Lubricating structure for closed compressor baffle plate

A technology of lubricating structure and compressor, applied in rotary piston machinery, rotary piston/oscillating piston pump parts, mechanical equipment, etc., can solve the problem of compressor function decline, compressor reputation decline, and electric component input force increase. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

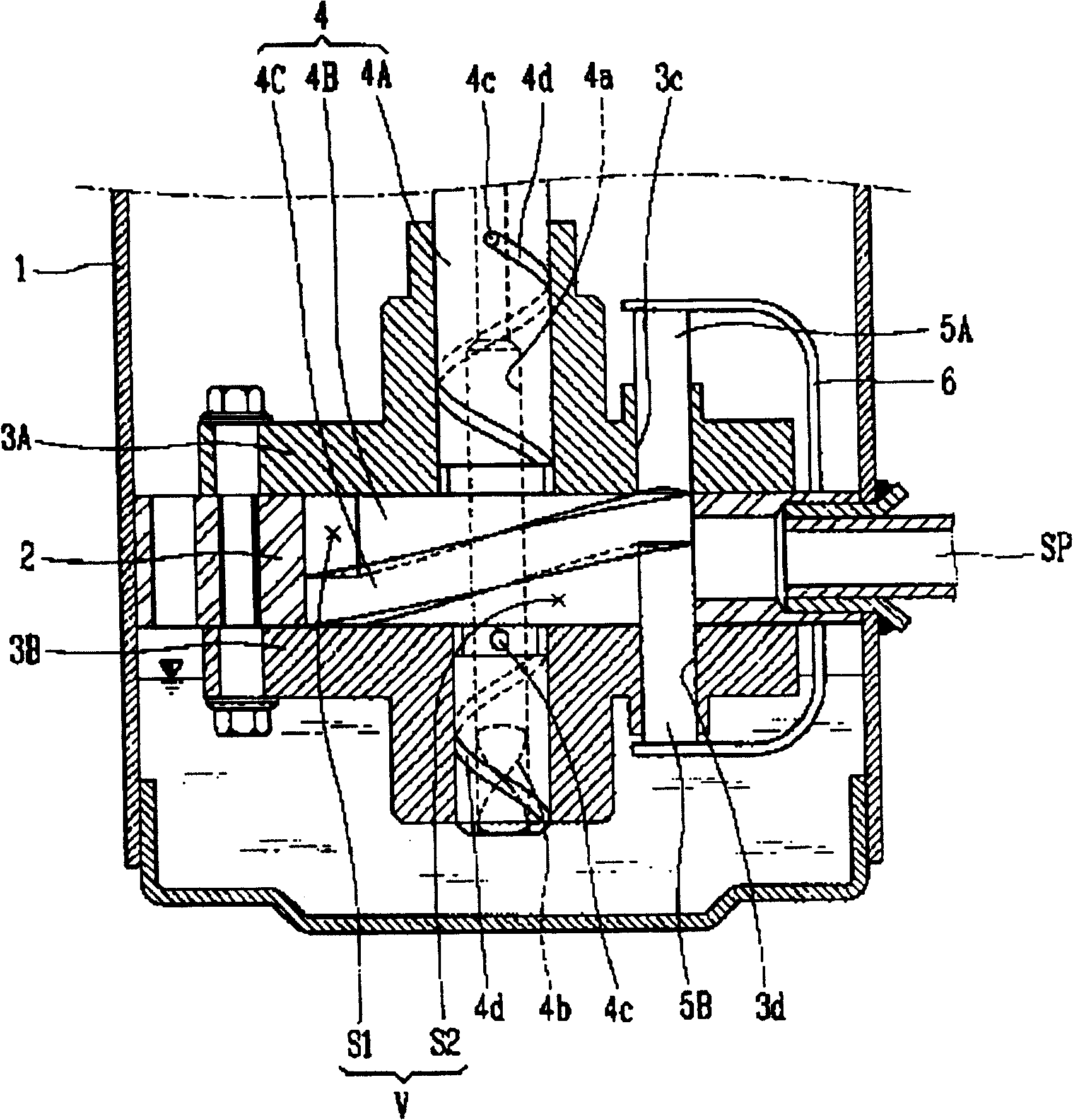

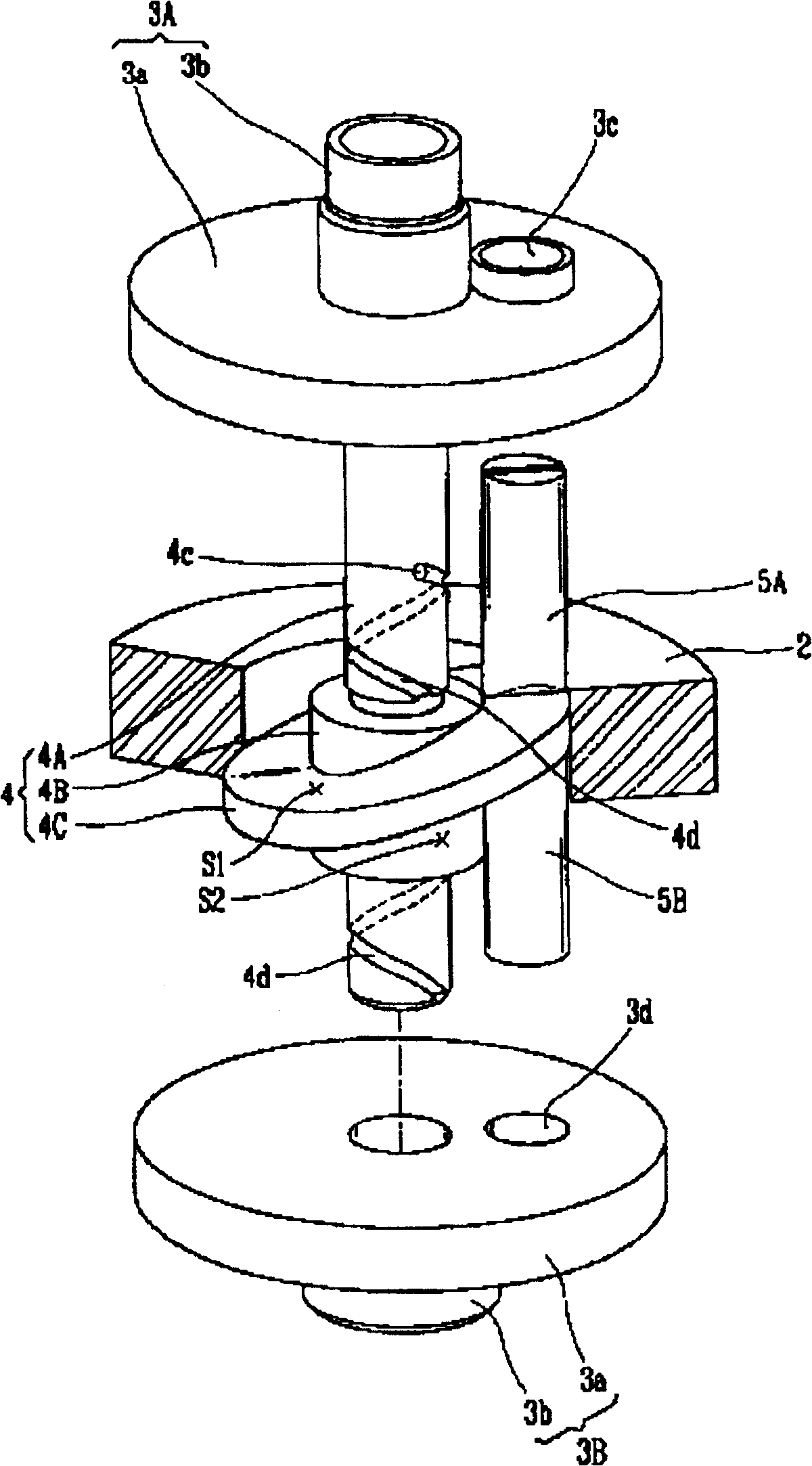

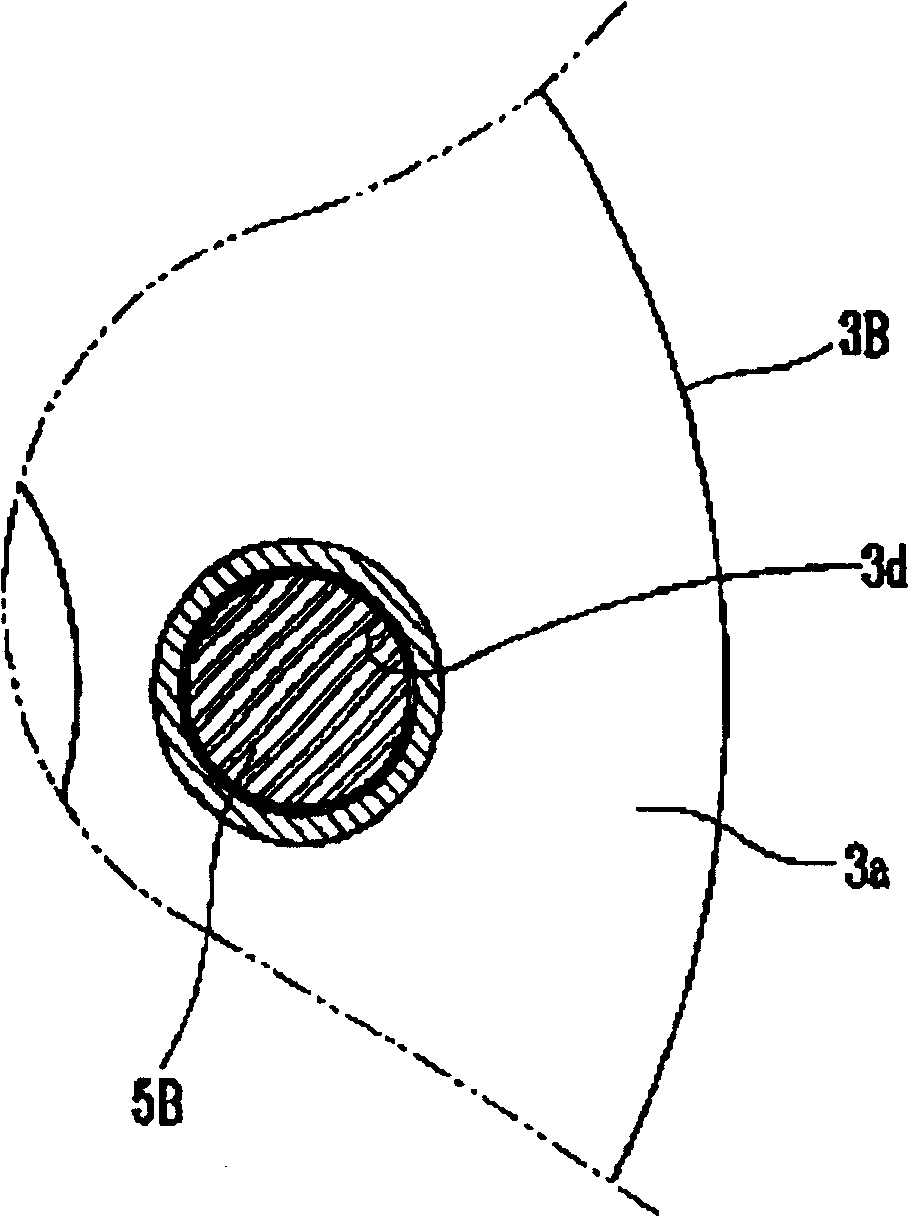

[0026] Figure 4 It is a partial cross-sectional schematic diagram of the hermetic compressor provided by the present invention. Figure 5 and Figure 6 It is a longitudinal sectional view and a schematic plan view of the compression parts in the hermetic compressor provided by the present invention. Figure 7 is along Figure 6 The cross-sectional view made by the I-I line in . The compression member is constituted by the air cylinder 12 , the first bearing plate 13A, the second bearing plate 13B, the rotating shaft 14 , the first flap 15A, the second flap 15B, and the flap spring 16 . Wherein, the cylinder 12 is fixed on the lower half of the shell 11, and its inside is provided with an inner space V for compressing refrigerant gas; the first bearing panel 13A and the second bearing panel 13B are mounted on the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com