Separator for hexagon bare tyre ring of tyre ring

A separation device, technology in the shape of a hexagon in the direction of tires, applications, home appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

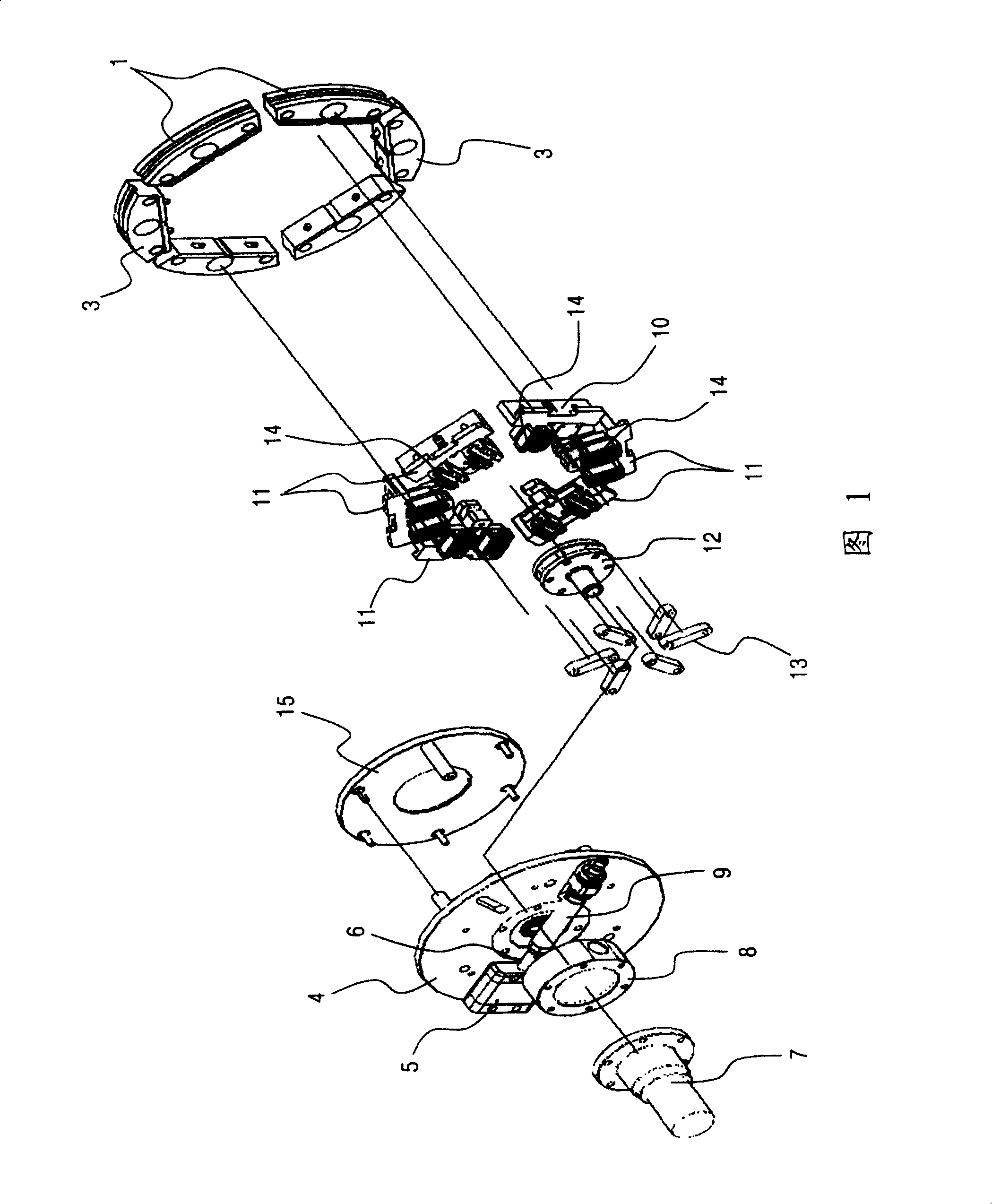

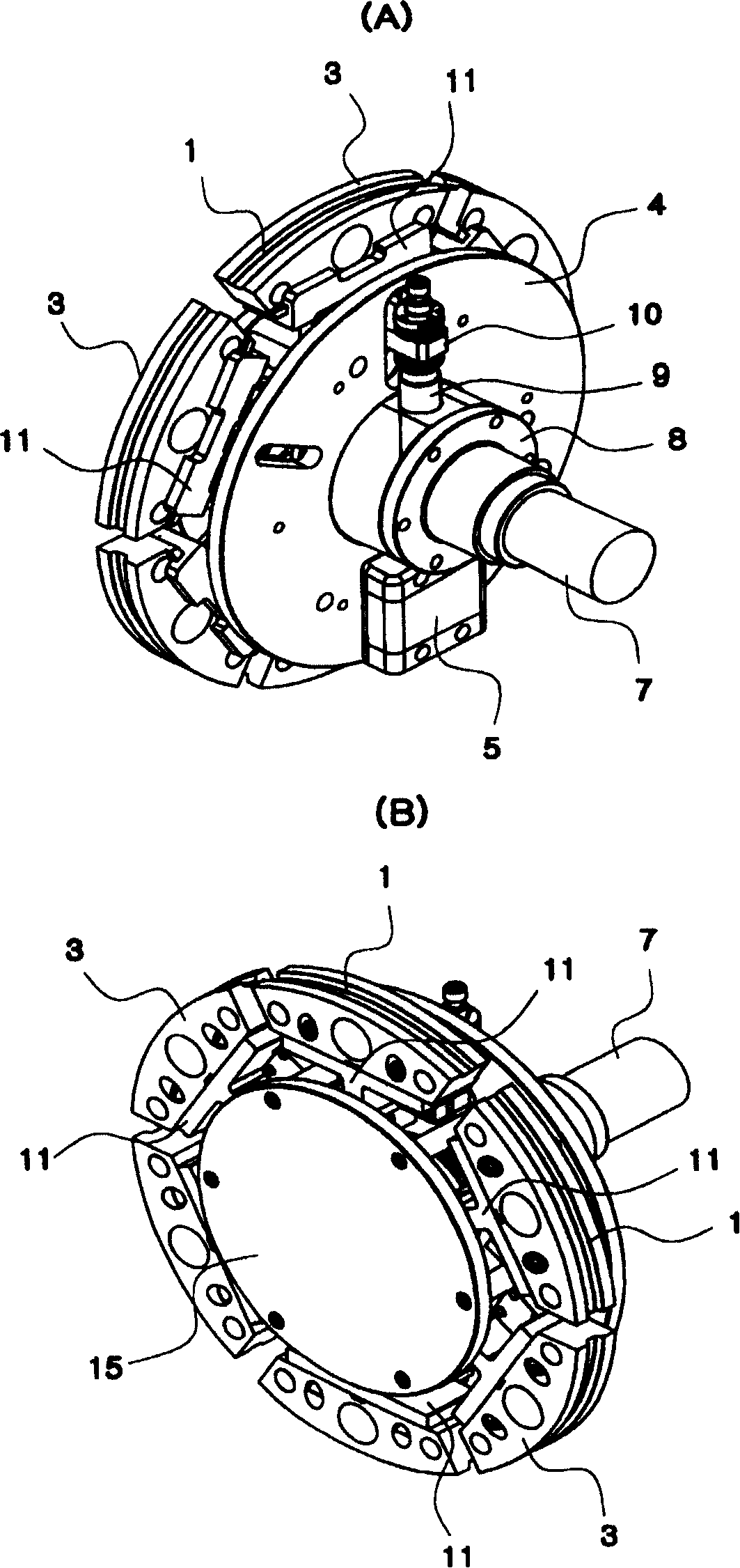

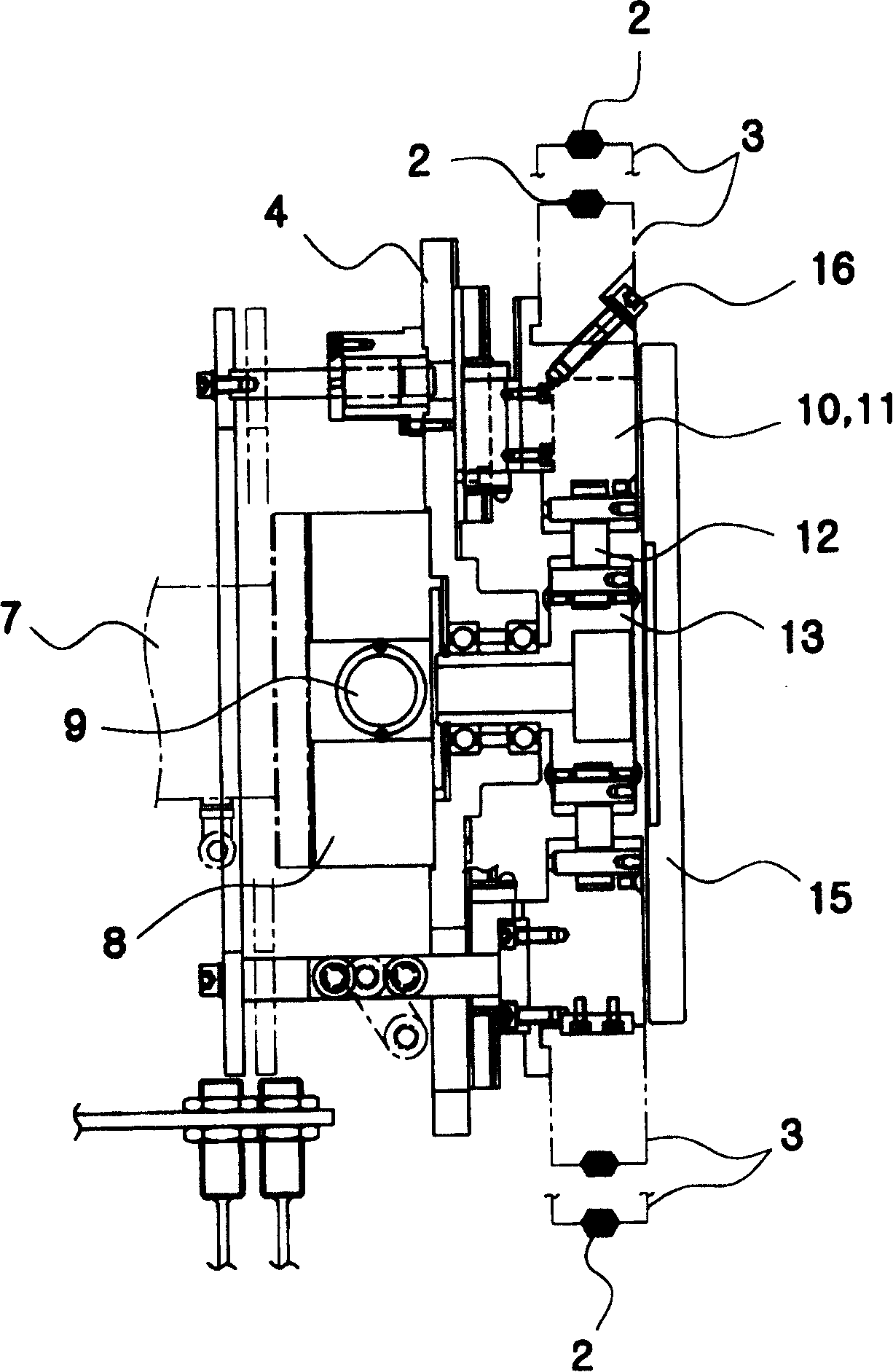

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The present invention relates to a manufacturing device that winds a plurality of steel wires on a circumferential groove 1 of a forming device to form a bare bead 2 with a hexagonal cross section. Among them, the circumferential division piece 3 formed with the above-mentioned circumferential groove 1 is attached to the supporting circular plate 4 . On the supporting circular plate 4, an air cylinder 5 is also fixedly installed. The rod 6 of the air cylinder 5 is connected to a radiation shaft 9 . Radiation shaft 9 penetrates slider 8 connected to rotation shaft 7 . A driving guide block 10 is connected to the radiation shaft 9 , and a follower guide block 11 driven by the above-mentioned driving guide block 10 and a rotating body 12 located at the center of the supporting circular plate 4 are connected through a rotating link 13 .

[0016] Here, linear bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com