Third generation gleam image intensifier distinguishability adjusting device and method

A low-light image intensifier and adjustment device technology, applied in the factory adjustment of electric tubes/lamps, image conversion/image amplification tubes, screen tubes, etc., can solve the problem of high cost and increase the cathode input window of the third-generation low-light image intensifier Processing difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

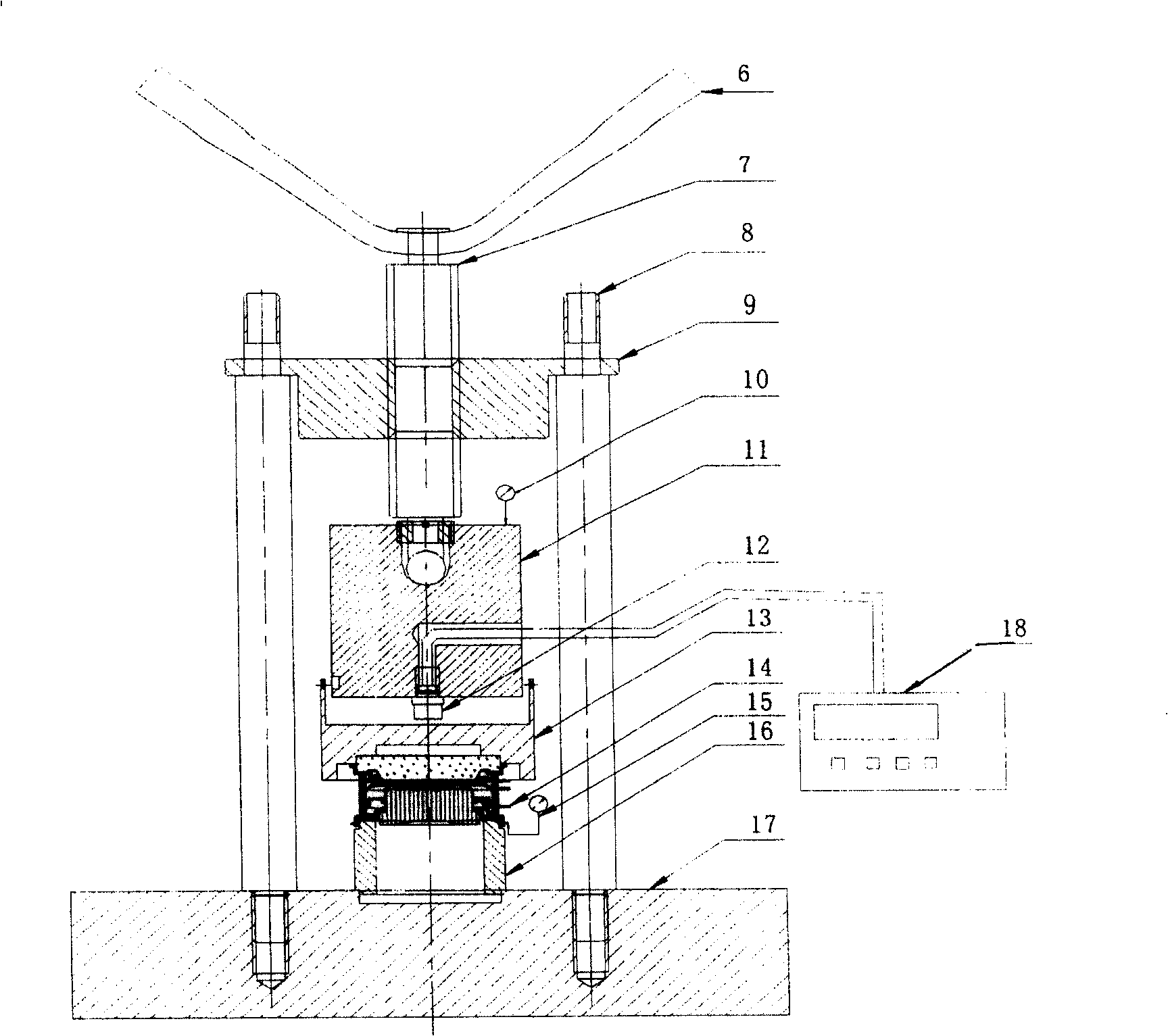

[0011] as figure 1 As shown, the preferred embodiment of the three-generation low-light image intensifier resolution adjustment device of the present invention includes: a piezoelectric digital display pressure sensor made up of a sensitive head 12 and a digital display 18, two precision size monitors 10 and 15, Working platform 17, pressure applying handle 6, pressure transmission rod 7, three support rods 8, rigid pressure head 11, fixed plate 9 with central screw hole, cathode assembly fixture 13, tube body positioning fixture 16. The piezoelectric digital display pressure sensor is produced by Zhonghang Electric Measuring Instrument Co., Ltd., and the two precision size monitors 10 and 15 are produced by Mitutoyo Corp. The model is Absolute ID-C150MB. The working platform is milled flat with 50kg cast iron Cylinder, the parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com