Method for measuring the width of laser lapping welding seam by using reflected echo of S0 mode lamb wave

A technique for overlapping welds and measuring methods, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of Lamb wave dispersion, complex signals, and unfavorable defect identification and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034]To detect lap welds formed by laser welding of two 2mm thick 304 stainless steel plates (such as figure 1 , laser lap welding seam model) as an example to illustrate the method of measuring the width of laser lap welding seam with S0 mode Lamb wave.

[0035] Step 1): draw the dispersion curve of 2mm thick 304 stainless steel plate;

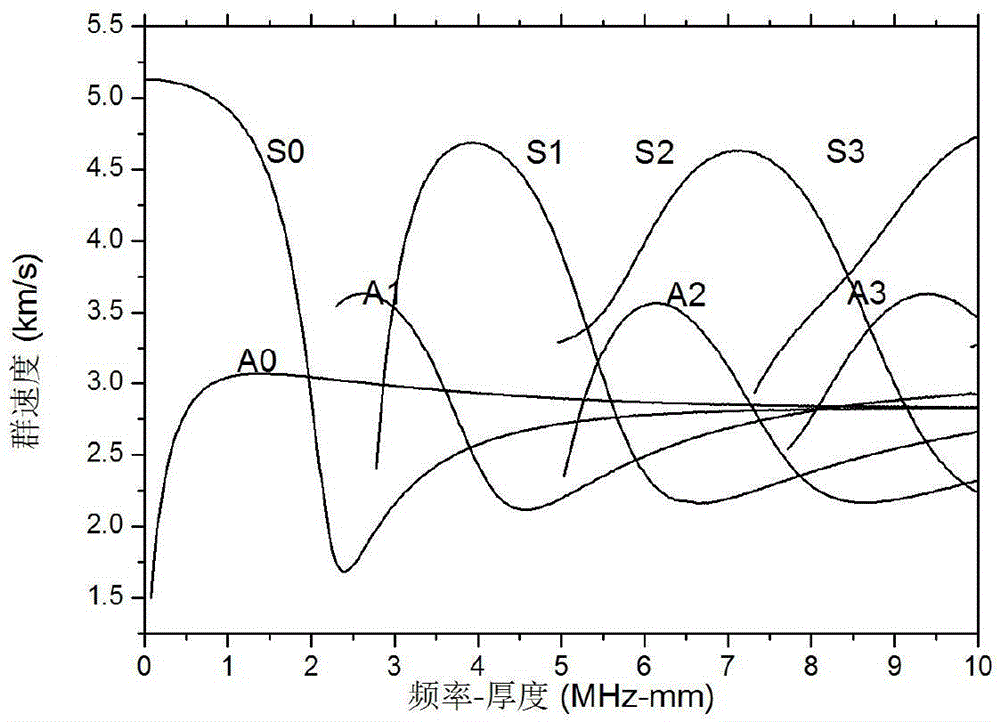

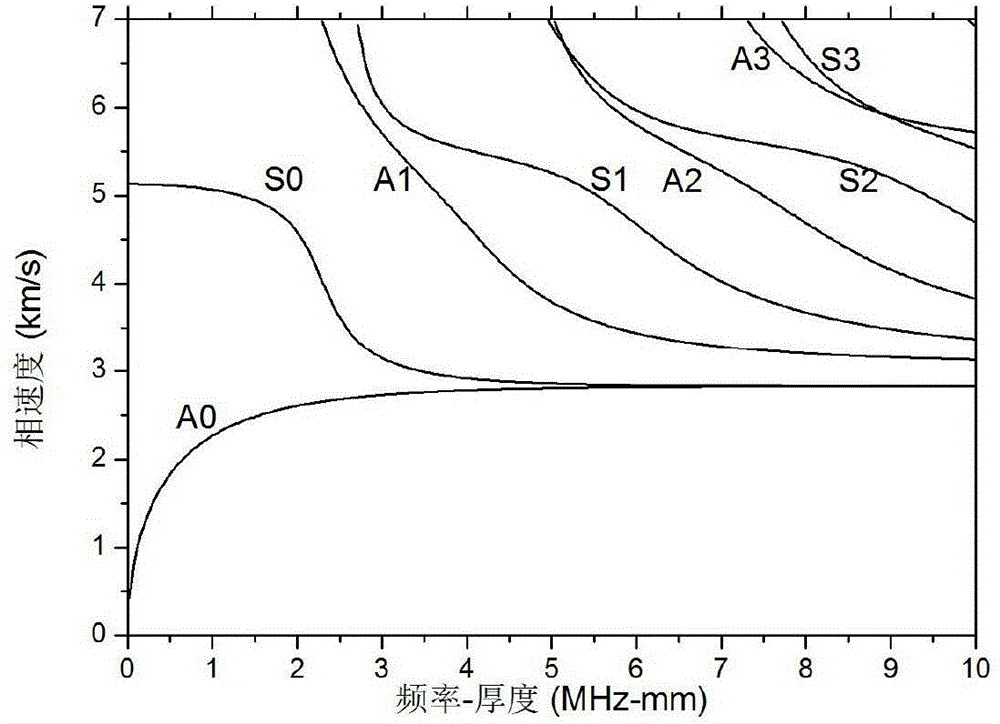

[0036] First, according to material parameters: density ρ=8000kg / m 3 , elastic modulus E = 193GPa, Poisson's ratio v = 0.29, to calculate the longitudinal wave velocity of the ultrasonic wave. The calculation formula is: Where λ=vE / [(1+v)(1-2v)], μ=E / 2(1+v) is the Lame coefficient of the material. The dispersion curve is obtained by numerical calculation based on the formula derived from viktolov theory, and the dispersion curve of the 2mm thick 304 stainless steel plate is obtained as follows figure 2 , 3 shown.

[0037] Step 2): Establish the detection frequency of Lamb wave;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com