Light-emitting device and method for manufacturing same

A technology for light-emitting devices and light-emitting surfaces, which is applied to lighting devices, semiconductor devices of light-emitting elements, light sources, etc., can solve problems such as inability to use, and achieve the effect of small difference in chromaticity characteristics and suppressing chromaticity deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

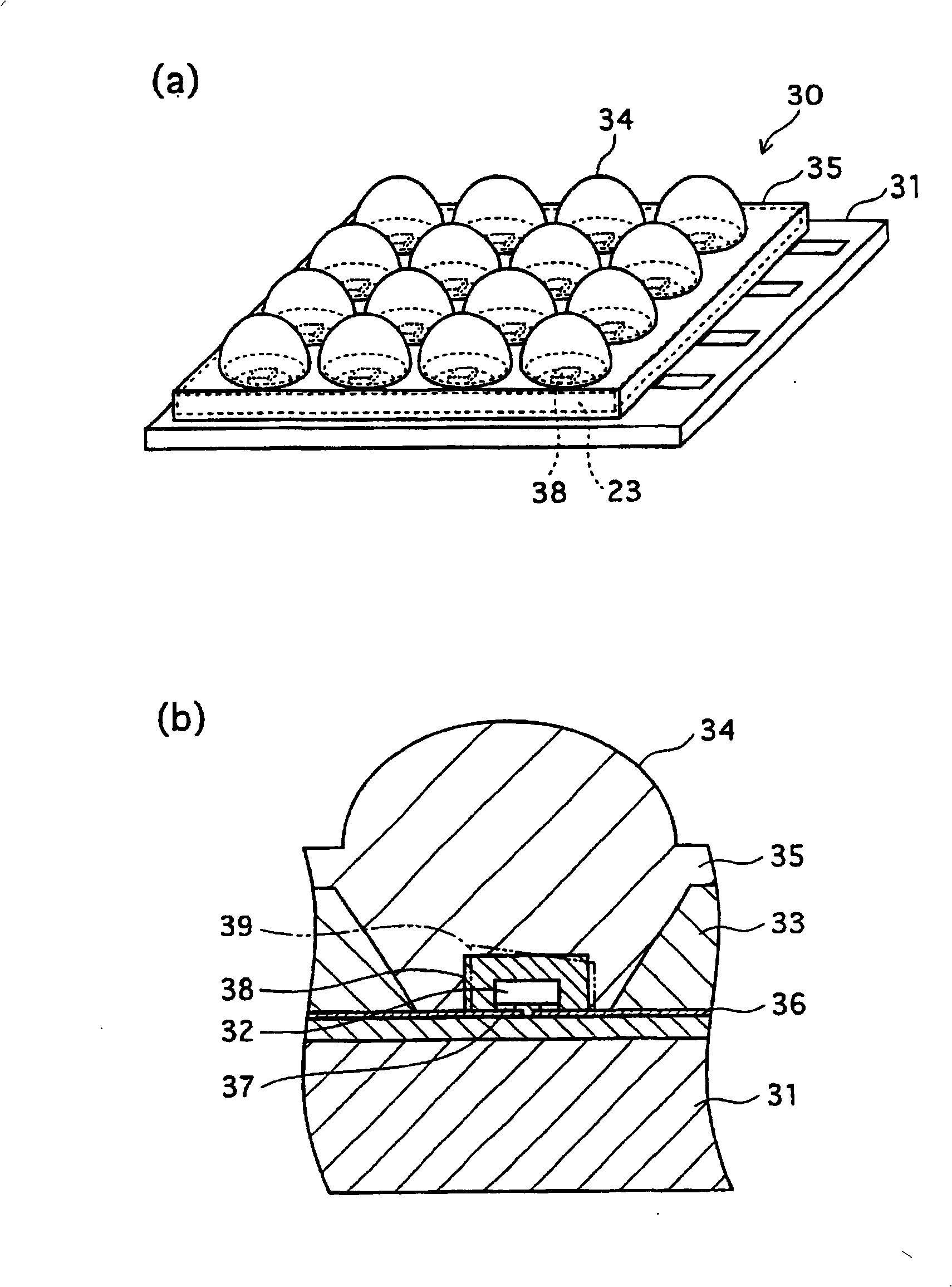

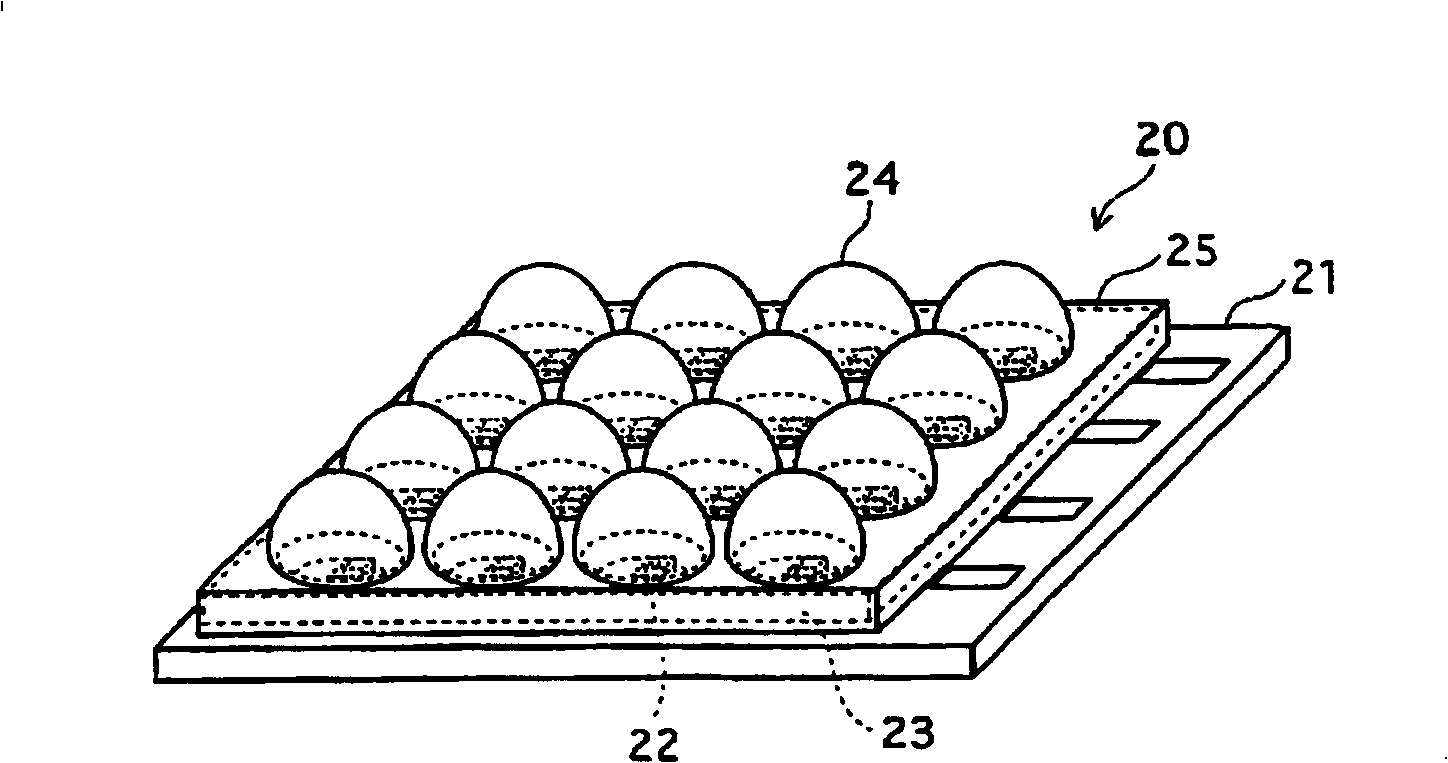

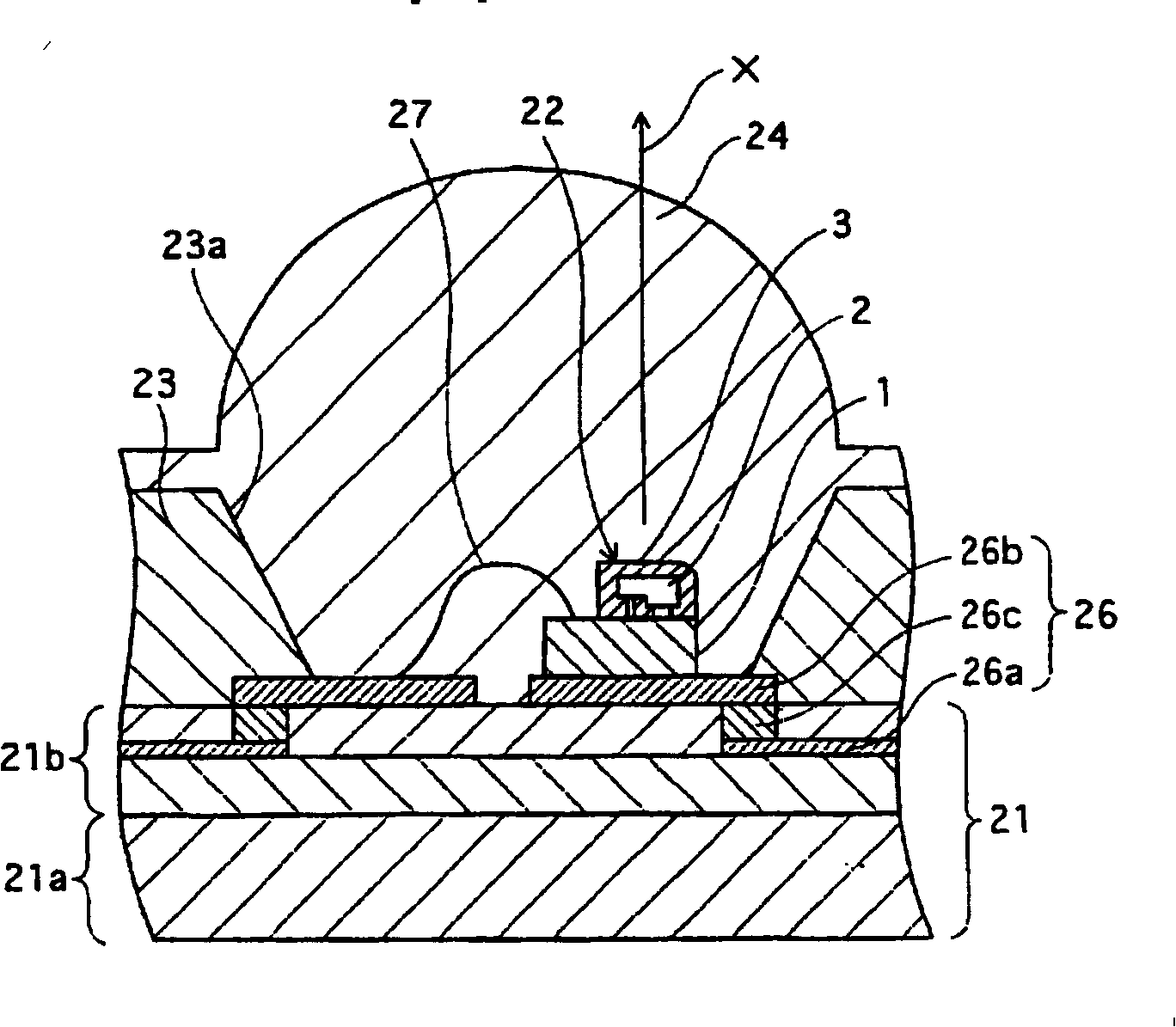

[0064] according to figure 2 and image 3 The configuration of a lighting device as a light emitting device according to Embodiment 1 of the present invention will be described. figure 2 It is a perspective view of the light emitting device according to Embodiment 1 of the present invention. image 3 is a partially enlarged cross-sectional view of the light emitting device.

[0065] Such as figure 2 and image 3 As shown, the lighting device 20 is composed of a substrate 21, a plurality of semiconductor components 22 mounted on the substrate 21, a reflective frame 23 with an opening at the position where the semiconductor component 22 is disposed on the substrate 21, and a reflective frame 23 formed to cover and The resin layer 25 which forms the convex lens part 24 in the light emitting direction of the semiconductor element 22 is comprised.

[0066] In addition, in the description of the lighting device according to Embodiment 1, the image 3 The light emitting dire...

Embodiment approach 2

[0115] according to Figure 14 The configuration of a lighting device as a light emitting device according to Embodiment 2 of the present invention will be described. Figure 14 It is a plan view of a light emitting device according to Embodiment 2 of the present invention.

[0116] The lighting device according to Embodiment 2 of the present invention is characterized in that figure 2 The configuration of the semiconductor component 22 of the lighting device shown is formed so that the positional relationship between the semiconductor light emitting element and the wire connection area of the auxiliary mounting element loaded with the semiconductor light emitting element is different from that of other semiconductor components arranged adjacently in columns or rows. different.

[0117] again, in Figure 14 in, right with figure 2 The same symbols are assigned to the same structures, and explanations are omitted.

[0118] Such as Figure 14 As shown, the lighting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com