Method for making fluid dynamic simulation process flow

A technology of process flow and dynamic simulation, applied in educational appliances, instruments, identification devices, etc., can solve the problems of idle LED display screen, unable to fully display the process links, difficult to use units, etc., which is conducive to long-term continuous operation and display. Full-featured, easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

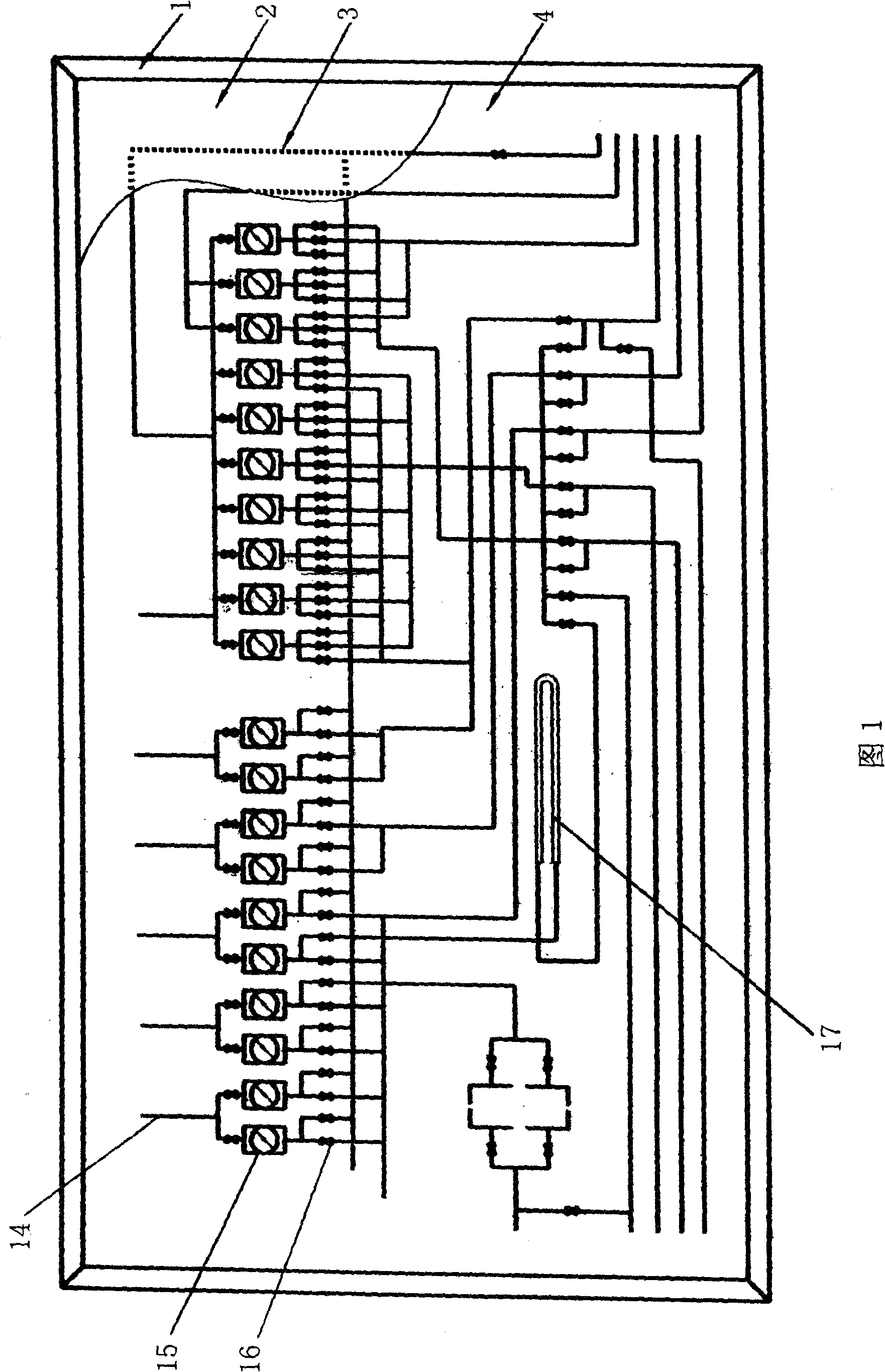

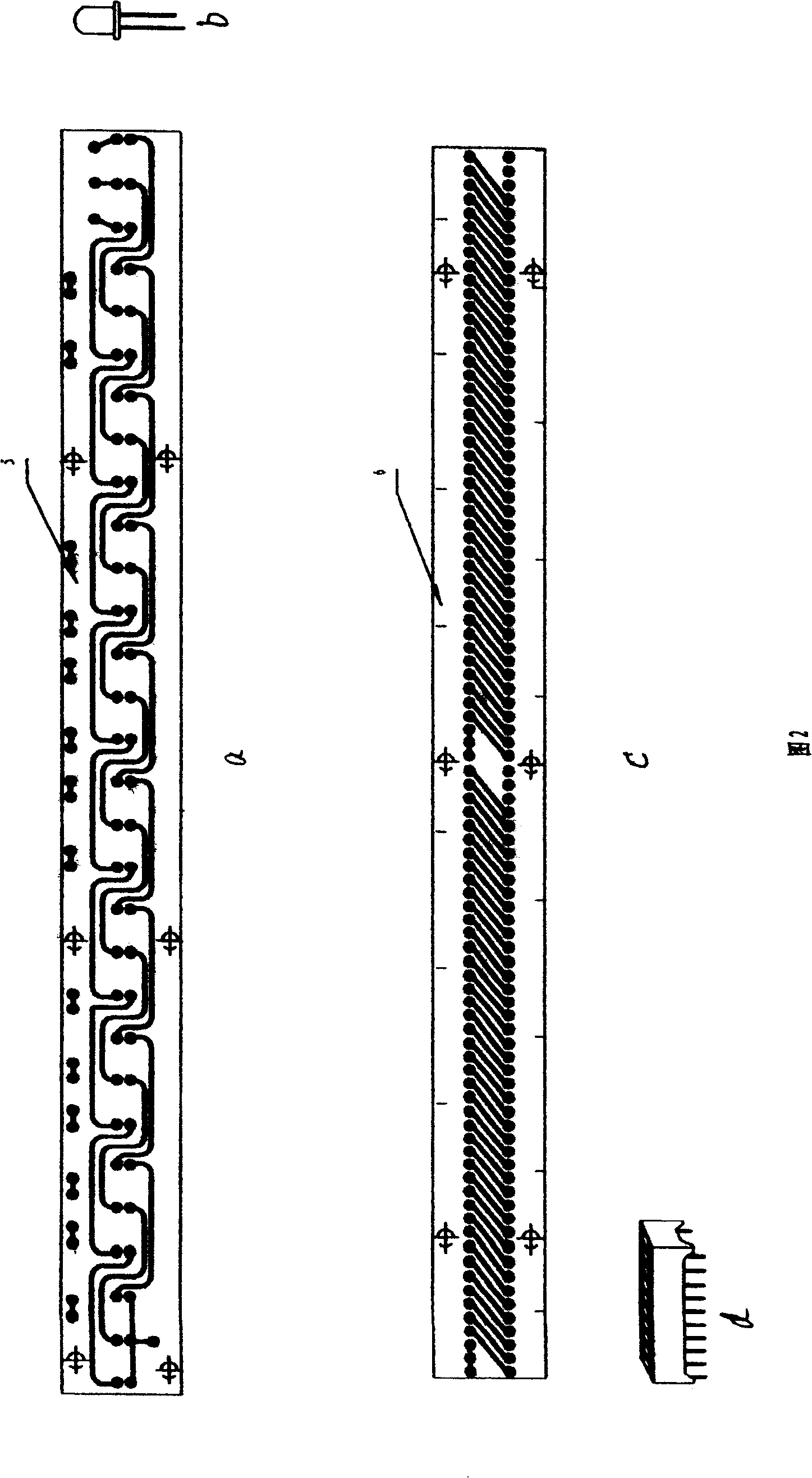

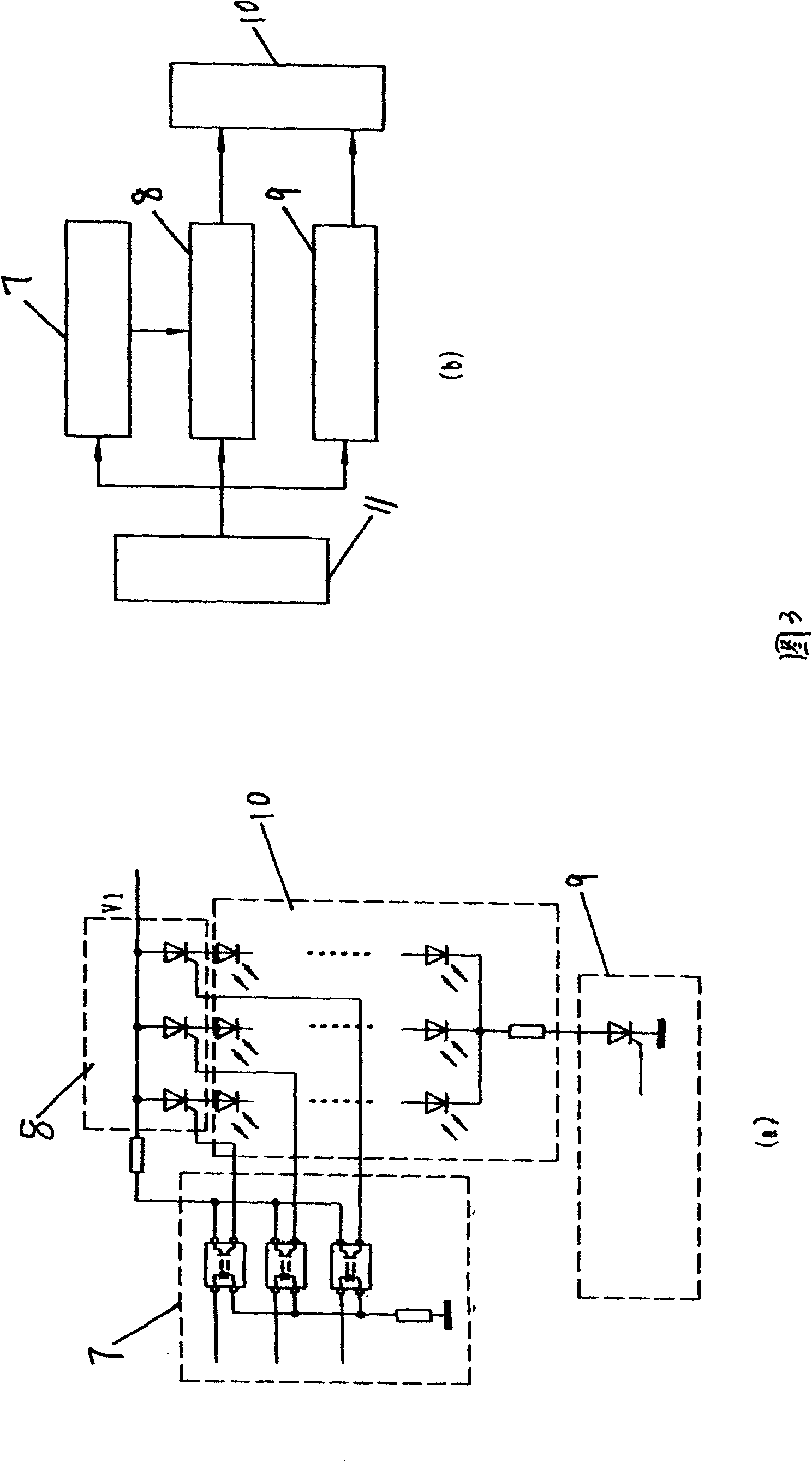

[0029] 1. The luminous bar assembly 3 adopts light-emitting diodes and semi-integrated LED luminous columns, which are respectively welded to the printed circuit boards 5 and 6 (see Figure 2) to display the process pipeline 14, flow meter 15, valve 16 and standard The working state of volume tube 17. The graphics of the flowmeter 15 and the standard volume tube 17 adopt light-emitting diode (see Figure 2b) components, first drill holes along the graphics on the substrate, and the hole distance is equal to the distance between the light-emitting tubes. 14. Use the luminous column (see Figure 2d) assembly, first groove on the substrate along the process, the groove width is equal to the width of the luminous column, and the end surface of the luminous column is flush with the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com