Upspring type flash lamp mechanism

A flash and camera technology, applied in optics, cameras, camera bodies, etc., can solve the problems of flash failure, complex structure, stuck, etc., and achieve the effect of avoiding action failure, compact overall structure, and tight coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

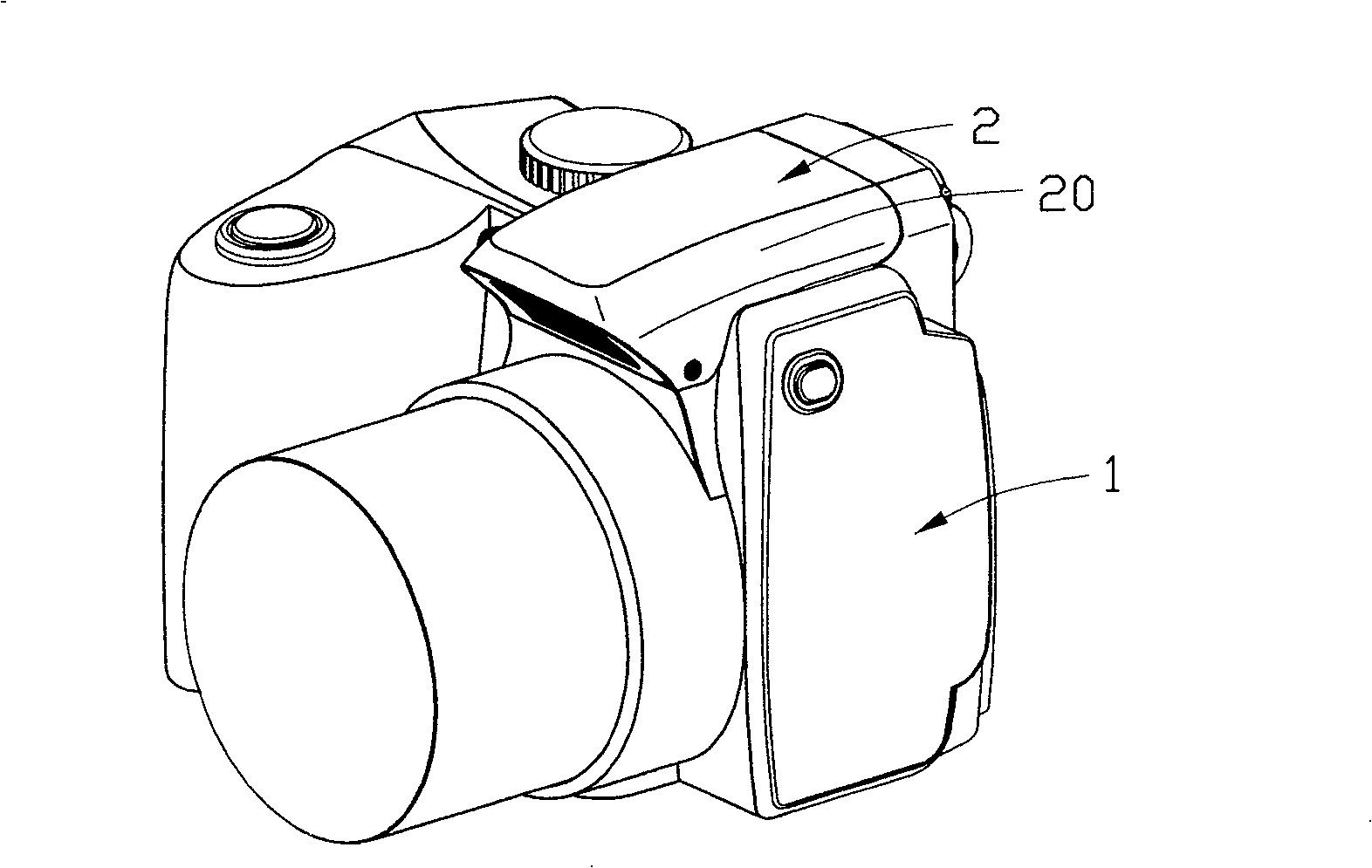

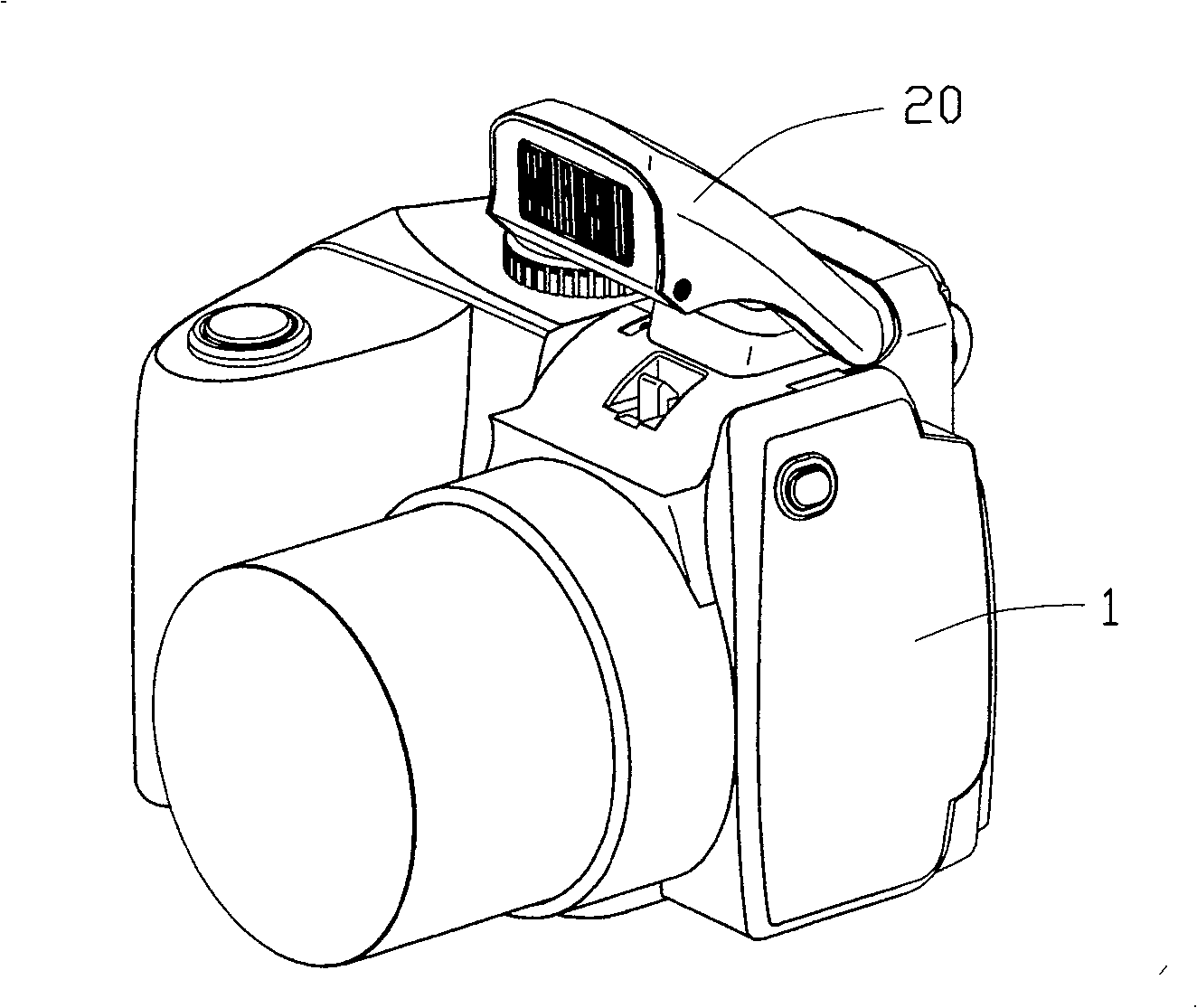

[0019] The pop-up flash mechanism 2 of the present invention can be applied to a digital camera, and it is installed on the camera body 1. When the camera is not working, please refer to Figure 1A As shown, the flashlight body 20 is in a horizontally closed state, and its light-emitting part faces downward, so as to realize concealment in appearance. When the camera is working and an auxiliary light source is required, please refer to Figure 1B As shown, the flashlight body 20 is in a pop-up state, and its light-emitting part faces forward.

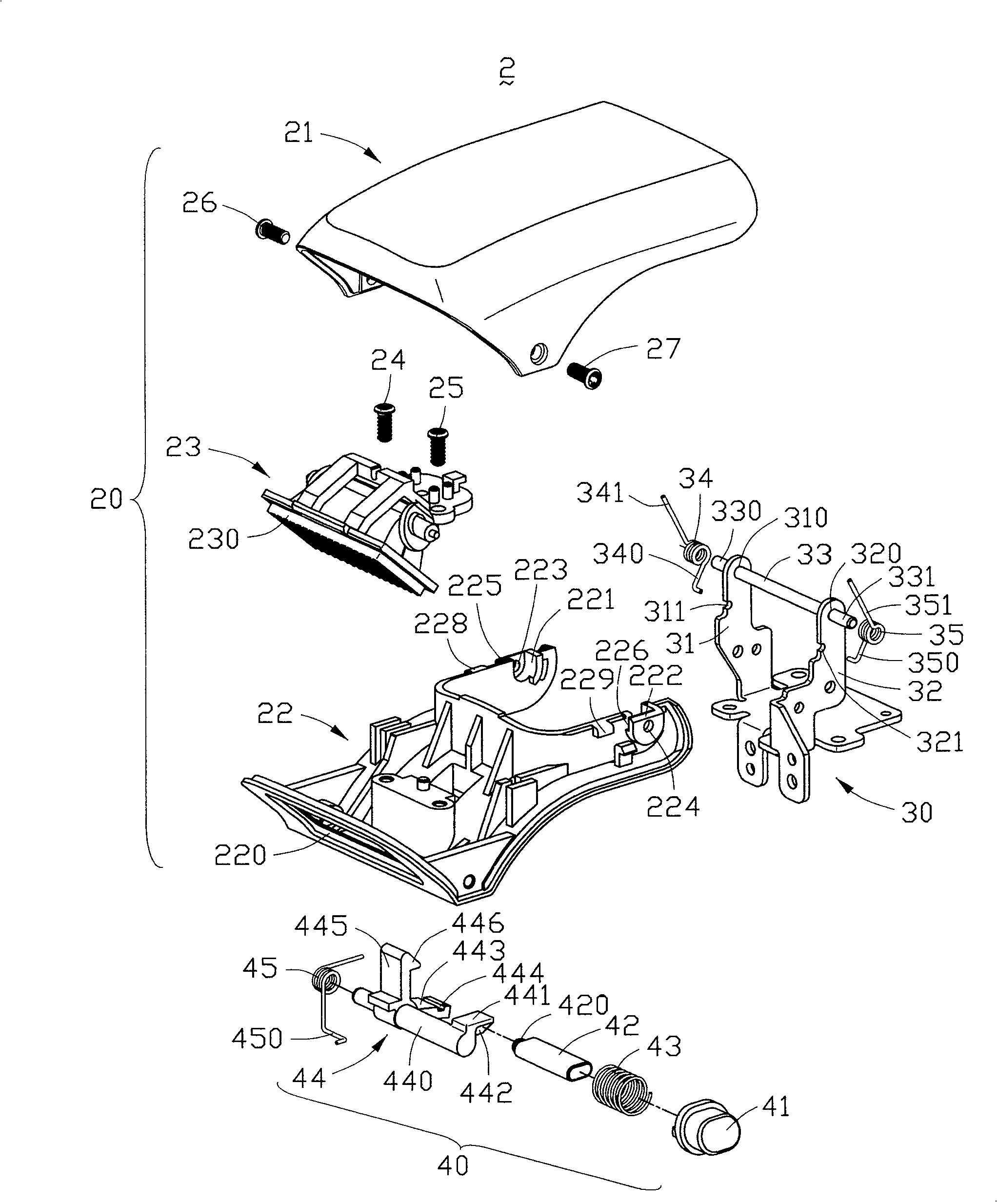

[0020] Please refer to figure 2 As shown, it is a preferred embodiment of the pop-up flashlight mechanism 2. The flashlight mechanism 2 mainly includes a flashlight body 20, a support base 30 for supporting the flashlight body 20 and fixing it on the camera body, and enabling the flashlight to The main body 20 operates the driving device 40 .

[0021] The flashlight body 20 has a lamp body 23 and an upper cover 21 and a lower cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com