A method for measuring the axial center of mass of a two-degree-of-freedom gyroscope rotor assembly

A measurement method and a technology of degrees of freedom, applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., can solve the problems of customized special measuring equipment that cannot meet the requirements, gyroscope parts are scrapped, and the static balance is large, so as to save Manpower and material costs, avoiding repairs or even scrapping, and reducing the effect of temperature drift coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

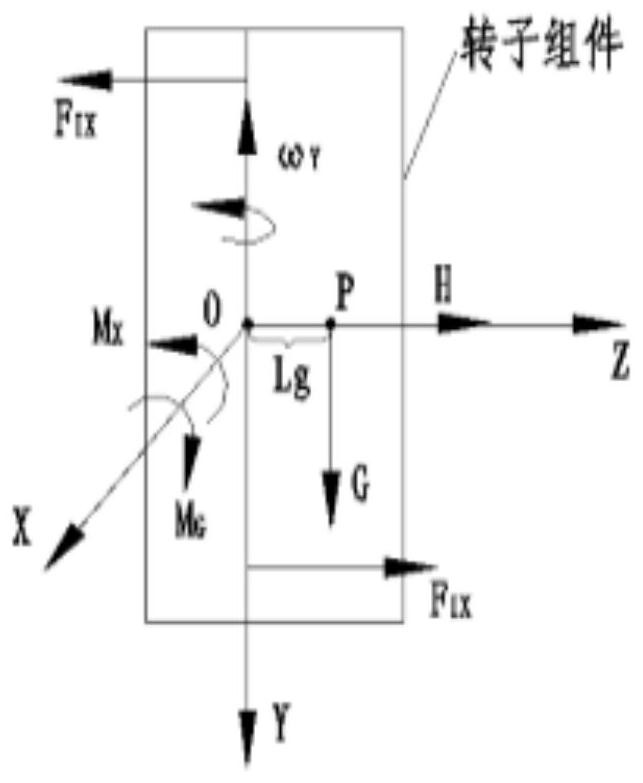

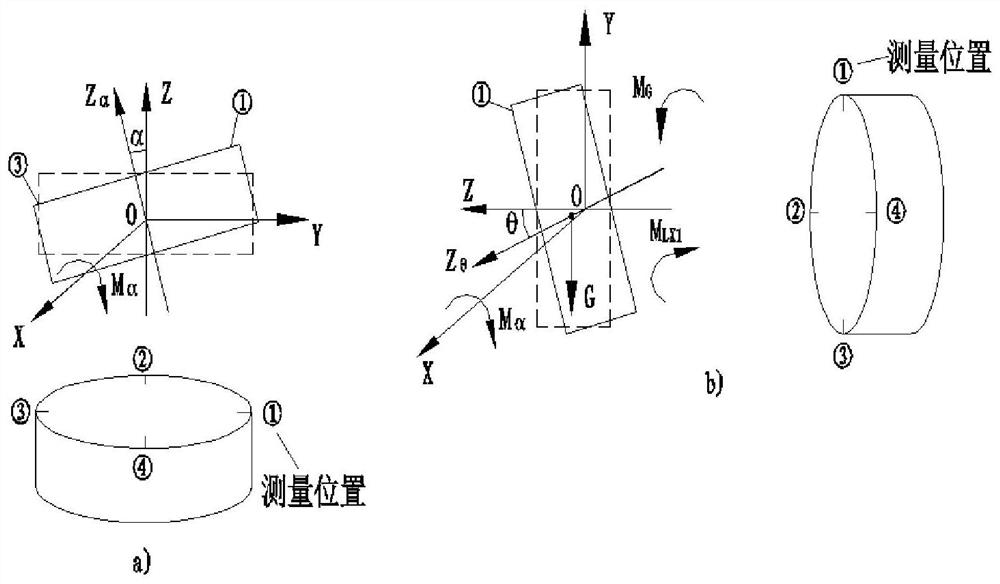

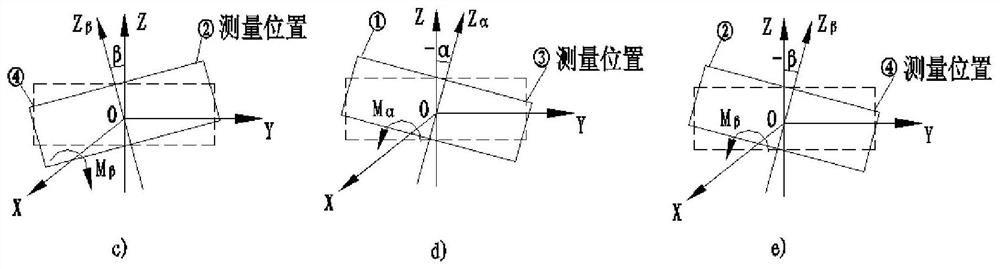

[0035] The present invention is suitable for a two-degree-of-freedom gyroscope, and builds a gyroscope rotor mass center measurement system by means of a gyroscope test system with a force feedback rebalance circuit, focusing on the precise measurement of the axial mass center position of a gyroscope rotor assembly.

[0036] A method of measuring the precise position of the axial center of mass of a gyro rotor assembly. The physical composition of its measurement system includes a gyro test system, a DC linear power supply, a variable resistance box, and a commutation board. The method is realized through the following steps: firstly, the gyro open-circuit state is in a horizontal posture, at this time, the gyro axis is parallel to the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com