Rolling drum washing machine

A drum-type washing machine and drum technology, applied in the field of washing machines, can solve the problems of inability to complete, insufficiently perform washing, rinsing, and inability to do laundry, and achieve the effect of eliminating anxiety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

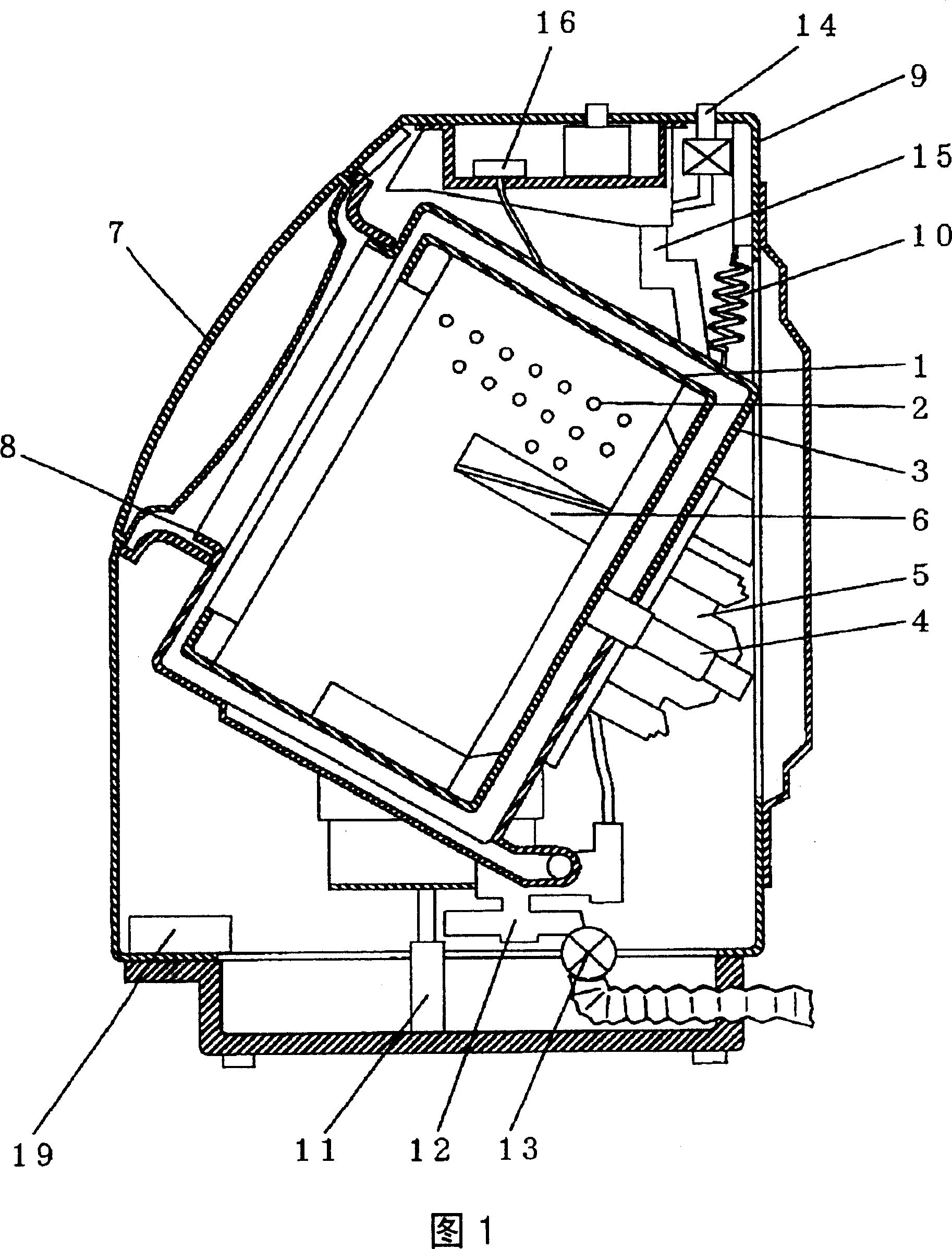

[0016] As shown in FIG. 1 , the rotary drum 1 is in the shape of a bottomed cylinder, and is provided with many water holes 2 on the entire outer circumference thereof, and is rotatably arranged in a water tub 3 . At the center of rotation of the rotating drum 1 is provided a rotating shaft (rotation center shaft) 4 substantially in an inclined direction, and the direction of the axis of the rotating drum 1 is set to be inclined downward from the front side to the back side. This rotating shaft 4 is connected with the motor 5 that is installed on the back side of the tub 3, and the rotary drum 1 is driven by the motor 5 to rotate in forward and reverse directions. A plurality of protruding plates 6 are provided on the inner wall surface of the rotary drum 1 .

[0017] An opening portion is provided on an upwardly inclined surface on the front side of the tub 3 , and the opening portion is covered by a cover 7 in a freely openable and closable manner. After the machine cover 7...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap