Dying still in supercritical CO2 dyeing device

A carbon dioxide and dyeing device technology, applied in the field of dyeing devices, can solve the problems of relying on static dyeing and poor level dyeing, and achieve the effect of solving uneven static dyeing, ensuring the effect, and high level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

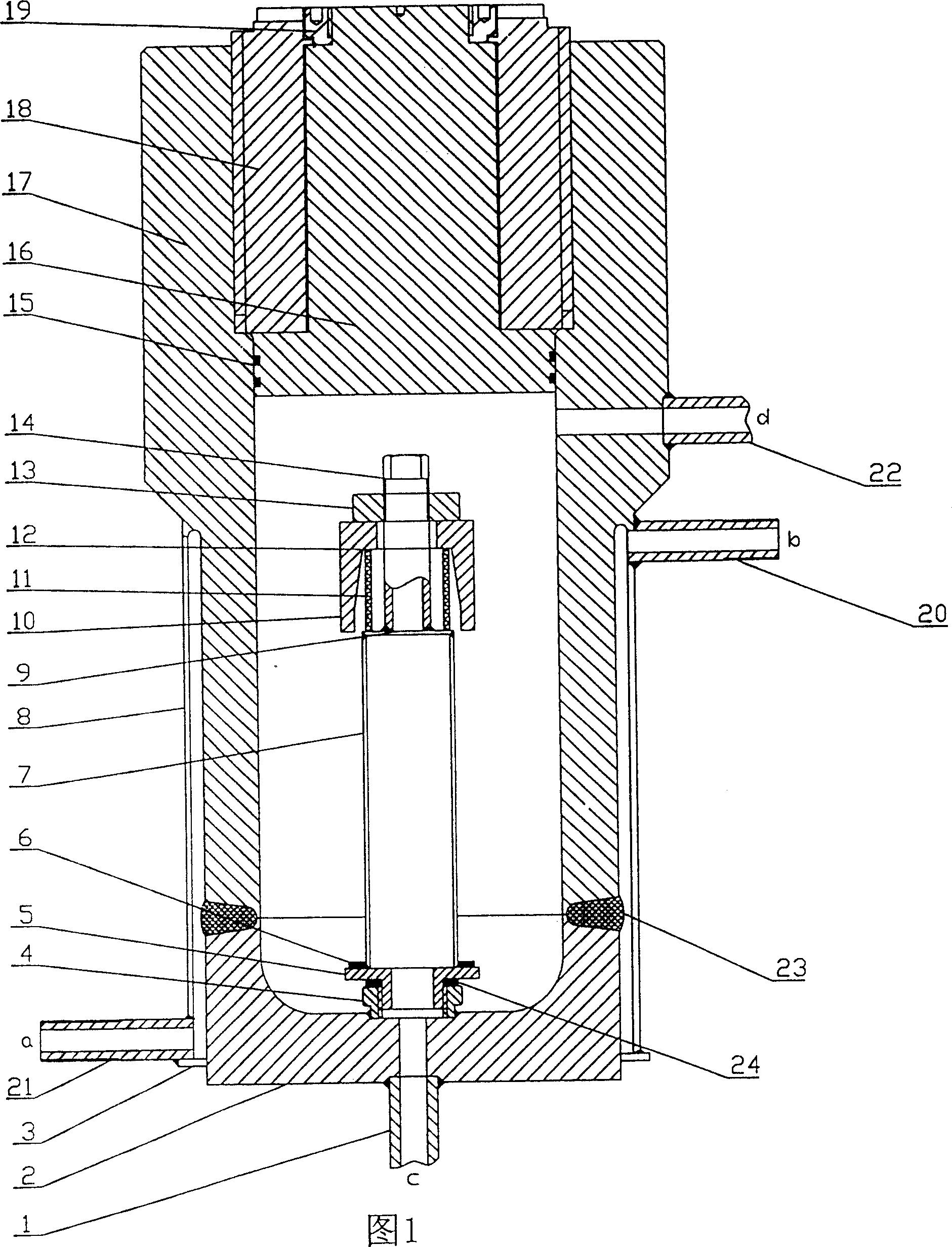

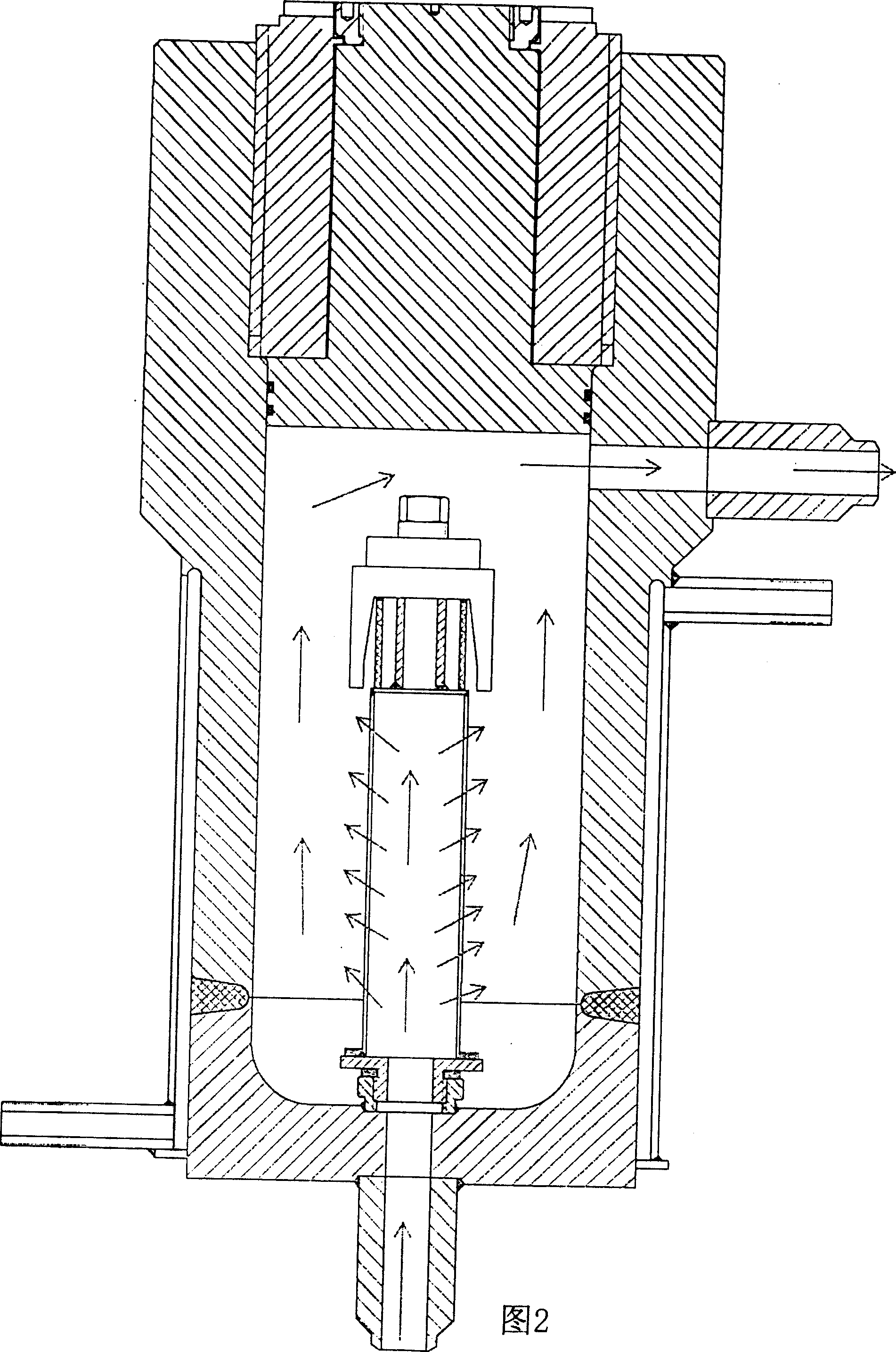

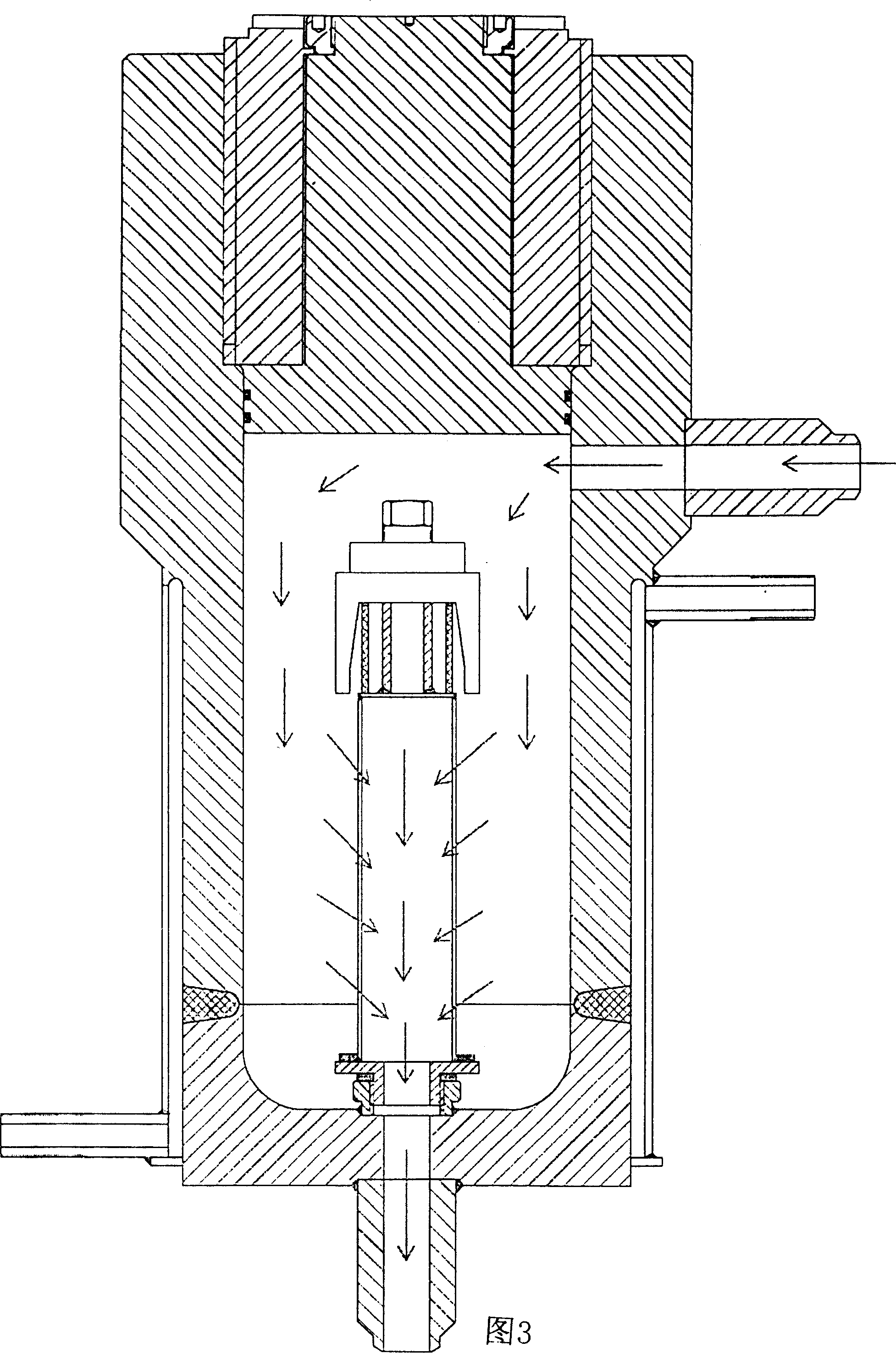

[0017] The structural representation of the dyeing still in the supercritical carbon dioxide dyeing device of the present invention as shown in Fig. 2 The process of dyeing in contact with textiles. The structure of the dyeing kettle includes a material cylinder 17 with a closed bottom and a shouldered flat cover 16 arranged on the top of the cylinder 17. The shouldered flat cover 16 can be disassembled and needs to be fixed and sealed during work. The top of the shoulder flat cover 16 is threadedly connected to the threaded sleeve 18, and the threaded sleeve 18 is threaded to the upper part of the cylinder body 17, and the upper end of the threaded sleeve 18 is fixed with a positioning nut 19; An O-ring 15 is provided. Wherein, the threaded sleeve 18 is used to fix the shoulder flat cover 16 and achieve multi-layer sealing through the O-ring 15 . Because in the supercritical carbon dioxide dyeing process, higher pressure is required, so the sealing performance in the dyeing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com