Organic waste-water treating apparatus utilizing coal slag

A technology for organic wastewater treatment and cinder, which is used in energy wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of difficulty in achieving wastewater treatment efficiency, difficulty in forming a circulating flow on the surface of cinder, and small wastewater holding capacity. , to achieve the effect of simple purification treatment operation and process, uniform wastewater treatment efficiency, and good wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings, and the embodiments of the present invention are described within the scope that those skilled in the art can implement the present invention.

[0023] The embodiments of the present invention can be changed and implemented in various forms, and therefore, the scope of claims of the present invention is not limited by the following embodiments.

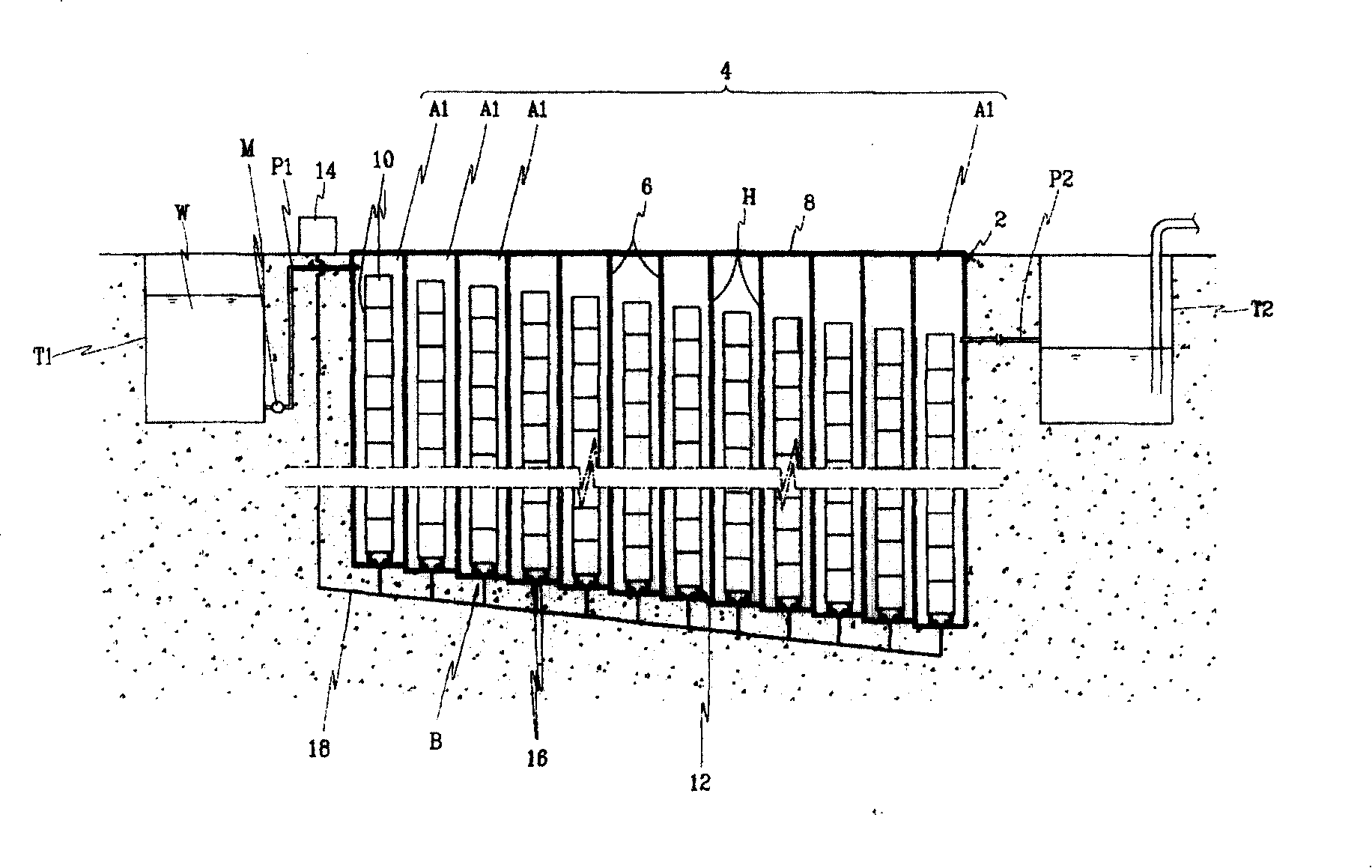

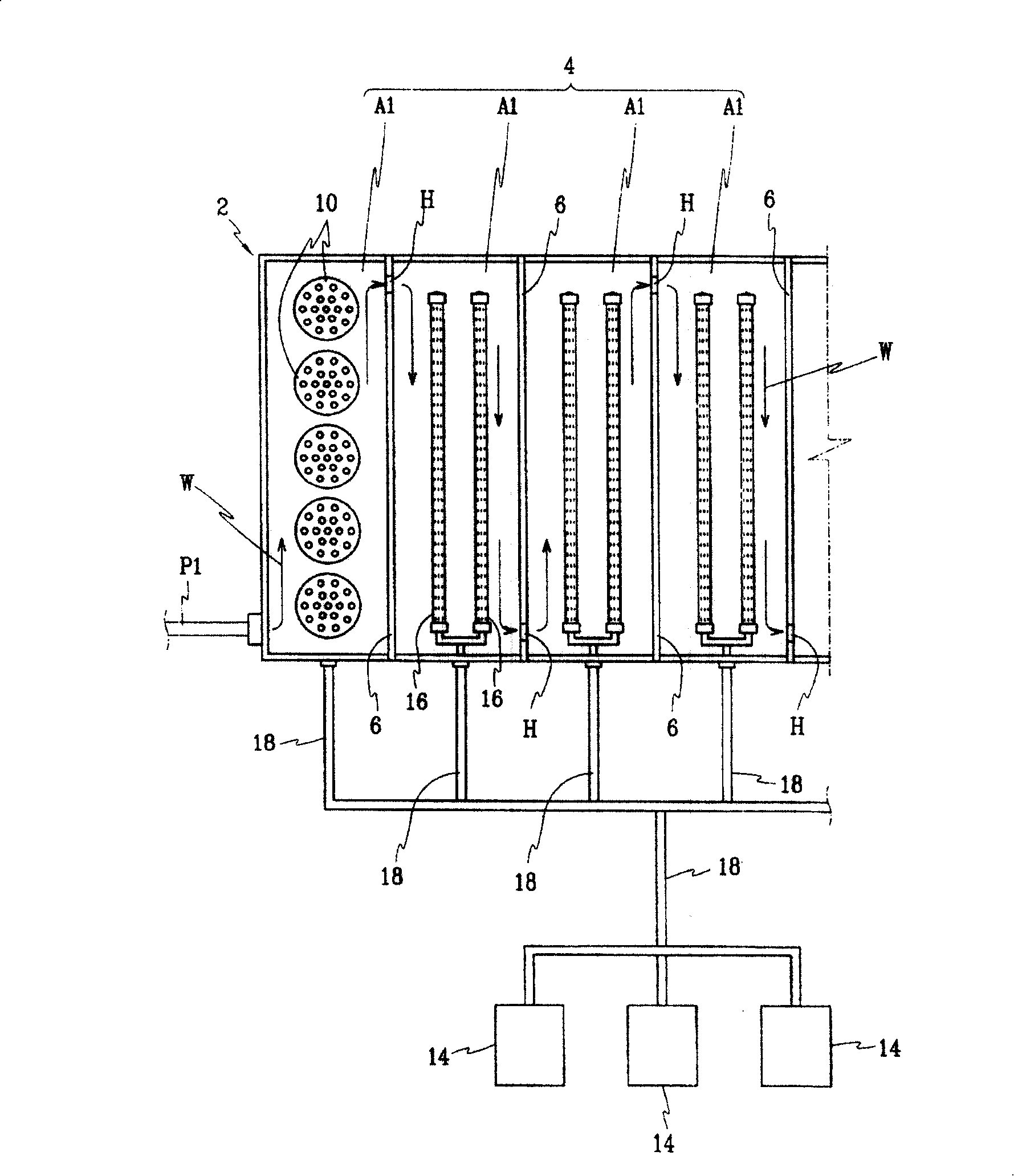

[0024] figure 1 It is a schematic cross-sectional view of the organic waste water treatment device using coal slag in the present invention. The number 2 in the figure represents the treatment tank body 2 for treating the waste water W. As shown in the figure, the treatment tank body 2 can be buried underground at a certain depth.

[0025] As shown in the figure, the treatment tank body 2 can be a box-like structure with a rectangular space 4 with an open upper end, which can be made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com