A cleaning unit of dish washer

A technology for cleaning devices and dishwashers, which is applied to parts of washing machines/rinsing and washing machines for tableware, and can solve the problems of insufficient distribution range, small rotating torque of spray arms, and poor cleaning effect of tableware, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

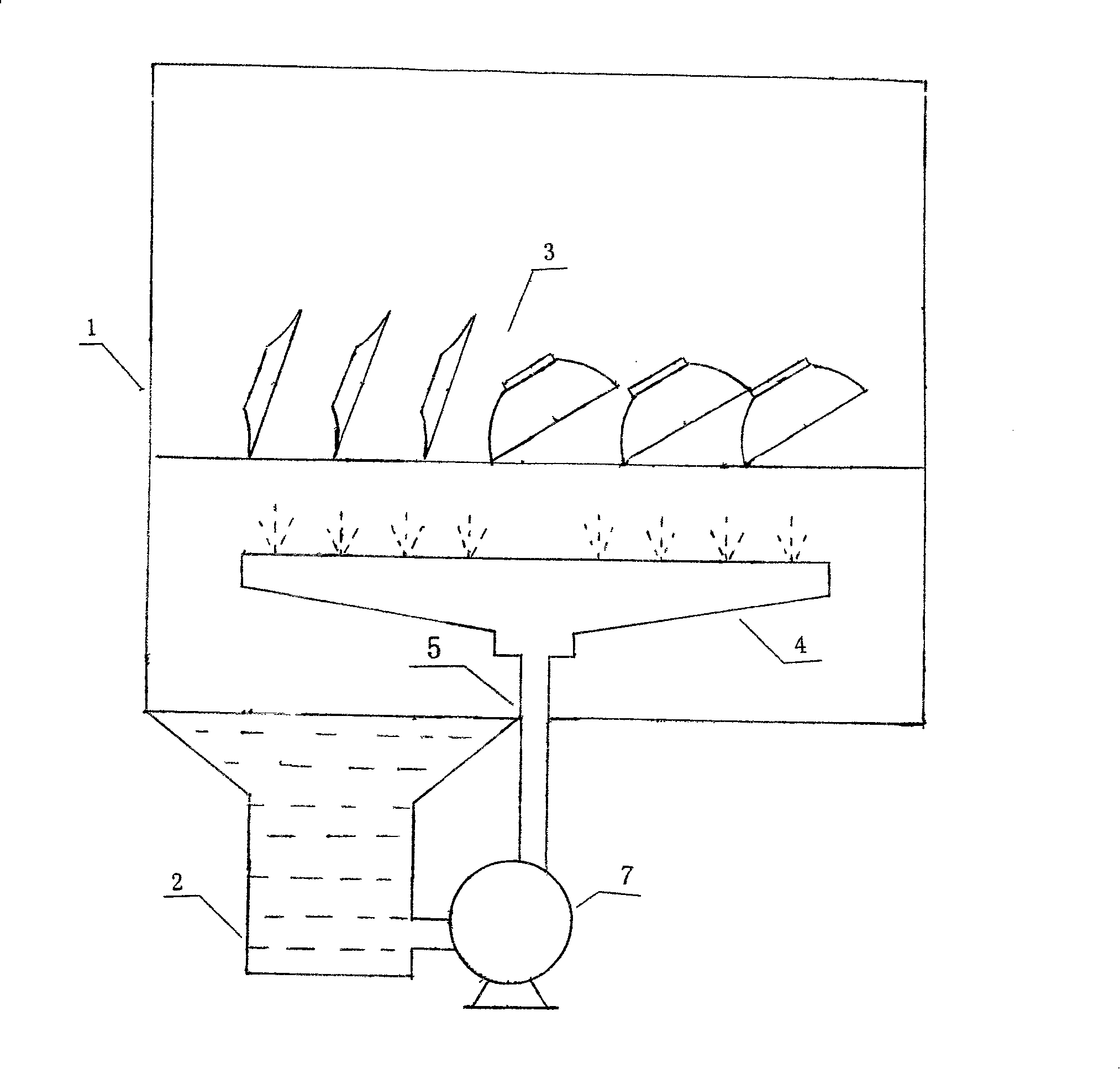

[0010] Such as figure 1 As shown, it is a structural schematic diagram of an existing dishwasher cleaning device. The water pressurized by the water pump 7 is directly sprayed from the nozzle on the spray arm 4 through the hollow rotating shaft 5 to clean the tableware 3 .

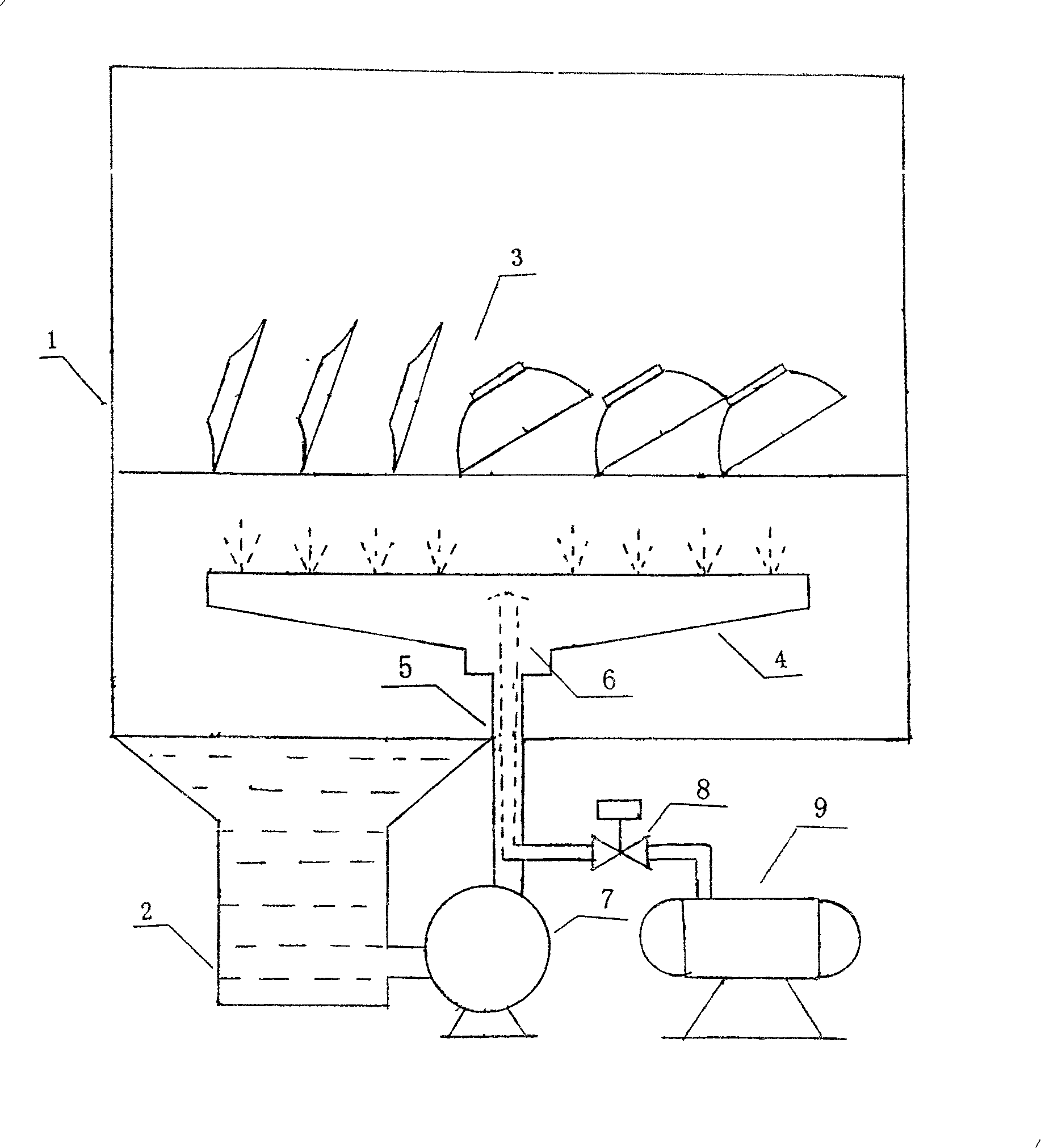

[0011] Such as figure 2 Shown is a structural schematic diagram of the dishwasher cleaning device of the present invention, including a dishwasher inner box 1, a pool 2, a spray arm 4, a hollow shaft 5, a water pump 7, a solenoid valve 8, a Air compressor9. The water inlet end of the water pump 7 is connected with the pool 2, and the water outlet end of the water pump 7 is connected with the hollow rotating shaft 5, and the rotatable spray arm 4 is housed on the hollow rotating shaft 5. There is a compressed air intake pipe 6 extending into the hollow rotating shaft 5 inside and extending to the top of the hollow rotating shaft 5 at the lower section of the hollow rotating shaft 5 . The reason why the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com