Testing device of a flat-plate shaped body to be tested

A test device and a technology to be inspected are applied in the direction of measuring devices, measuring device casings, and components of electrical measuring instruments. Mobile and other issues, to achieve the effect of light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

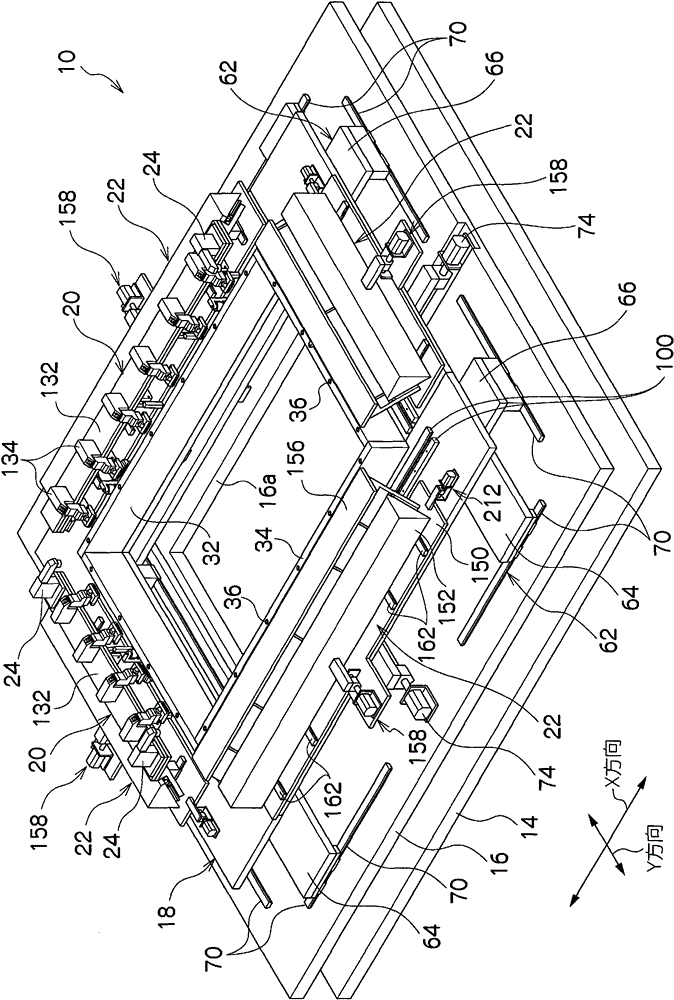

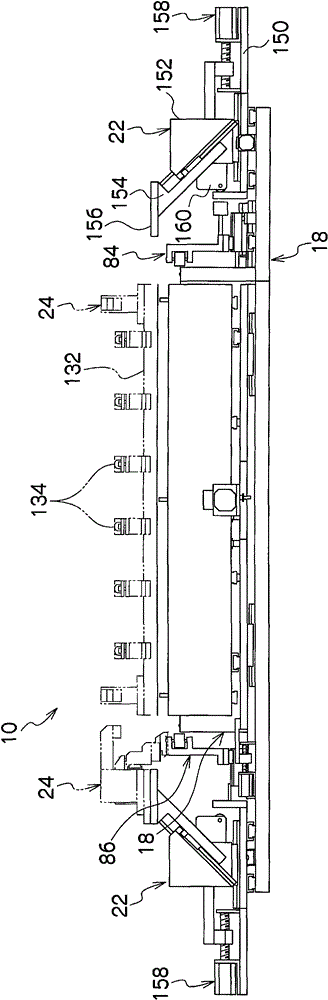

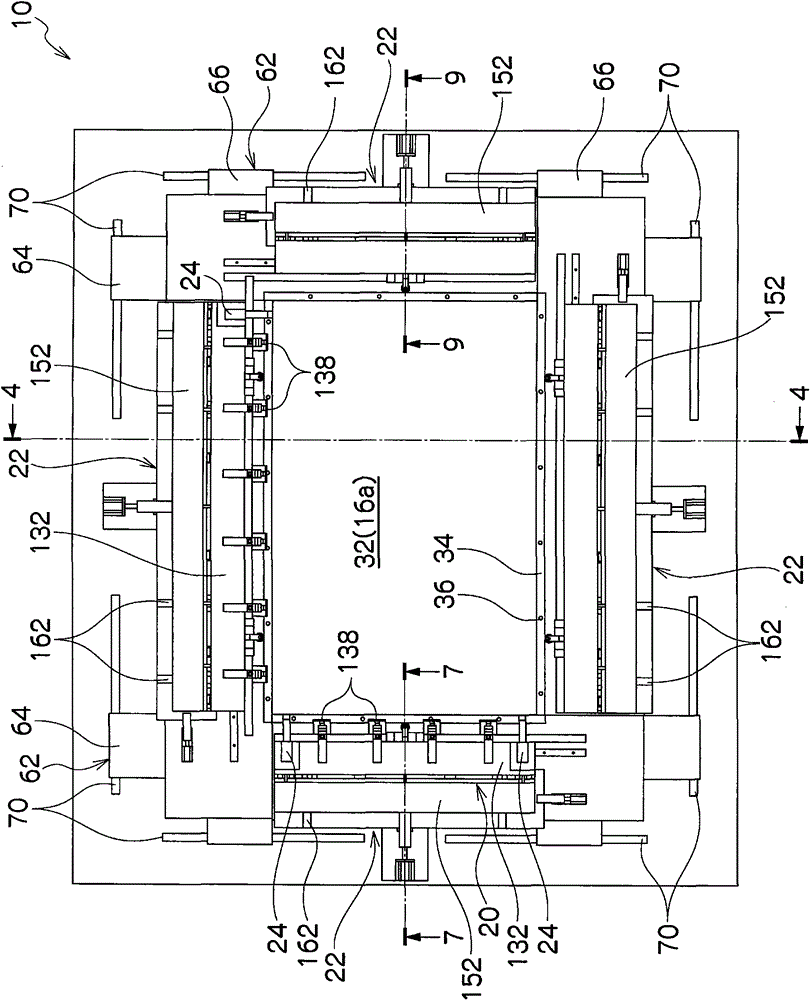

[0088] refer to Figure 1 ~ Figure 4 , the test device 10 uses a display panel as a flat panel to be inspected as a flat panel to be inspected as a liquid crystal display panel such as a liquid crystal display panel (see Figure 4 , 7, 9, etc.), and the object 12 to be inspected is connected to a predetermined circuit, thereby being used as a device for performing an electrical test such as a lighting inspection.

[0089] The object 12 to be inspected has a rectangular shape, and also has a plurality of electrodes on edges corresponding to several sides of the rectangle. Hereinafter, for easy understanding, a configuration in which the object 12 to be inspected has a long rectangular shape in the X direction will be described. In the illustrated example, the object 12 to be inspected has a plurality of electrodes at intervals in the longitudinal direction of two edges corresponding to adjacent sides of the rectangle, respectively, at intervals of the corresponding edges.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com