Blower

An air supply device and fan technology, which is applied to pump devices, components of pumping devices for elastic fluids, ventilation systems, etc., can solve problems such as inability to blow off, inability to supply air, and complicated operations, and reduce regular maintenance. The number of times, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

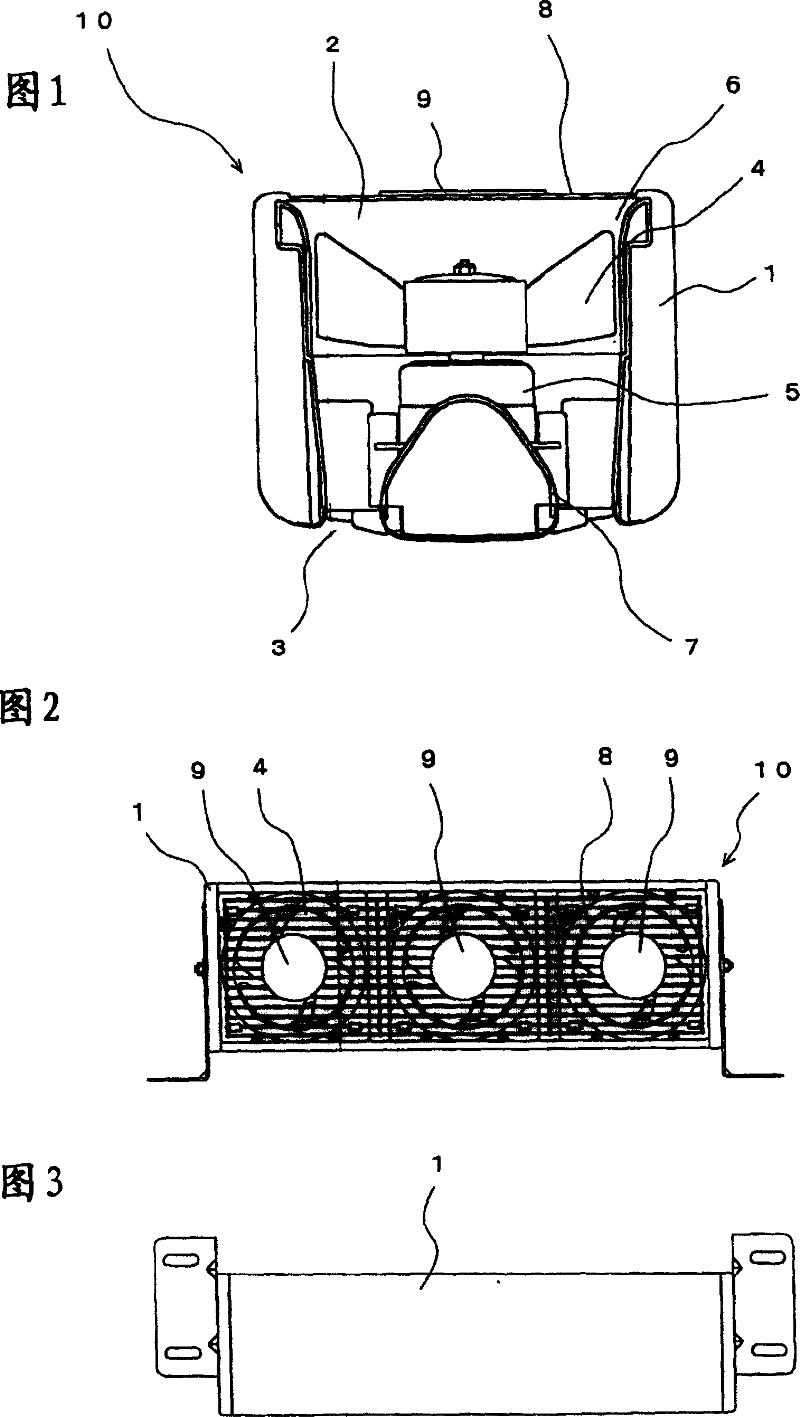

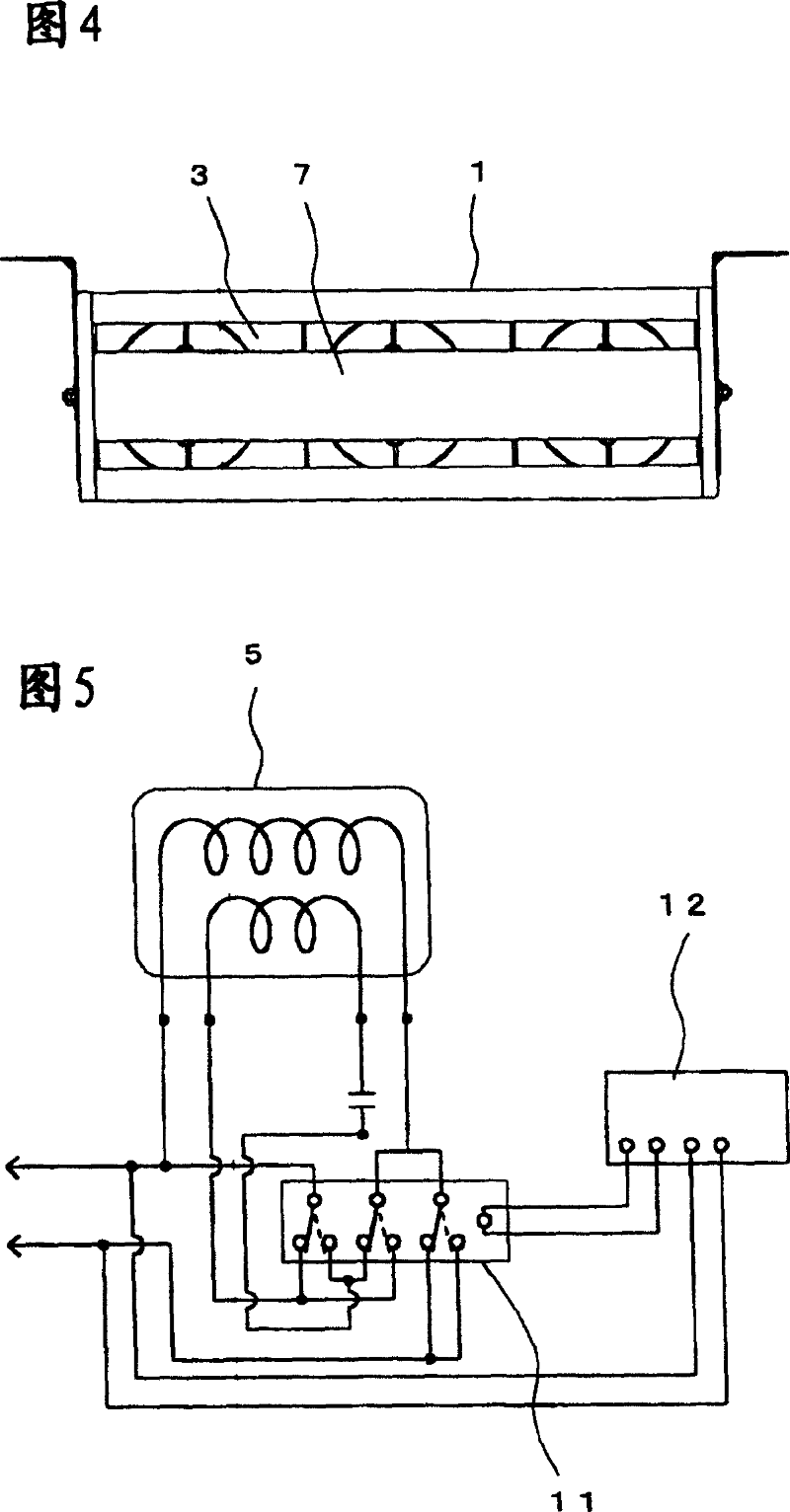

[0023] 1 is a cross-sectional view showing the internal structure of an air blower according to Embodiment 1 of the present invention, FIG. 2 is a rear view of an air blower equipped with, for example, three blowers of FIG. 1 , FIG. 3 is a top view of FIG. 2 , and FIG. Figure 2 Front view. FIG. 5 is a circuit diagram of this embodiment.

[0024] The air blower 10 is used for indoor air blowing or equipment cooling, and is installed in a state of being suspended, ground-mounted, or wall-mounted. The air blower 10 has a main body 1 in the shape of a six-sided box. The main body 1 is provided with an air inlet 2 at the back and an air outlet 3 at the front. In addition, the inside of the main body housing 1 is partitioned according to the number of air blowers. FIG. 1 shows one air blower, and FIG. 2 shows three air blowers. Moreover, each air blower inside the main body casing 1 is equipped with an axial flow fan 4 and a motor 5, and the axial flow fan is arranged in the insid...

Embodiment approach 2

[0033] In this embodiment, in the aspect of Embodiment 1, the timer switch 12 is used to make the air blower reversely operate only for a certain period of time at the start of the operation to perform cleaning. According to this, even if the power supply is turned off outside the operating hours, it is possible to clean the filter or the protective cover 8 .

Embodiment approach 3

[0035] In this embodiment, in the aspect of Embodiment 1, the timer switch 12 is used to make the air blower reversely run only for a certain period of time when the operation is finished, and to perform cleaning. According to this, even if the power supply is turned off outside the operating hours, it is possible to clean the filter or the protective cover 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com