Cam rotary feeder of automatic assembler for milled assembled cam shaft

An assembled, camshaft technology, used in assembly machines, valve devices, feeding devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

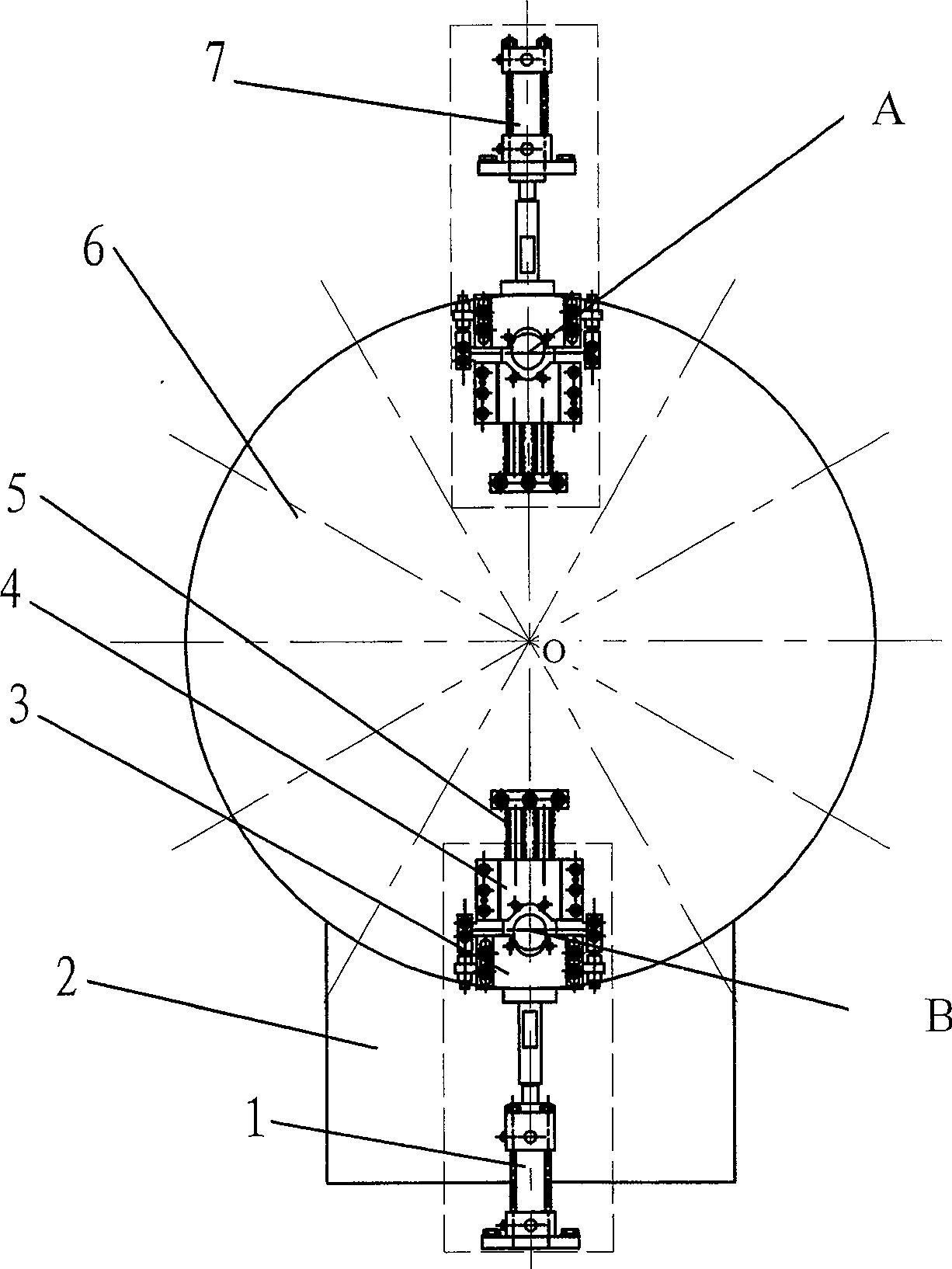

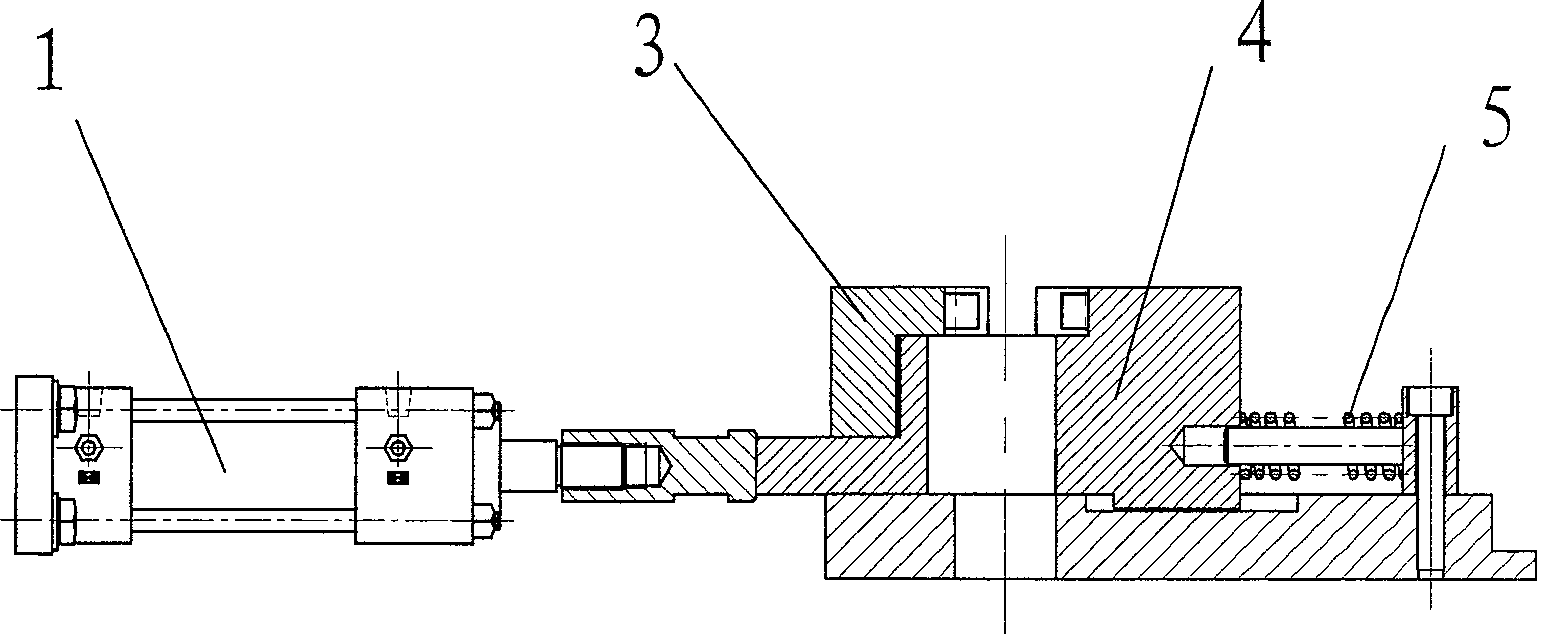

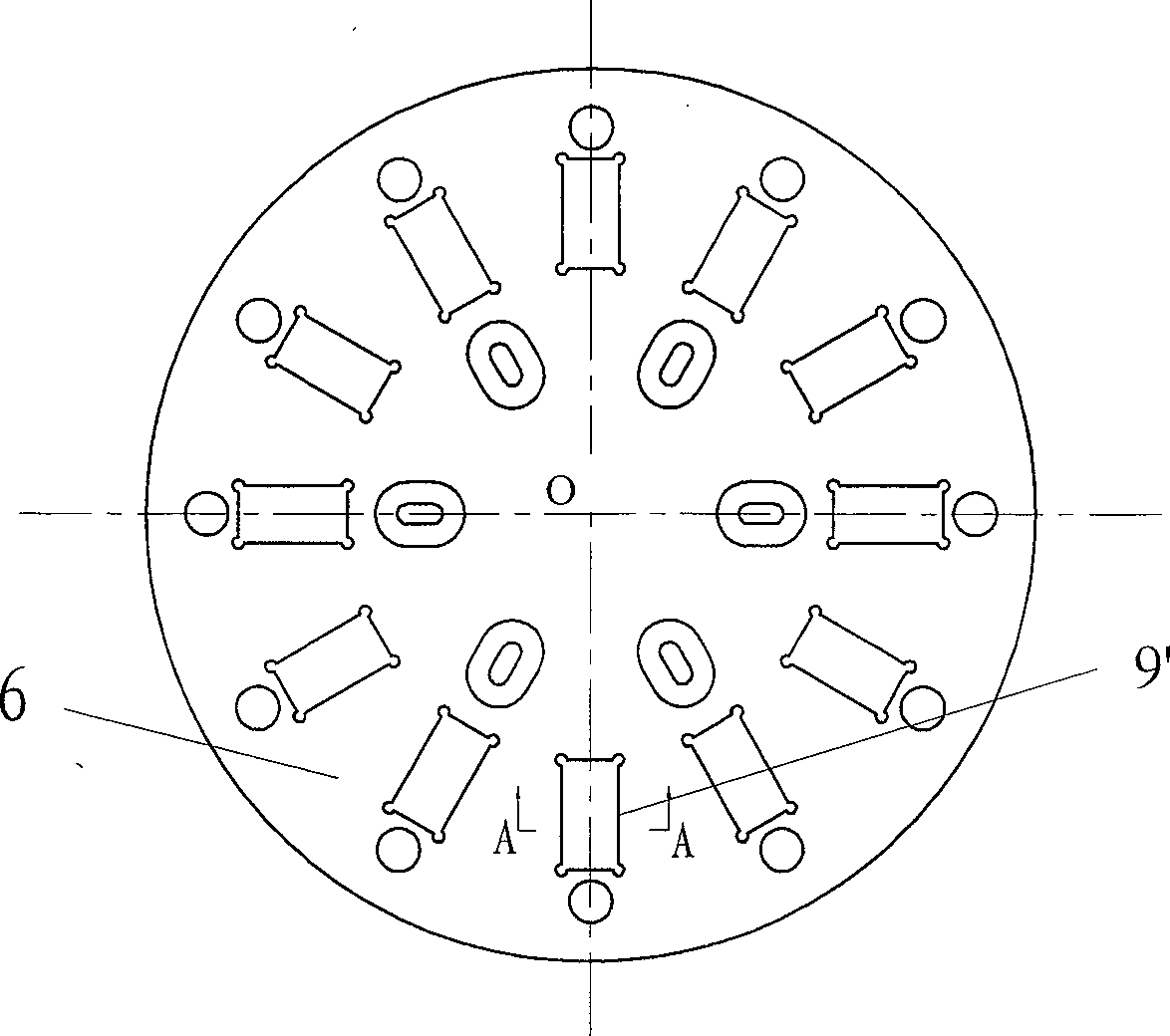

[0019] The rotary disc 6 is placed on the numerically controlled rotary table 2 and can be driven to rotate by the rotary table. A guide rail groove for the positioning and sliding of the moving block 4 is provided on the rotary disc to ensure that the moving block moves along the guide rail groove and the moving block guide rail 9 to ensure assembly accuracy. The moving block guide rail 9 is fixed on the rotary disc 6 .

[0020] The cam feeding oil cylinder 1 is fixed on the outer supporting point, and the cylinder push rod can push the movable block 4 to move toward the center O of the rotary disk along the guide rail groove of the rotary disk 6 and the movable block guide rail 9 . The moving block guide rail 9 is fixed on the rotary disk 6 .

[0021] The cam unloading oil cylinder 7 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com