Pulling rod connecting fastener of braider

A technology of draw bar and connecting buckle, which is applied in the field of warp knitting machines, can solve the problems of lack of swing and rotation measures, inconvenient loading and unloading, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

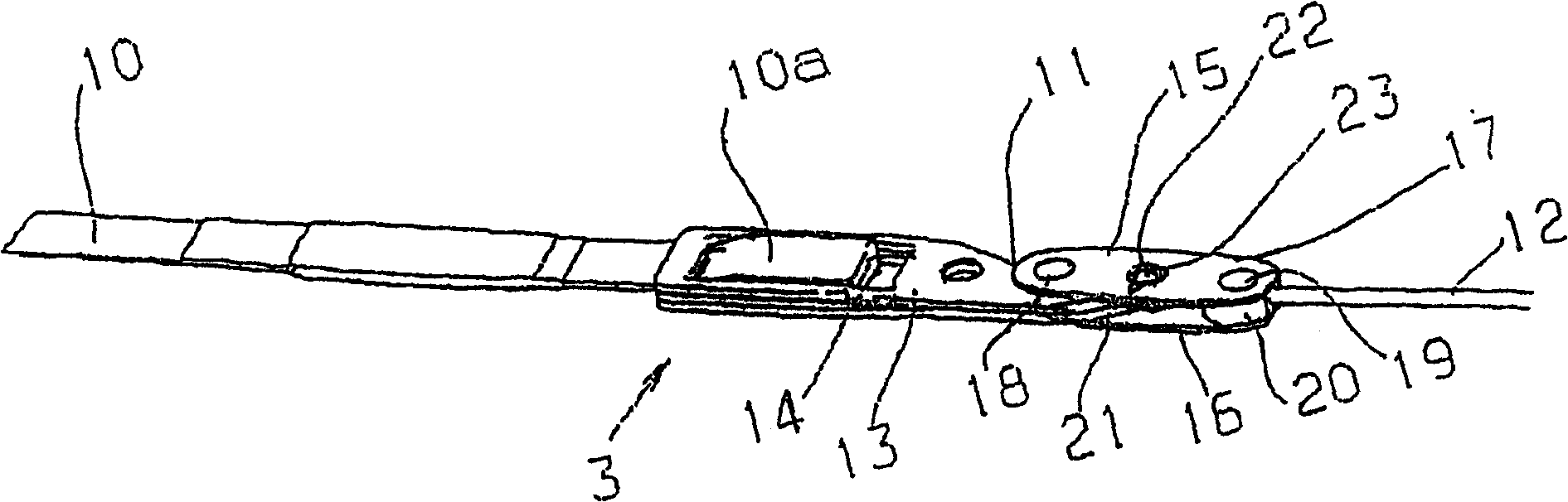

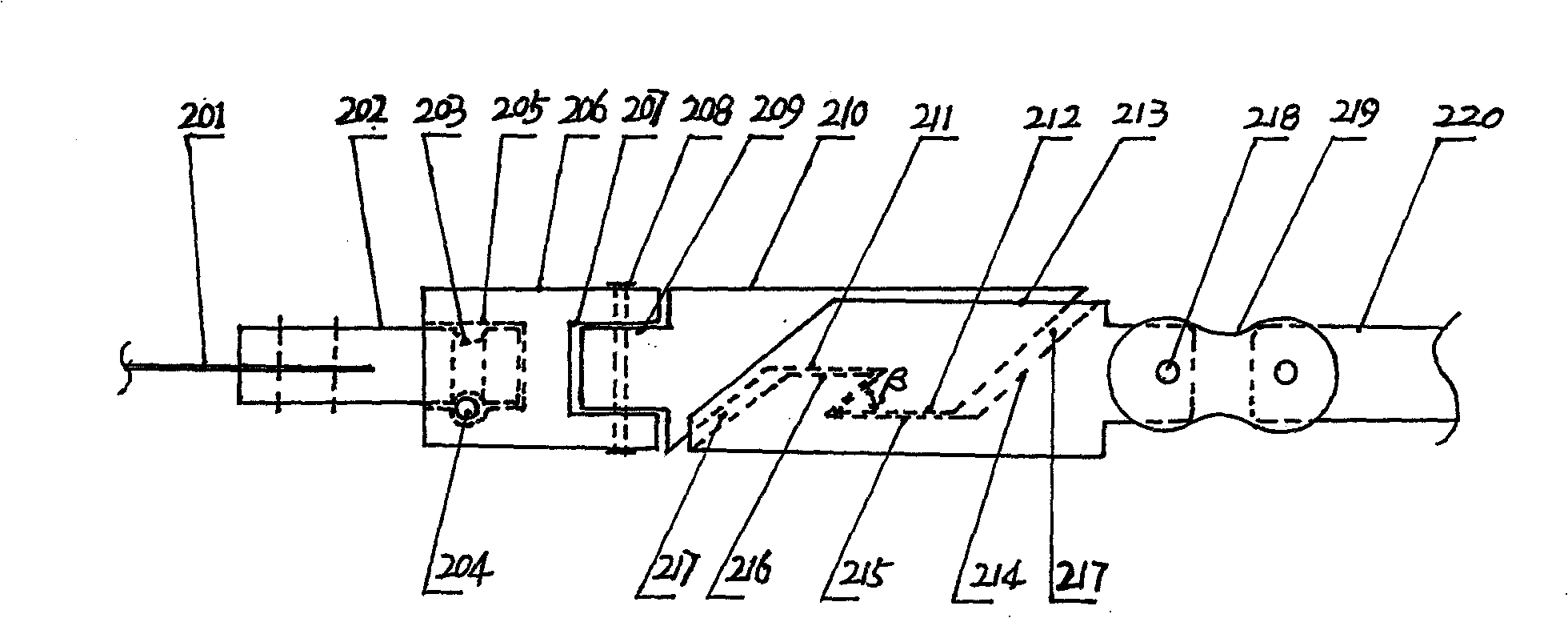

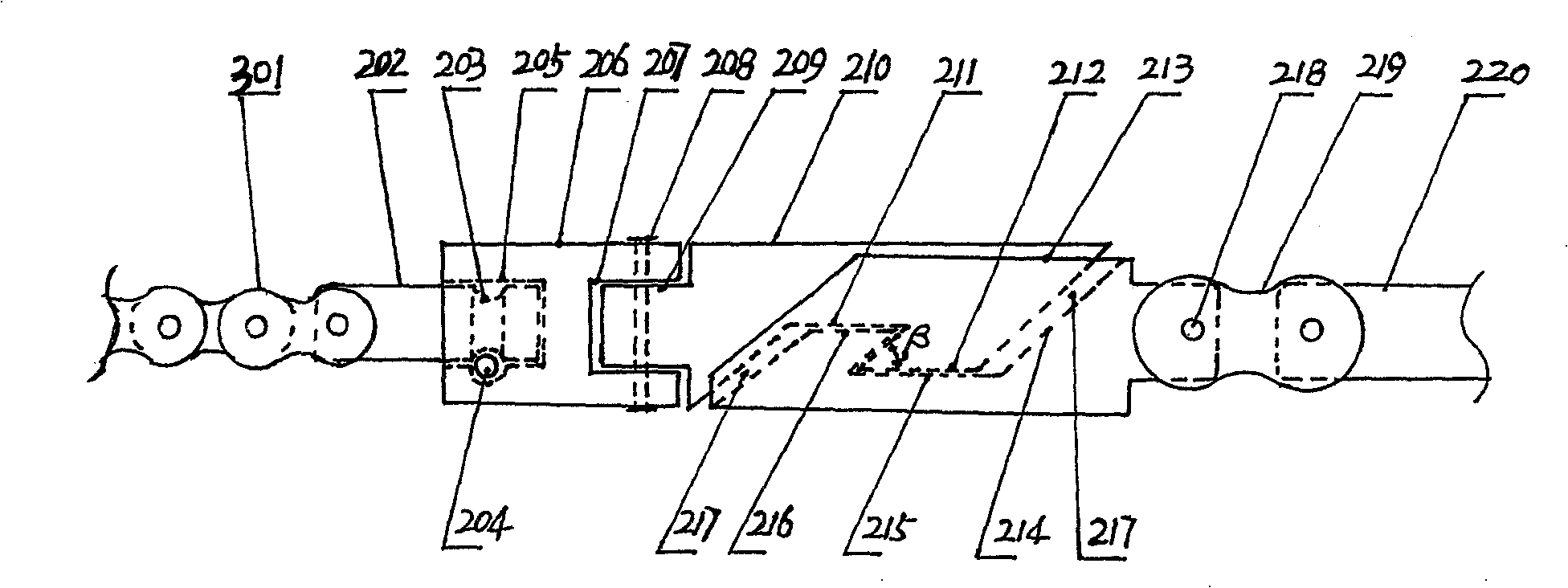

[0009] See attached figure 2 , 201 in the figure is a steel belt, 202 is a rotary joint, 203 is a groove, 204 is a pin, 205 is a counterbore, 206 is a joint seat, 207 is a concave table, 208 is a shaft, 209 is a boss, 210 is a hook , 211 is the inverted tooth groove of the hook 210, 212 is the inverted tooth of the hook 210, 213 is the baffle plate, 214 is another hook, 215 is the inverted tooth groove of the hook 214, 216 is the inverted tooth of the hook 214, 217 is two The gap between the hooks, 218 is an axle, 219 is a chain link, and 220 is a drawbar. attached image 3 301 in it is a chain, and other labels are the same as figure 2 same. The connecting buckle for the lateral movement of the drawbar of the present invention is mainly composed of two hooks 210 and 214, two baffle plates 213, a joint seat 206 and a swivel joint 202, and one end of the two hooks 210 and 214 is respectively provided with a The boss with shaft hole, the other end is respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com