Paper width detector

A detection device, paper technology, applied in the direction of printing device, printing, etc., can solve the problems of increased cost, complex judgment mechanism, and inability to detect the width of non-standard paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

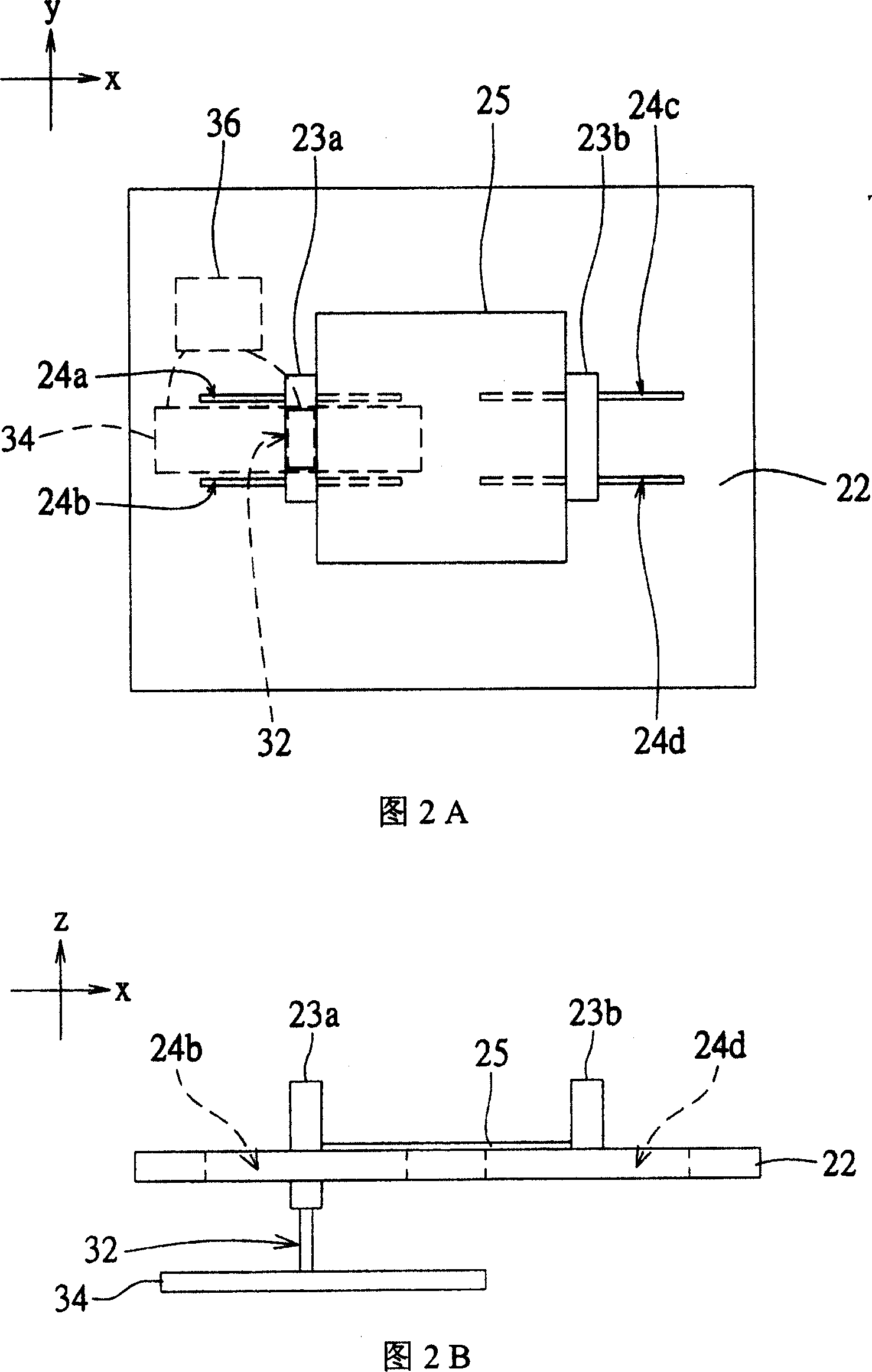

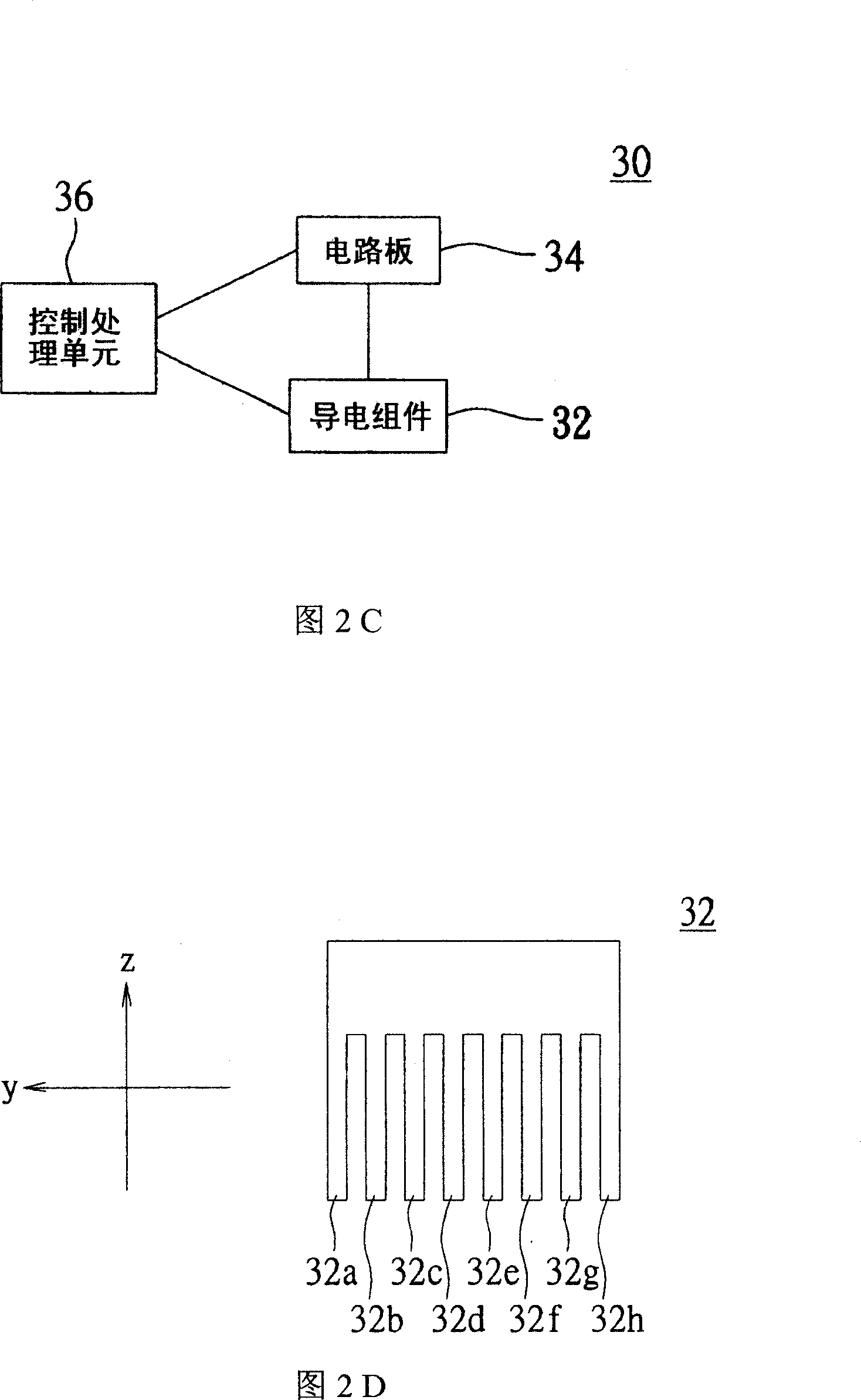

[0021] Please refer to FIGS. 2A-2C at the same time. FIG. 2A shows a partial top view of the paper width detection device and paper tray according to Embodiment 1 of the present invention. FIG. 2B shows the paper width detection device and paper feeding in FIG. 2A A partial side view of the cassette, FIG. 2C shows a circuit block diagram of the paper width detecting device of FIG. 2A. In FIGS. 2A-2C , the paper width detecting device 30 is set on a paper tray 22, and the paper tray 22 is set on a paper feeder, such as an automatic document feeder (ADF). The paper tray 22 has at least one chute, such as chute 24a-24d. The paper width detection device 30 includes a conductive component 32 , a circuit board 34 , a control processing unit 36 and at least one paper guide, such as paper guides 23 a and 23 b. The paper guide sheets 23a and 23b can slide on the sliding grooves 24a and 24b and the sliding grooves 24c and 24d respectively. The paper guide pieces 23 a and 23 b can mo...

Embodiment 2

[0029] Please refer to Figures 3A to 3C at the same time, Figure 3A shows a partial top view of the paper width detection device and paper tray according to Embodiment 2 of the present invention, and Figure 3B shows the paper width detection device and paper feeding in Figure 3A A partial side view of the cassette, FIG. 3C shows a circuit block diagram of the paper width detecting device of FIG. 3A. The difference between the present embodiment and the first embodiment lies in the paper width detecting device 50 , as for the other same components, the reference numerals will continue to be used and will not be repeated.

[0030] The paper width detection device 50 includes a conductive component 52, a circuit board 54, a control processing unit 56 and at least one paper guide sheet, such as paper guide sheets 23a and 23b, and the paper guide sheets 23a and 23b are arranged on the Tray 22 on. As shown in FIG. 3B, the conductive component 52 is arranged under any one of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com