Method and technology of producing precipitated barium sulphate using white carbon black waste liquor

A technology for precipitating barium sulfate and white carbon black, applied in the direction of calcium/strontium/barium sulfate, alkali metal sulfide/polysulfide, etc., can solve problems such as waste liquid pollution, save water resources, reduce production costs, The effect of eliminating impurity contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

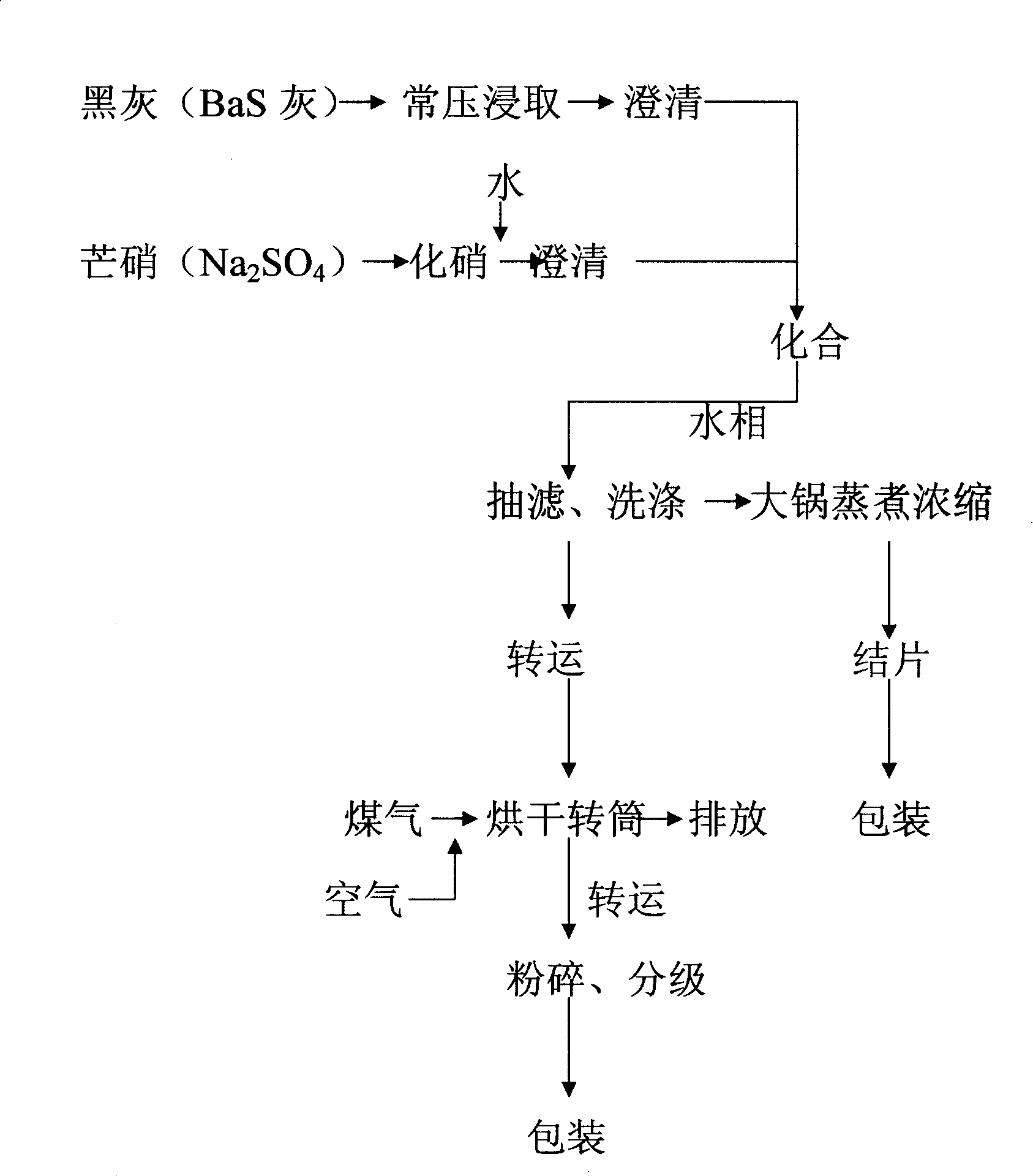

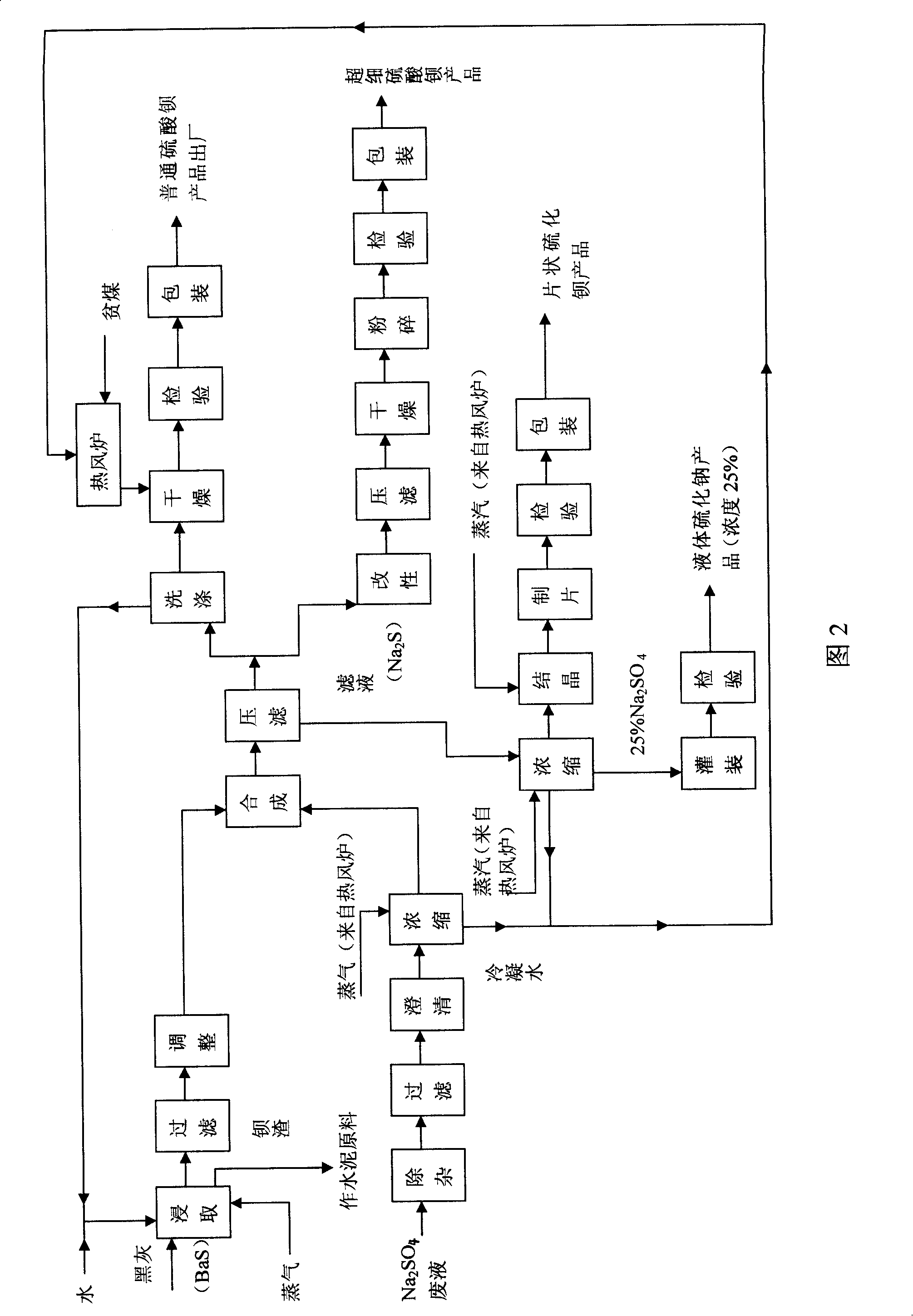

[0013] Using the white carbon black waste liquid in the production of hydrated precipitated silica, the white carbon black waste liquid is adjusted-removing impurities-filtered-concentrated so that the white carbon black waste liquid becomes only containing sodium sulfate (Na 2 SO 4 )The solution. Precipitated barium sulfate was prepared by white carbon black waste liquor-black ash method. Wherein said white carbon black waste liquid - black ash method is: the white carbon black waste liquid is adjusted through adjustment--removal of impurities--filter--concentration, and then mixed with black ash leaching liquid to carry out metathesis reaction and solidification After liquid separation, precipitated barium sulfate and precipitated sodium sulfide were obtained. The production reaction formula is BaS+Na 2 SO 4 (concentration about 20%)-BaSO 4 ↓+Na 2 S. The specific process is:

[0014] 1. Put the white carbon black waste liquid in the adjustment tank and use OH - (0.1...

Embodiment 2

[0022] Using the white carbon black waste liquid in the production of hydrated precipitated silica, the white carbon black waste liquid is adjusted-removing impurities-filtered-concentrated so that the white carbon black waste liquid becomes only containing sodium sulfate (Na 2 SO 4 )The solution. Precipitated barium sulfate was prepared by white carbon black waste liquor-black ash method. Wherein said white carbon black waste liquid - black ash method is: the white carbon black waste liquid is adjusted through adjustment--removal of impurities--filter--concentration, and then mixed with black ash leaching liquid to carry out metathesis reaction and solidification After liquid separation, precipitated barium sulfate and precipitated sodium sulfide were obtained. The production reaction formula is BaS+Na 2 SO 4 (concentration about 20%)-BaSO 4 ↓+Na 2 S. The specific process is:

[0023] 1. Prepare the black ash immersion solution from the barite according to the convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com