Manufacturing method and structure of organic luminous display panel

A technology for luminescent display and manufacturing method, which is applied in the direction of electroluminescent light source, semiconductor/solid-state device manufacturing, light source, etc. It can solve the problems of bright lines and high brightness of finished panel products, and achieve the effect of improving the problem of bright lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

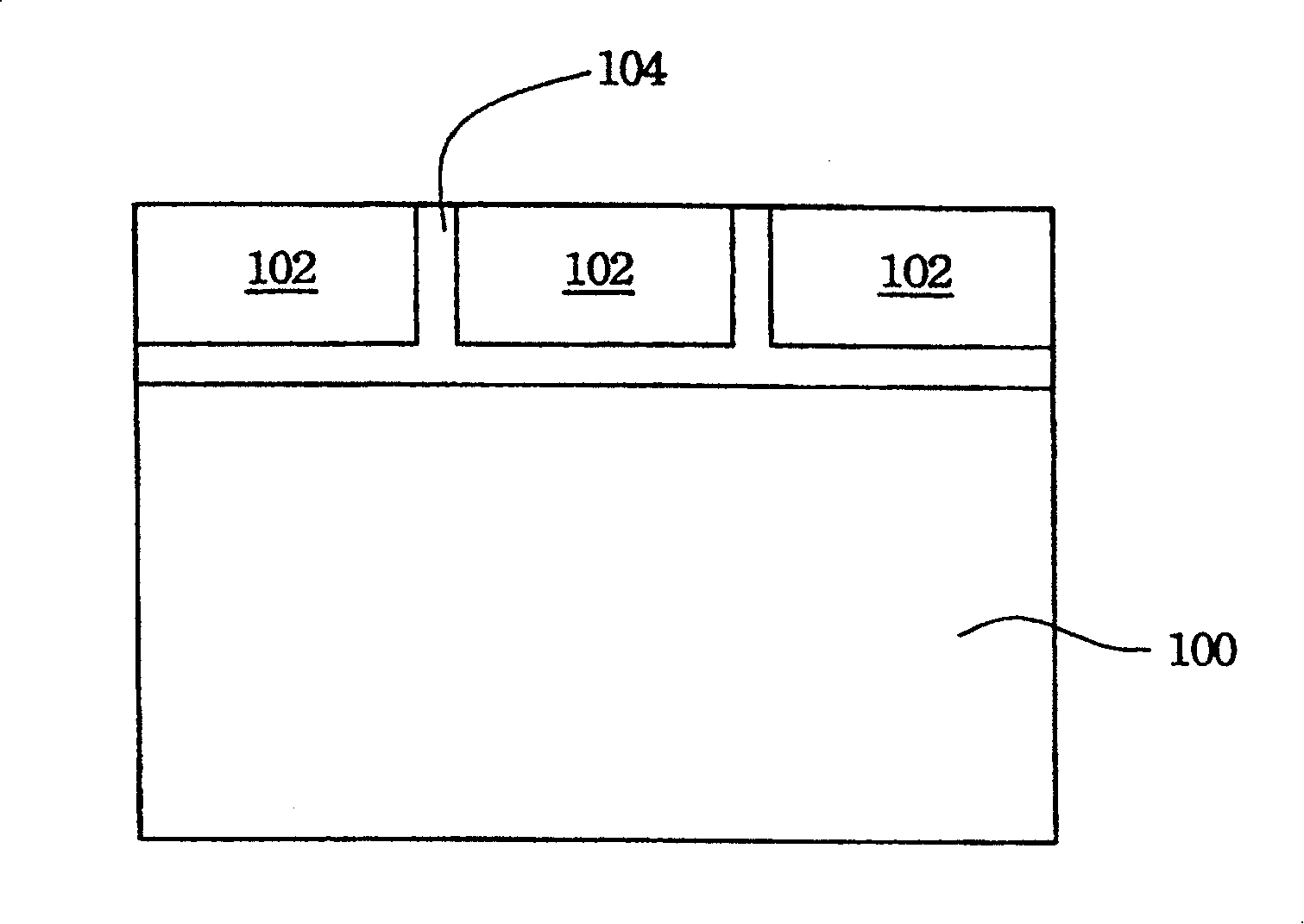

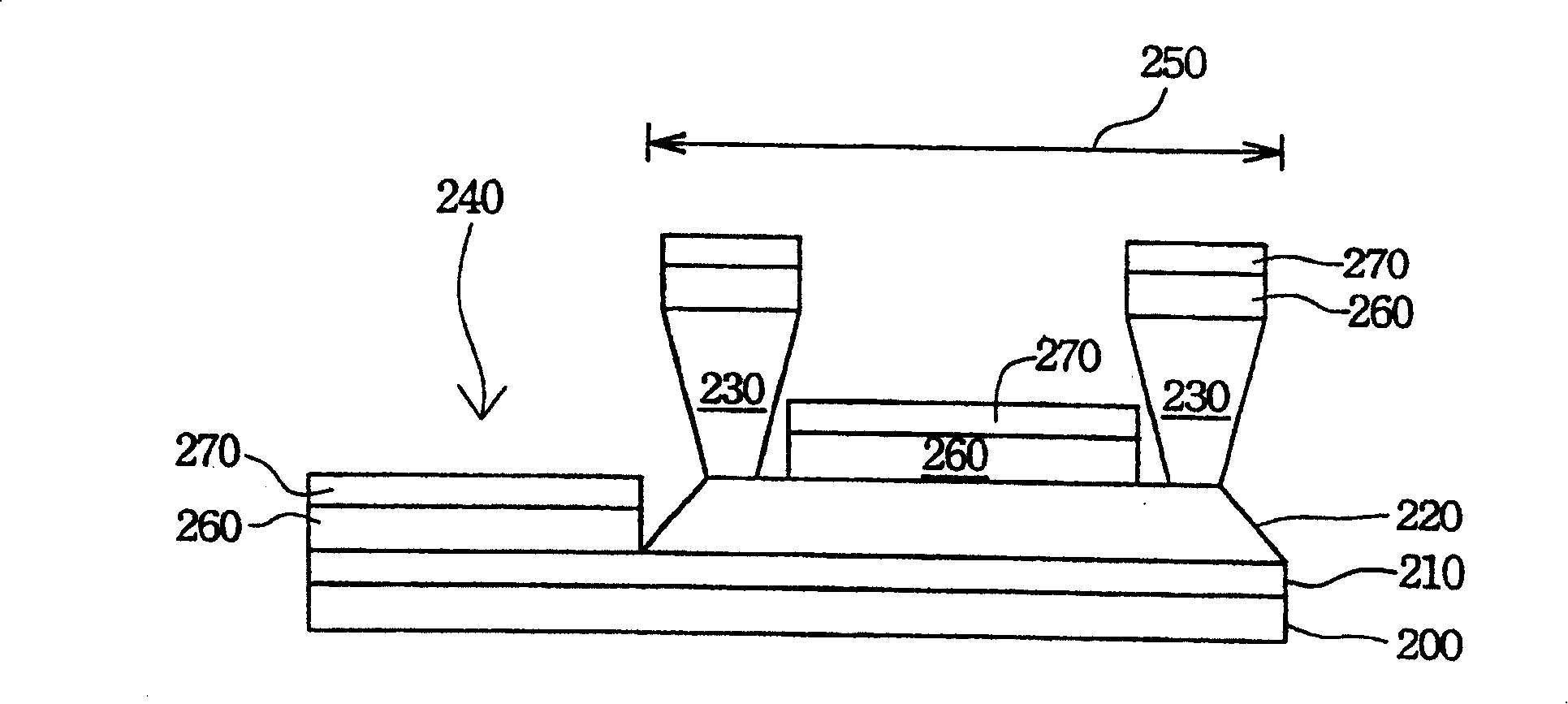

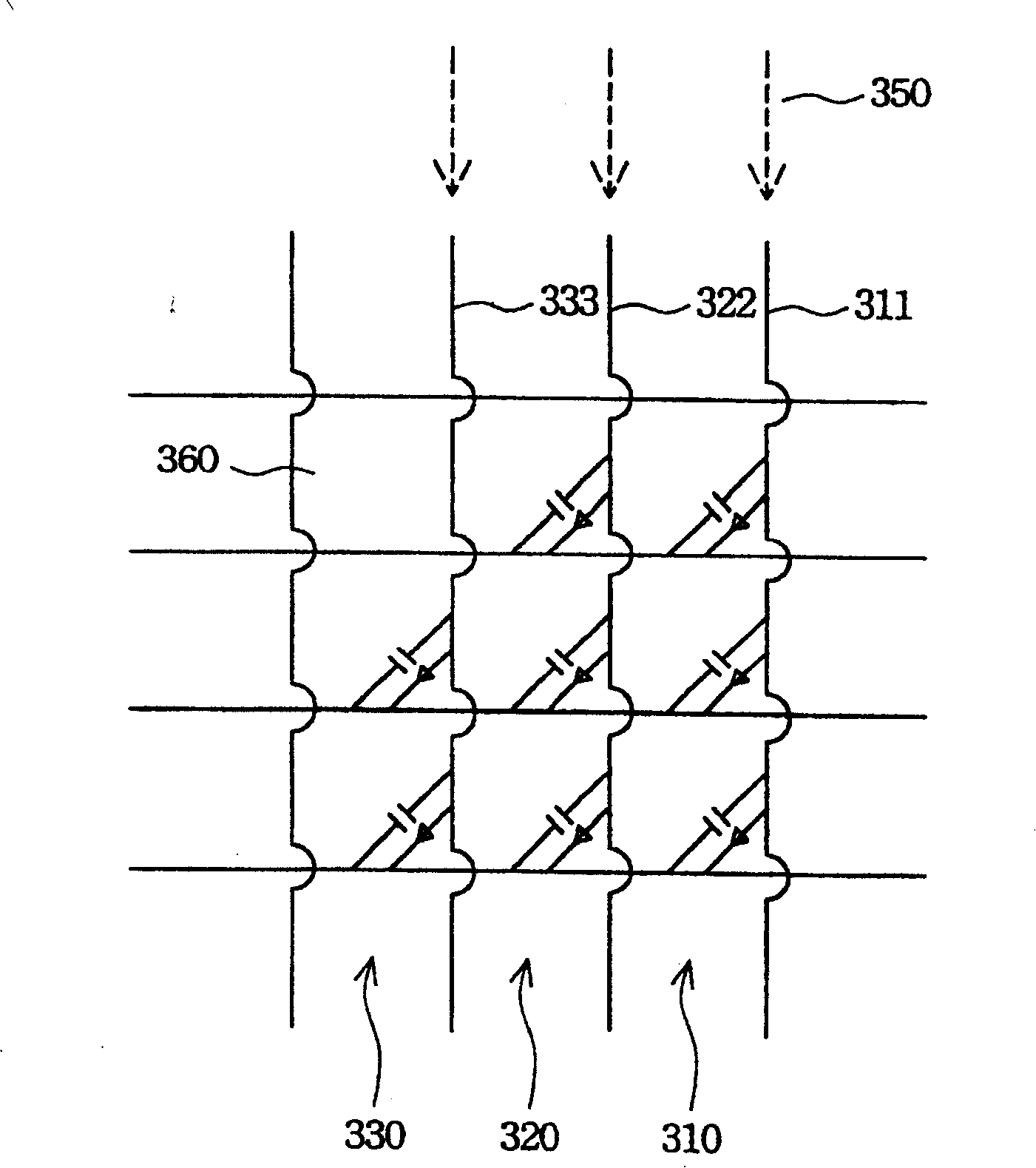

[0040] The invention is a manufacturing method and structure of an organic light-emitting display panel that can improve the bright line problem of the panel caused by the arrangement of non-luminous pixel areas around a specific image on the panel. By reducing the area occupied by the base layer, the area covered by the transparent electrode is reduced, so that part of the cathode conductive material on the non-luminous pixel area will not be completely isolated, but can provide part of the capacitance value when the current passes.

[0041] In this way, the originally low capacitance value of the lines passing through the non-luminous pixel area around the specific image is increased, so that the difference in the capacitance values of the lines on the panel is reduced. As a result, the brightness distribution of the panel is more uniform, and the problem of bright lines is improved.

[0042] The method of the present invention will be described in detail below with a pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com