Apparatus for manufacturing flat display

A flat-panel display and manufacturing equipment technology, applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve problems such as unused load lock chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

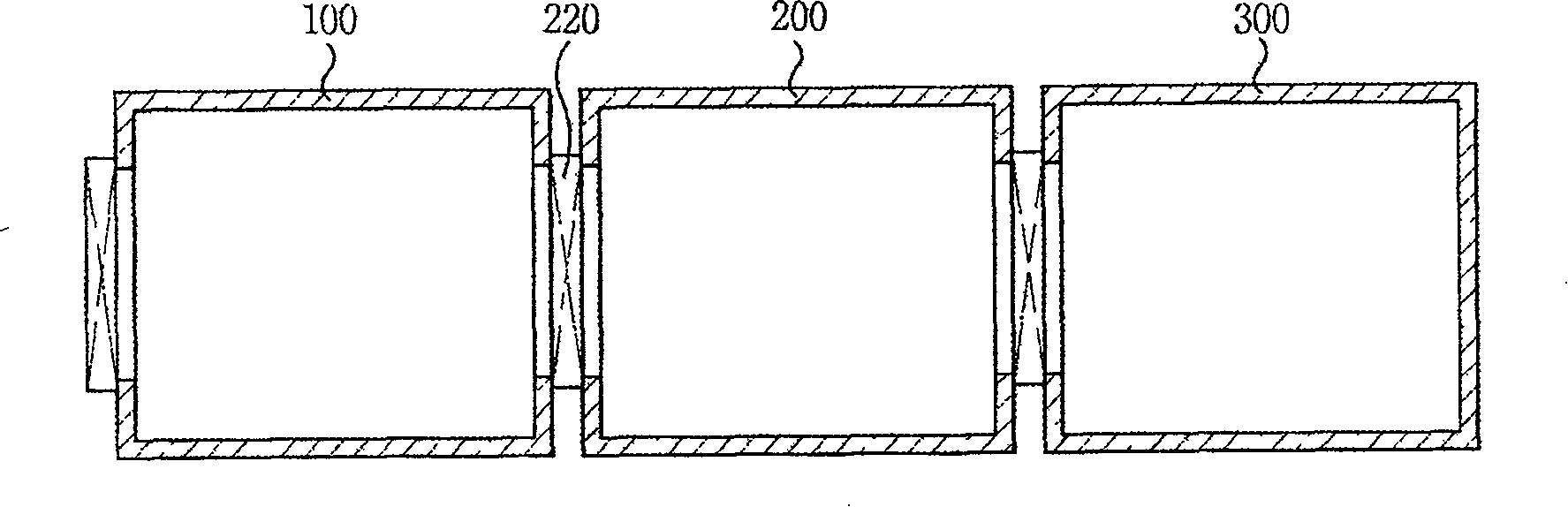

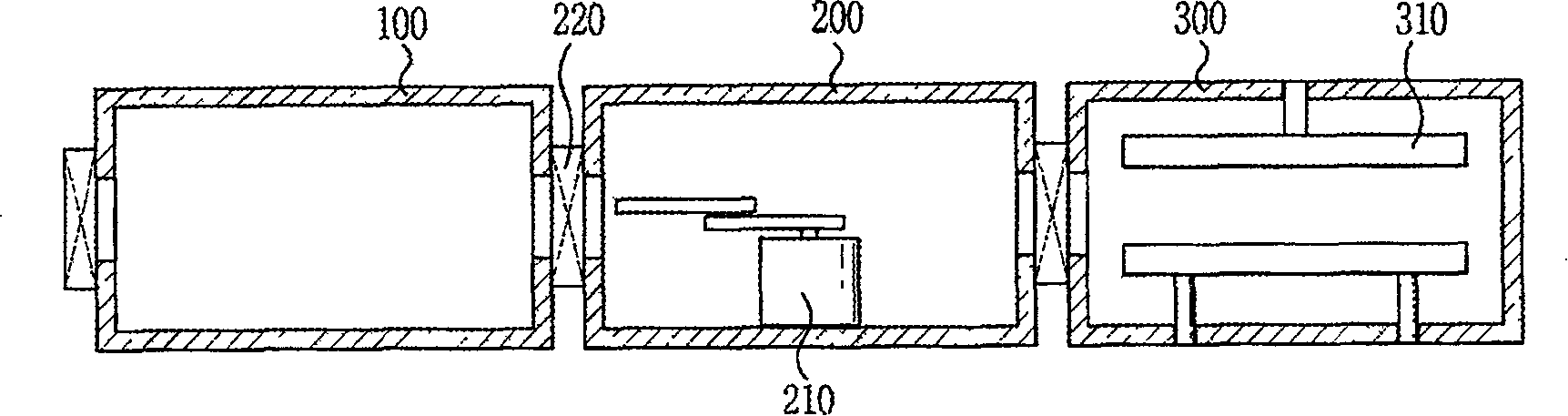

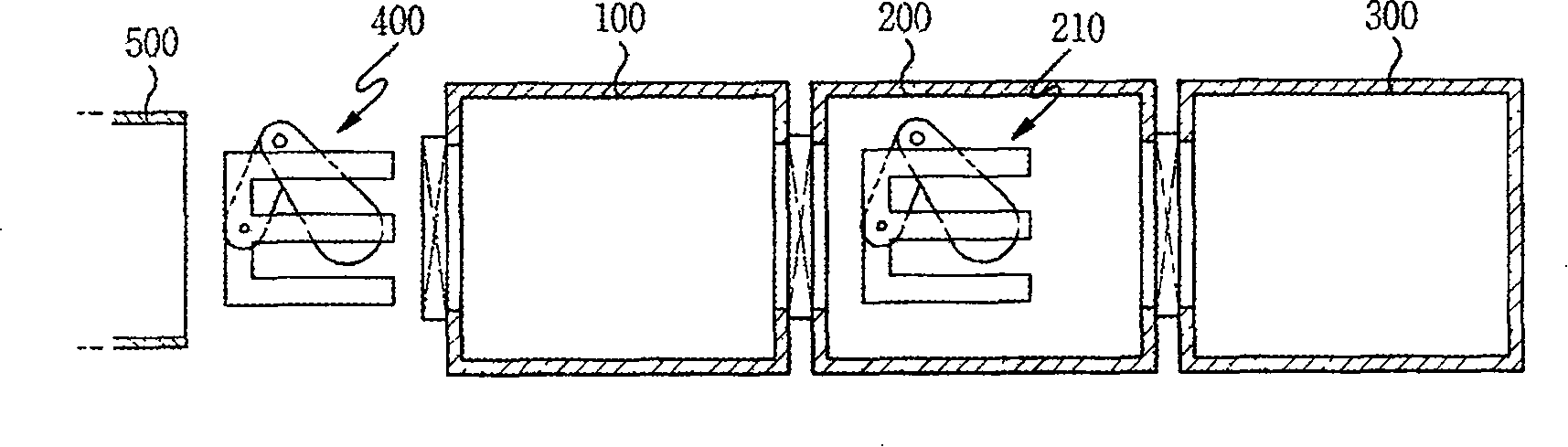

[0040]refer to Figure 4 Or 5, illustrates the FPD manufacturing equipment according to the first embodiment of the present invention. Such as Figure 4 or as shown in 5, the FPD manufacturing equipment includes such as Figures 1 to 3 The load lock chamber 100 and the feed chamber 200 are shown in the conventional case. The FPD fabrication facility also includes at least one process chamber 300 operatively connected to the feed chamber 200 , preferably at least two process chambers 300 . exist Figure 4 In the example of , two processing chambers 300 are provided. exist Figure 5 In the example of , three processing chambers 300 are provided. The load lock chamber 100 includes a plurality of gates arranged in pairs, such as Figure 6 shown in . In the example shown, a gate pair comprising two gates 110 and 120 is included in the load lock chamber 100 .

[0041] The substrate inlet 130 is formed at one side wall of the load lock chamber 100 opposite to the feed chambe...

no. 2 example

[0056] refer to Figure 10 Or 11, illustrates the FPD manufacturing equipment according to the second embodiment of the present invention. Such as Figure 10 As shown in or 11 , the FPD manufacturing facility includes a load lock chamber 100 and a feed chamber 200 . The FPD manufacturing apparatus also includes at least one process chamber 300 , preferably at least two process chambers 300 , which are operatively connected to the feed chamber 200 . exist Figure 10 In the example of , two processing chambers 300 are provided. exist Figure 11 In the example of , three processing chambers 300 are provided.

[0057] The substrate supporting unit 160 is disposed at one side of the load lock chamber 100 such that the substrate supporting unit 160 extends into or retracts from the load lock chamber 100 through one side wall of the load lock chamber 100 opposite to the feed chamber 200 . Corresponding to this extension and retraction, the substrate supporting unit 160 loads an...

no. 3 example

[0071] refer to Figure 14 , illustrates an FPD manufacturing apparatus according to a second embodiment of the present invention. Such as Figure 14 As shown in , the FPD manufacturing apparatus includes a load lock chamber 100 , a feed chamber 200 and a process chamber 300 . The substrate support units 160 are respectively provided at the sides of the load lock chamber 100 adjacent to the side walls of the load lock chamber 100 connected to the feed chamber 200 so that each substrate support unit 160 is connected to the load lock chamber 200 by connecting to the feed chamber 200. The side walls of the chamber 100 extend into or retract from the load lock chamber 100 adjacent to the side walls of the load lock chamber 100 . The FPD manufacturing equipment also includes a substrate feeding device 600 for loading a substrate S on each substrate support unit 160 ( Figure 17 ) and unload the substrate S from the substrate support unit 160.

[0072] Each substrate supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com