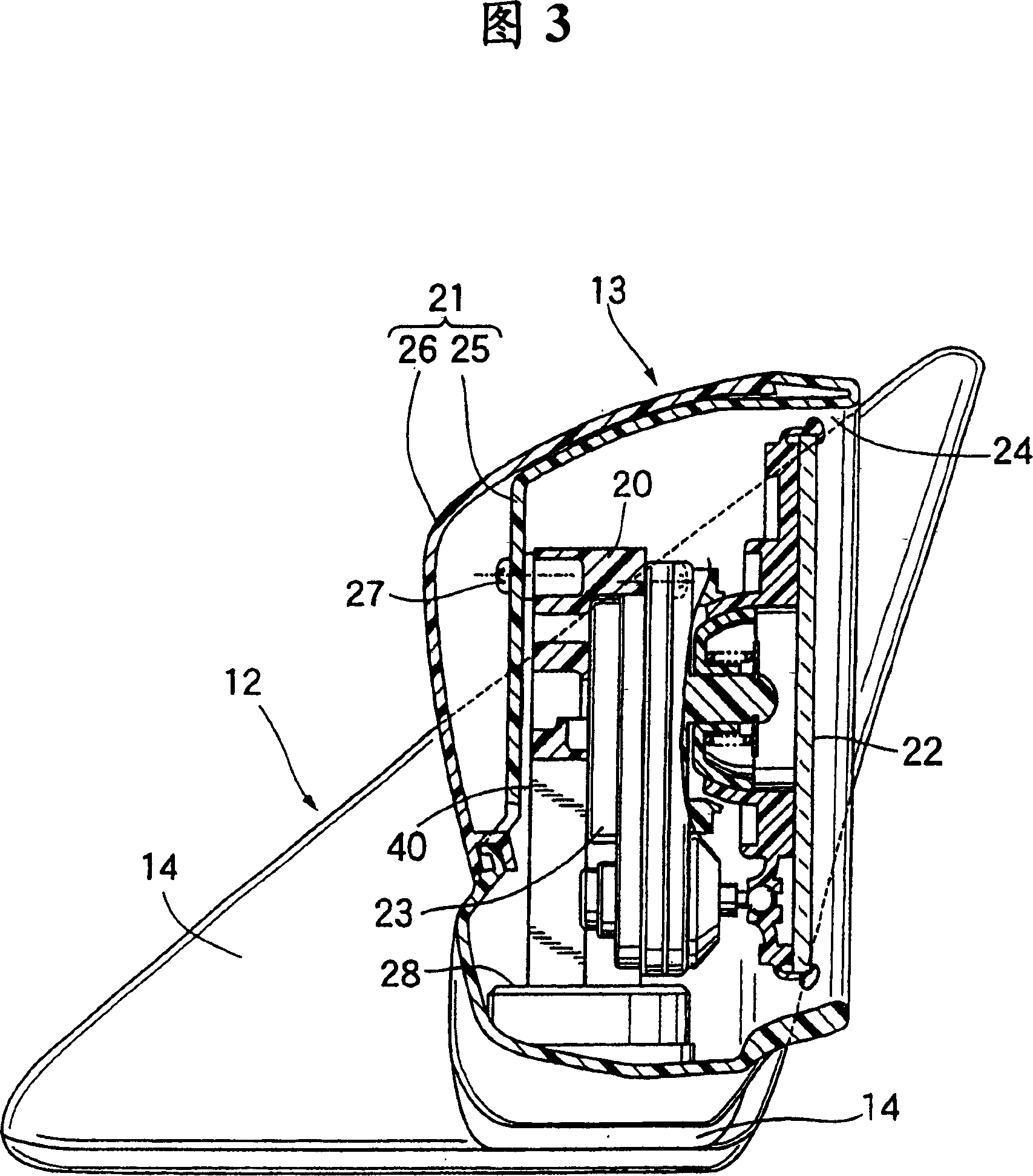

[0024] 1 to 6 show an embodiment of the present invention.

[0025] In FIG. 1 , a base 12 is attached to a side door 11 of a passenger vehicle V, and a mirror body portion 13 is rotatably supported on the base 12 so that it can rotate relative to the passenger vehicle V front and rear.

[0026] 1 to 4, the base 12 includes: a base member 14 made of synthetic resin and attached to the side door 11, which has a support arm 14a protruding from the side door 11; and a metal support attached to the base member 14 piece 15.

[0027] An opening 16 is formed on the top of the support arm 14a, and the support member 15 includes a flat piece 15a that is located at the opening 16 and forms an upward support seat 17, a substantially closed cylindrical support that is lifted upwards from the support seat 17. The column body 15b, and the cylindrical support shaft 15c, which is smaller in diameter than the support column body 15b and raised upward from the center portion of the closed top e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com